Tools and Materials

・PCB (phenolic resin)

・Soldering iron

・Solder

・Chip LED (1206)

・1k ohm chip resistor (1206)

・Battery box

・Button battery (CR2032 3V)

・Tweezers

・SRM-20 (CNC milling machine)

・Computer

using MDX-20

Creating the circuit data

Here we explain how to make the circuit data for the LED.

Install Eagle

Install Eagle to your PC from the following URL.

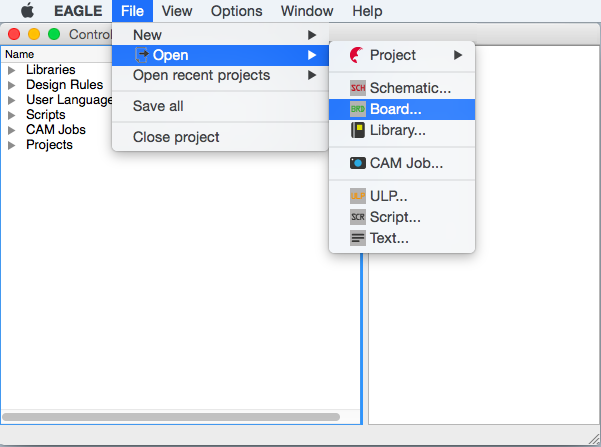

Open the Circuit Board's File in Eagle

・Open Eagle.

・From the menu at the top of the screen,

select [File] → [Open] → [Board] to open the [.brd file].

・From the menu at the top of the screen,

select [File] → [Open] → [Board] to open the [.brd file].

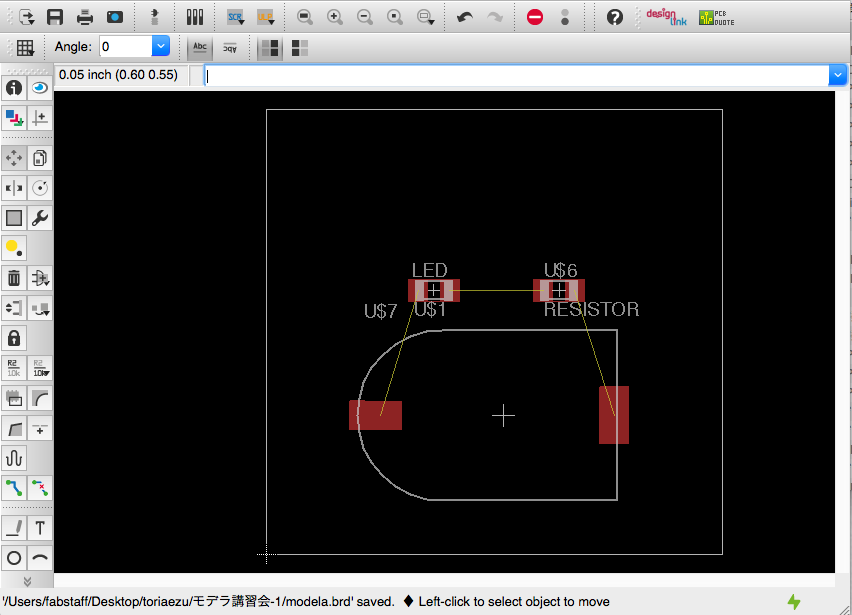

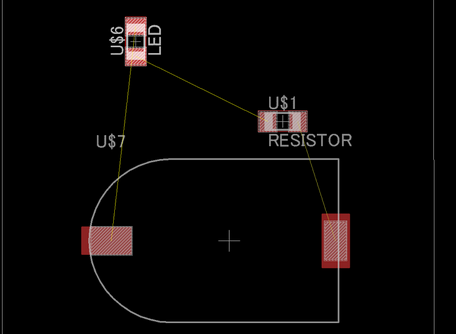

Place the Parts

Decide where to place the battery box, LED, and resistor.

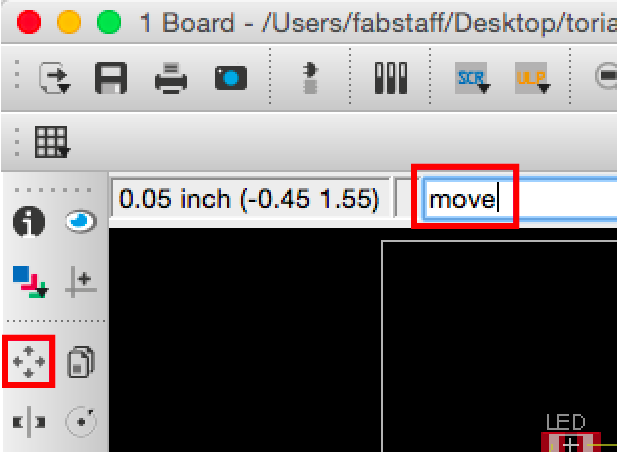

There is a command line at the top of the window.

