About the need knower(s)

Medical Condition

He sustained a C5 spinal cord injury due to a fall, resulting in quadriparesis (partial paralysis in all four limbs). He has limited fine motor control, low triceps strength, and poor body balance, making it difficult to perform daily tasks. He requires assistive support to enhance independence.

Causes and Challanges

- Limited function in all four limbs

- Requires support for daily activities

- Low triceps strength and poor body balance

Subject / Need(s)

Individuals with C5 spinal injuries struggle with gripping objects which become challenging, increasing dependency on caregivers. Existing solutions have limitations:

- Expensive & not affordable

- Complex to use and require excessive hand strength

- Lack customization for individual needs.

Idea(s)

The QuadTool Solution QuadTool:3D-printed adaptive gripping device designed to assist individuals with limited finger movement. It will be lightweight, ergonomic, and easy to use,allowing users to hold objects with minimal effort. The design may integrate mechanical linkages to improve functionality.

inspiration

Prototyping(s)

- Design & Development

- Materials & Printing Process

- Testing & Iterations

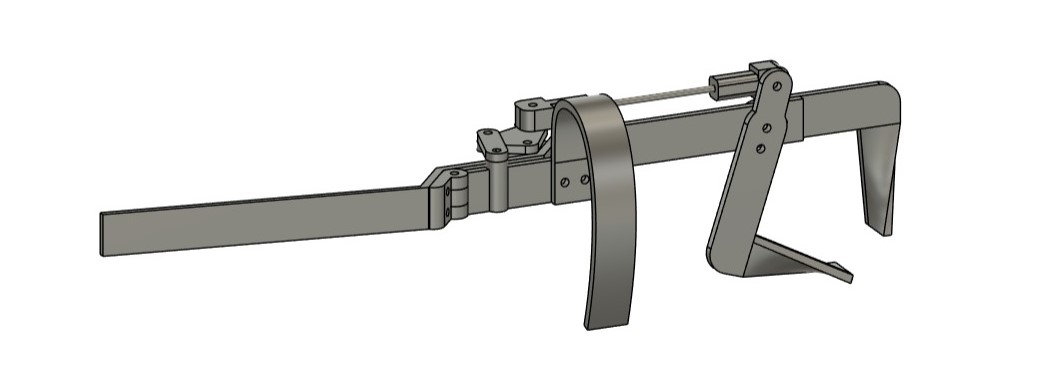

first prototype

Design & Development

The QuadTool was designed in SolidWorks with an ergonomic structure for easy grip. The model includes mechanical linkages to assist users with C4-C5 spinal injuries in holding objects with minimal effort. The design is lightweight, customizable, and optimized for 3D printing.

Materials & Printing Process

The prototype is being 3D printed using PLA filament for durability and strength. A small-scale 3D printer is used, ensuring cost-effectiveness and accessibility. The printing process involves layer-by-layer deposition with precise tolerances to maintain functionality.

Testing & Iterations

Post-printing, the prototype will be tested for:

- Grip efficiency (ease of holding various objects)

- Comfort & fit (ergonomic design validation)

- Durability & strength (load capacity testing)

Future Prospect(s)

QuadTool will evolve with ergonomic refinements, adjustable sizes, and modular designs. Future upgrades include motorized gripping, sensor-based control, and lightweight materials. Mass production and collaborations with healthcare will expand its reach, ensuring greater independence for users

Subject/Need(s)

The toothpaste roller was designed to assist individuals who have limited or no functionality in one hand. Traditional toothpaste tubes require two hands to squeeze out the paste effectively. This device allows users to operate it with a single hand, making personal hygiene tasks more accessible.

About need knowers

Name: Sobha Maya

Age: 38

Background: Master's in Sociology

Age: 38

Background: Master's in Sociology

Medical Condition

She experienced a physical disability due to a medical mistake. During the plastering process of her upper arm, a lack of proper blood flow led to severe complications, ultimately necessitating the amputation of her arm. This incident significantly impacted her ability to perform daily activities

Challenges Faced:

- Performing basic daily tasks independently.

- Significant difficulties during pregnancy and breastfeeding due to the absence of an upper limb.

- Emotional and psychological impact resulting from the disability.

Requirement:

She requires a prosthetic hand to regain independence in performing essential daily activities. A functional and well-designed assistive device could greatly improve her quality of life by enabling her to carry out tasks such as holding objects, caring for her child, and managing household chores.

Future Considerations:

- Collaboration with medical and engineering teams to develop a functional prosthetic hand.

- Exploring 3D printing and cost-effective solutions to make prosthetics accessible.

- Partnering with organizations specializing in assistive technology for further assistance.

Prototyping

- Conceptual Design

- Material Selection

- Manufacturing Process

- STL for body

- STL for shaft

- STL for holder