Type in “move”, press Enter and click the components to move them.

(Or you can click the [move command] on the toolbar at the left side of the window)

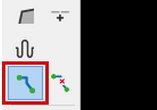

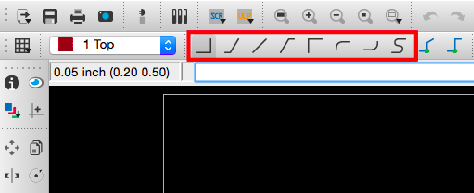

Wire the Parts (1)

When you have finished arranging all of the components, wire them together.

Execute the Route command to connect each of the components’ pins.

Once you click one end of a component, the end of another component will be highlighted. Click and create a path to connect those ends.

Wire the Parts (2)

First, connect the negative end of the LED to the negative end of the battery box.

※ Do not click and drag. Just click.

※ Be careful not to double-click or the wiring will stop at that point.

※ Make sure that the red lines DO NOT cross over.

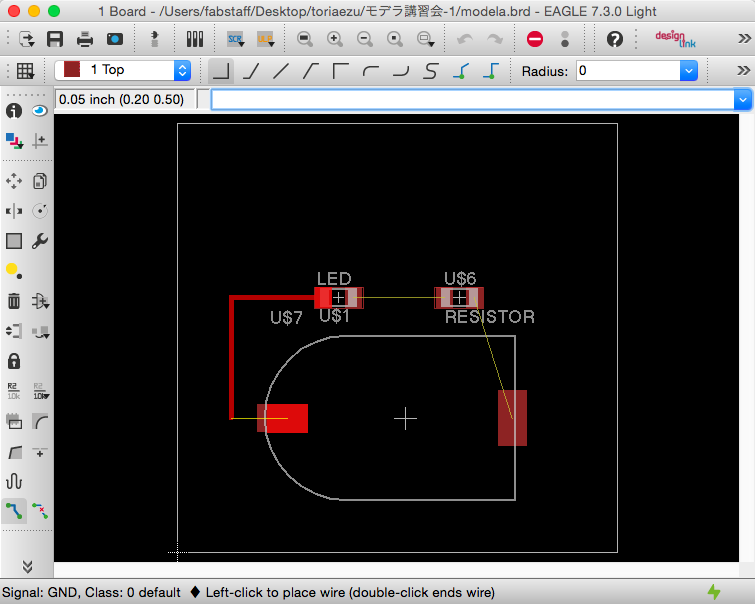

Wire the Parts (3)

Connect the rest of the components.

・Positive end of the LED → One end of the resistor

・Other end of the resistor → Positive end of the battery box.

right-click during wiring, or use the toolbar at the top of the window.

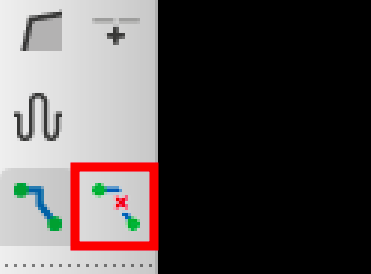

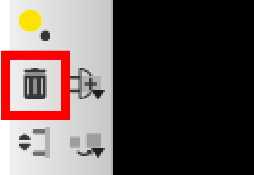

Re-wiring

If you want to erase the wiring, execute the Rip Up command and click the wire.

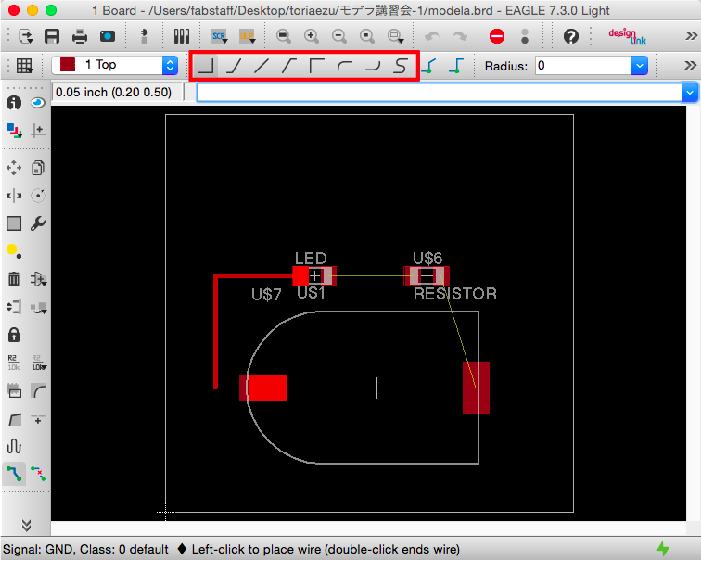

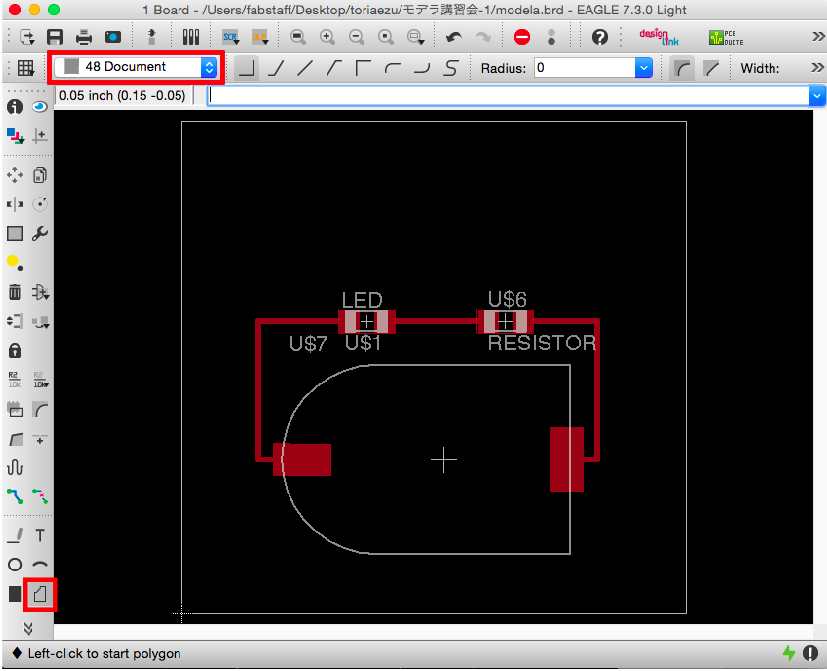

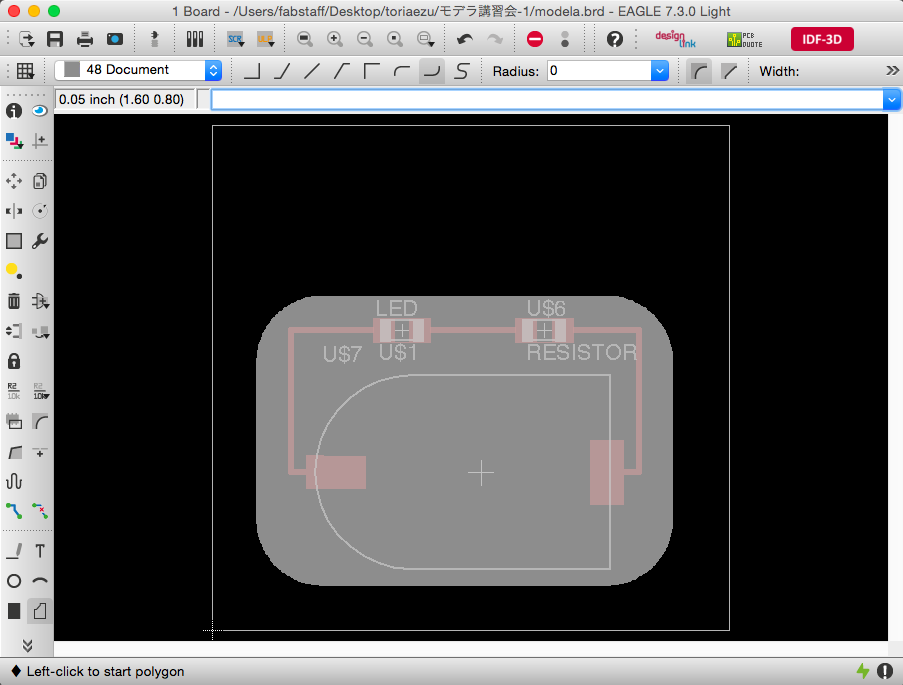

Create the Outline of the Board (1)

Execute the Polygon command by typing "Polygon" or clicking the [Polygon command].

From the top of the window, change the layer form [1 Top] to [48 Document]

※ The outline of the board has to be saved on a different layer in order to save it separately from the other data,

Create the Outline of the Board (2)

Draw the outline by clicking several times.

When the beginning and end of the line is connected, the inner area will turn into a transparent white color and the shape will be finalized.

※ If you press ESC before the shape is finalized, all of the lines will be erased.

Erase the Outline

To erase the outline, execute the Delete command.

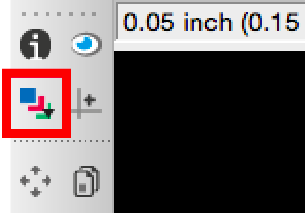

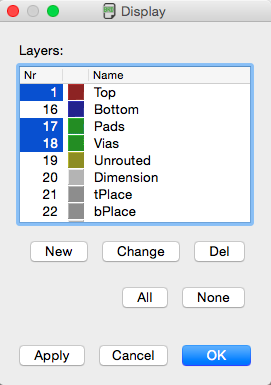

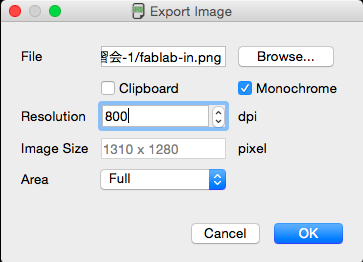

Export the PNG File (1)

Now, we will export the PNG file of the circuit's traces.

Select the numbers of [1 Top], [17 Pads] and [18 Vias] to show only the traces of the circuit, and press [OK].

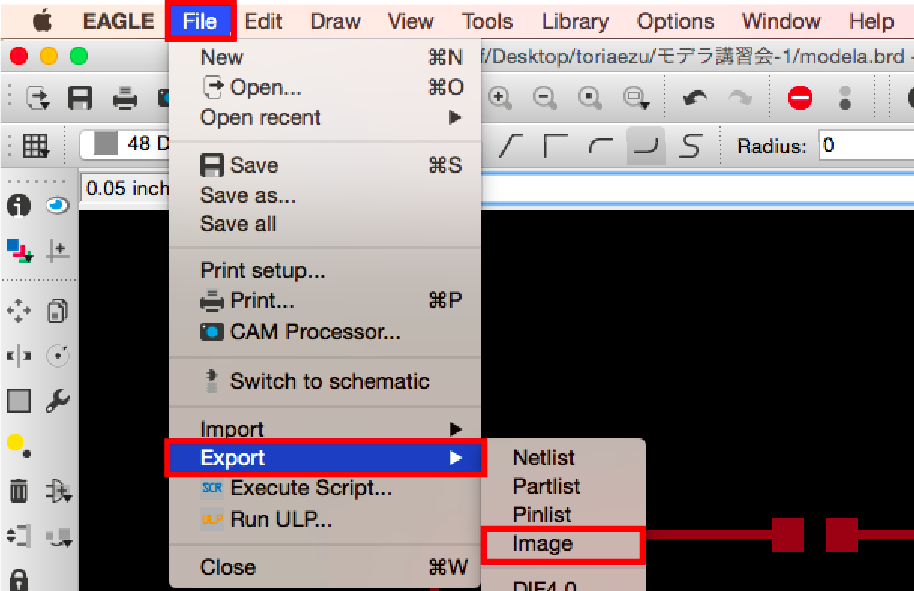

Export the PNG File (2)

From the menu at the top of the screen, select [File] → [Export] → [Image] to export the circuit’s data.

Browse and select the place to save the file, type the file’s name and save it as a png file.

Check [Monochrome], change the resolution to [800 dpi] and press [OK] to save.

Export the PNG File (3)

Select only the [48 Document] layer and repeat the steps from [Export to png(2)] to save the outline file.

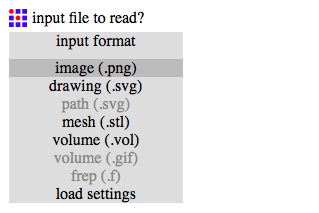

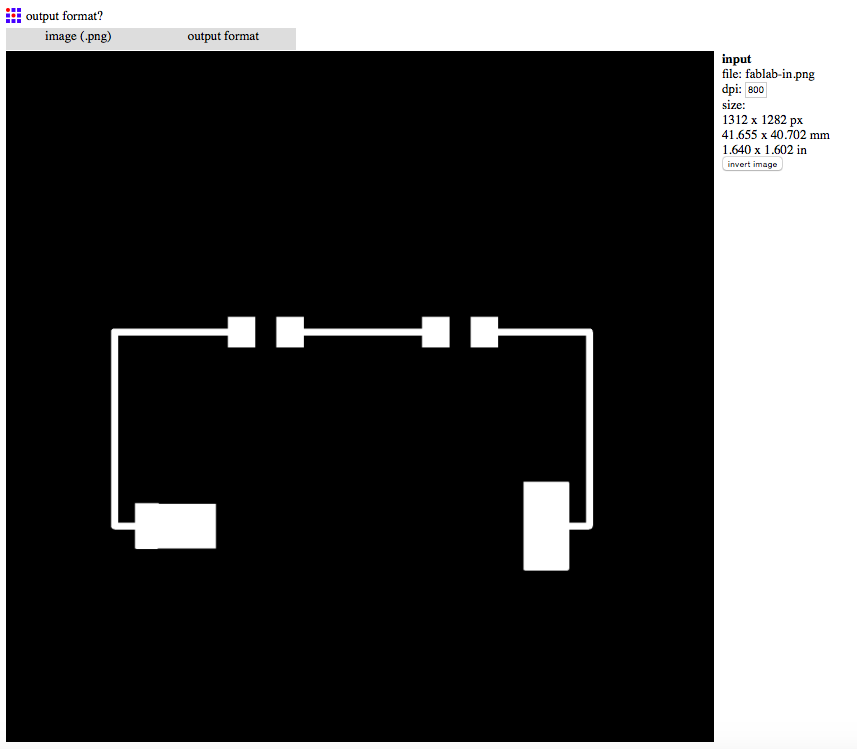

Fab Modules

Fab Modules is an online, open source, CAM software which we will use to convert the [.png] file to [.rml] file (path data).

Go to the site and follow the steps below.

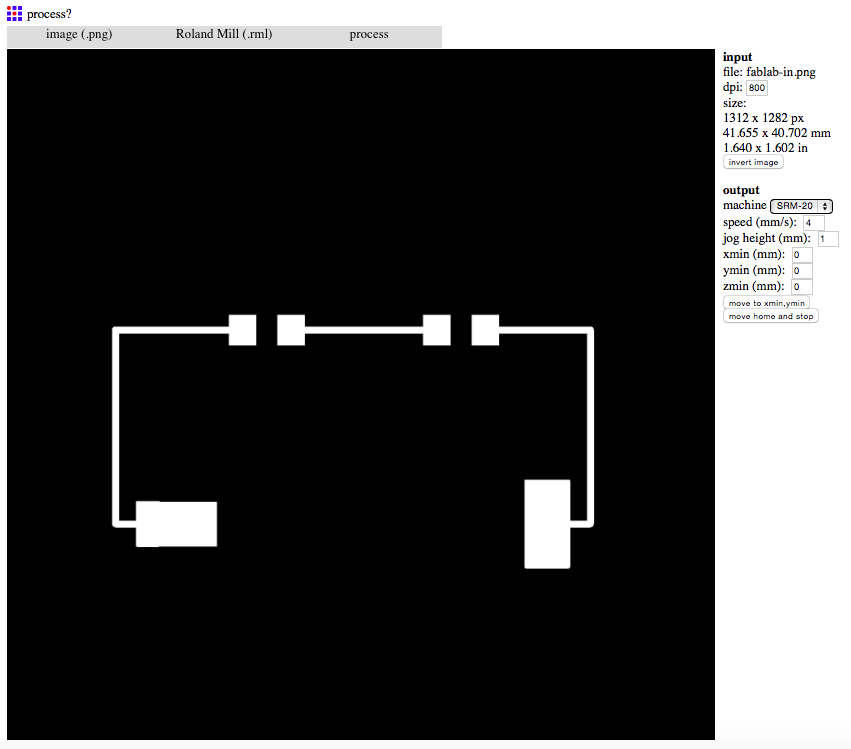

Export the RML File (1)

Open an internet browser and go to the following link.

fabmodules.org

fabmodules.org

Click [input format] to show the extension names.

Select [image(.png)].

Select the png file and click [Open].

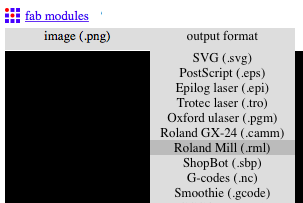

Export the RML File (2)

Click [output format] and select [Roland Mill(.rml)].

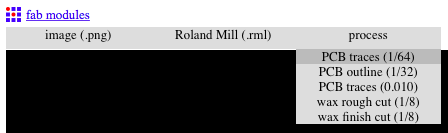

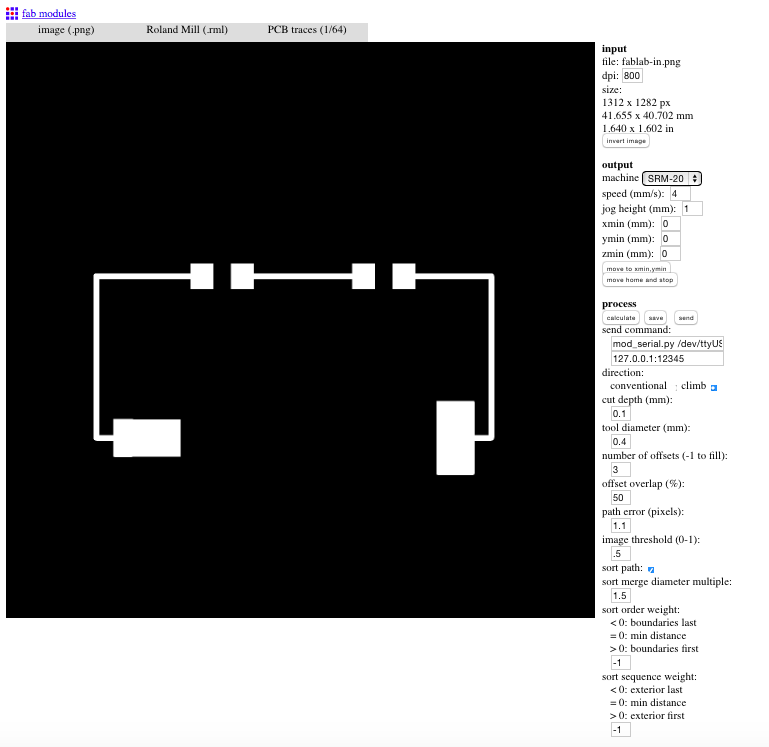

Export the RML File (3)

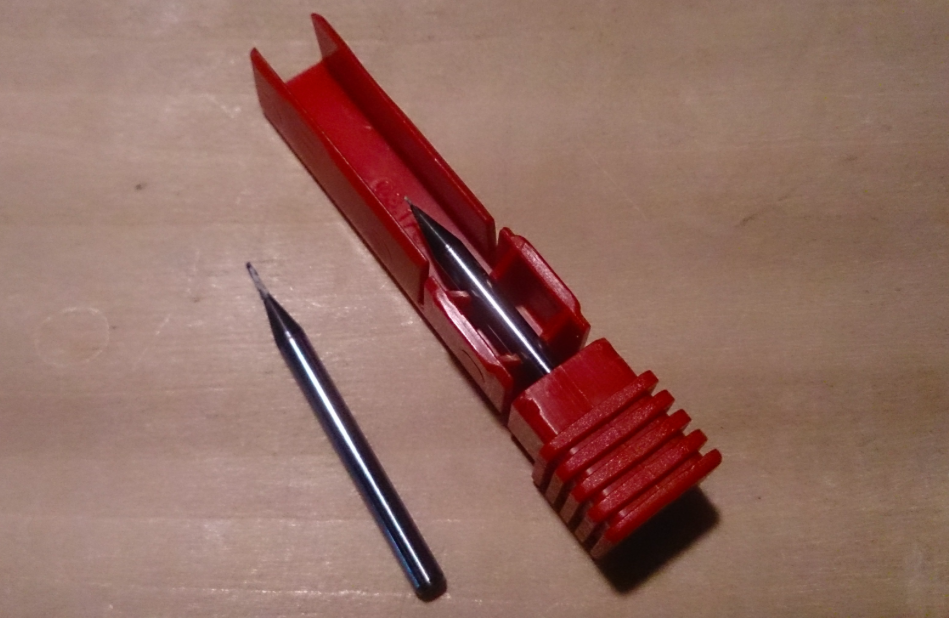

Select the bit's size by clicking [process] and selecting [PCB traces (1/64)].

※For exporting the outline data, select [PCB outline (1/32)].

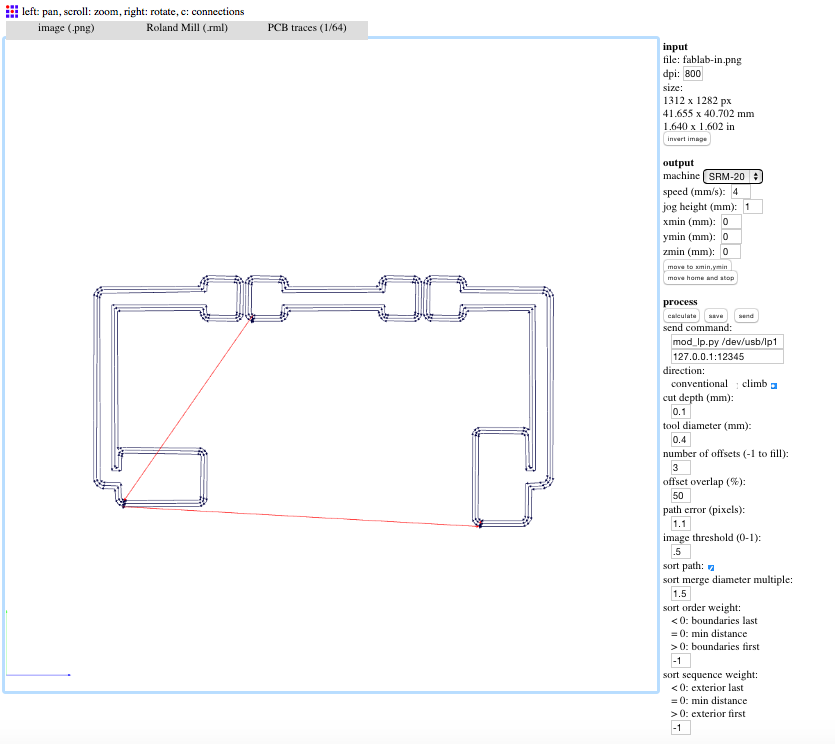

Export the RML File (4)

Click the [calculate button] located under process, to create the path data.

Once the tool path data appears on the left area of the screen, click the [save button] to download the data.

Export the RML File (5)

Repeat steps (1) to (4) to create and save the outline’s path data.

※For exporting the outline data, select [PCB outline (1/32)] in step (3).

Save the Data on a USB

Save the [.rml] files on a USB.

Milling the LED Board With SRM-20

Here we explain how to mill the circuit board with the SRM-20.

We will use a software called [VPanel] (provided by Roland) to export the [.rml] data.

Turn on the SRM-20.

Turn on the SRM-20.

Turn on the computer that is connected to the SRM-20 and open [VPanel].

Open VPanel

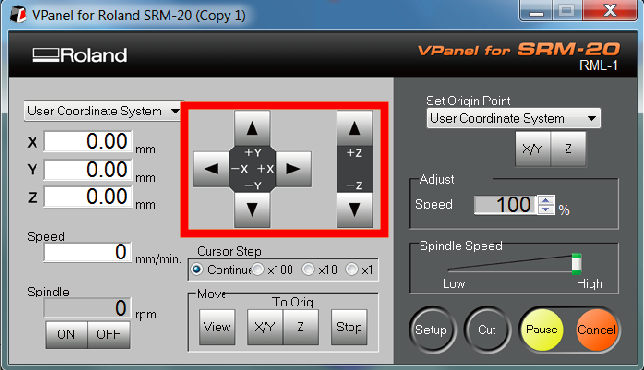

Here we use VPanel to set the bit’s origin. There are two settings.

This time we will use the User Coordinate System.

- Machine Coordinate System

- User Coordinate System

This time we will use the User Coordinate System.

Adjust the Bit’s Origin (1)

After inserting and securing a 1/64” bit in the spindle, click the [X/Y arrows] to set the origin of bit. Carefully click the [Z arrow] and lower the bit until it is slightly above the board.

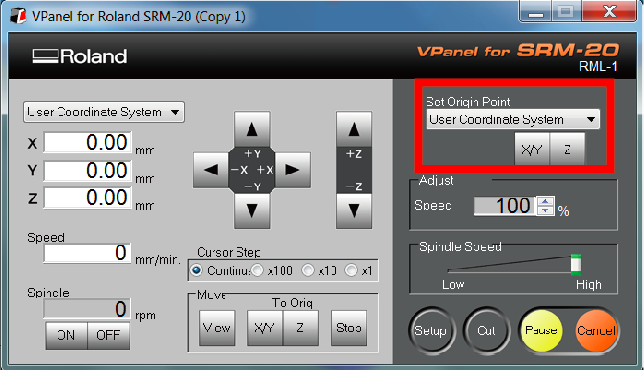

Adjust the Bit’s Origin (4)

Click the [X/Y button] and [Z button] under Set Origin Point.

Adjust the Bit’s Origin (2)

Now we adjust the bit so that it touches the board.

While holding the bit with one hand, loosen the setscrew on the spindle with a hexagon wrench, carefully place the bit on the PCB, and gently tighten the setscrew.

While holding the bit with one hand, loosen the setscrew on the spindle with a hexagon wrench, carefully place the bit on the PCB, and gently tighten the setscrew.

Adjust the Bit’s Origin (3)

※ DO NOT tighten the setscrew with too much force or you may damage it.

※ DO NOT drop the bit on the board or the tip may break.

※ DO NOT drop the bit on the board or the tip may break.

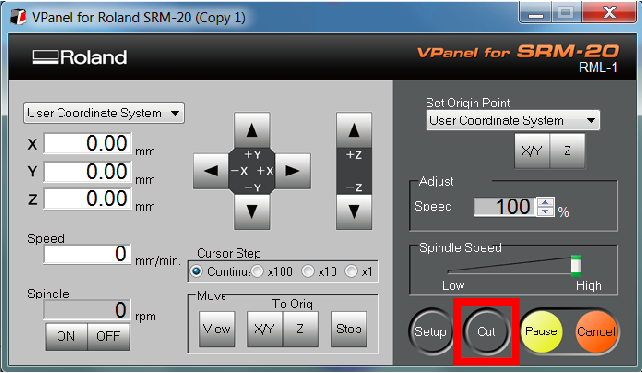

Send the Data to SRM-20 (1)

Import your data by clicking the [Cut] button.

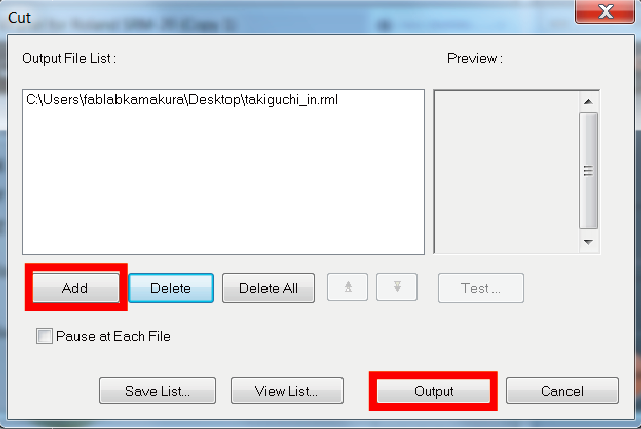

Send the Data to SRM-20 (2)

Click [Add] and select the [.rml file] for the circuit's traces.

When the [Output] button is pressed, the machine will begin to mill.

※If the previous files appear in the Output File List, delete them before opening the [.rml] file.

Change the Bit

For the outline of the circuit board, change the bit to 1/32”. Use the [Z arrows] and hexagon wrench to adjust the bit. Then, click only the [Z button] under Set Origin Point to re-set the bit’s origin.

※DO NOT forget to re-set the bit’s origin ([Z button]), or the bit may break.

※DO NOT forget to re-set the bit’s origin ([Z button]), or the bit may break.

Send the Data to SRM-20 (3)

Repeat the previous steps from Send the Cutting Data for milling the outline of the board.

( [Cut] → [Add] → [Select the .rml file] → [Output] )

Remove the Board (1)

When the milling is done, open the front window, loosen the 4 screws and take out the orange stage.

Remove the Board (2)

Use the solvent and scraper to remove the board

Remove the Board (3)

Pour the solvent between the orange stage and the PCB.

Insert the scraper between the stage and the PCB and carefully remove the board.

Mount the components / Solder

Begin to solder from the smallest components.

[LED] → [Resistor] → [Battery case]

※Be careful! The LED has polarity. The side with the green line is - (anode).

Solder the Components (1)

Flow a little amount of solder into one of the pads

Wet the soldering iron with a little solder. Press the tip of the soldering iron on a pad. Briefly press the solder on the board and flow it on the pad. Release the solder, then the soldering iron form the pad.

Wet the soldering iron with a little solder. Press the tip of the soldering iron on a pad. Briefly press the solder on the board and flow it on the pad. Release the solder, then the soldering iron form the pad.

Solder the Components (2)

With a tweezer, hold the small component and press it on the soldered pad.

Warm that pad until the component is connected to the board.

Solder the other pad.

Complete

Insert the battery.

If the LED turns on your circuit board is complete!

Tips for soldering

・Press the tip of the soldering iron on the board and warm it up before flowing in solder.

・Turn off the soldering iron whenever it isn’t being used.

・Turn off the soldering iron whenever it isn’t being used.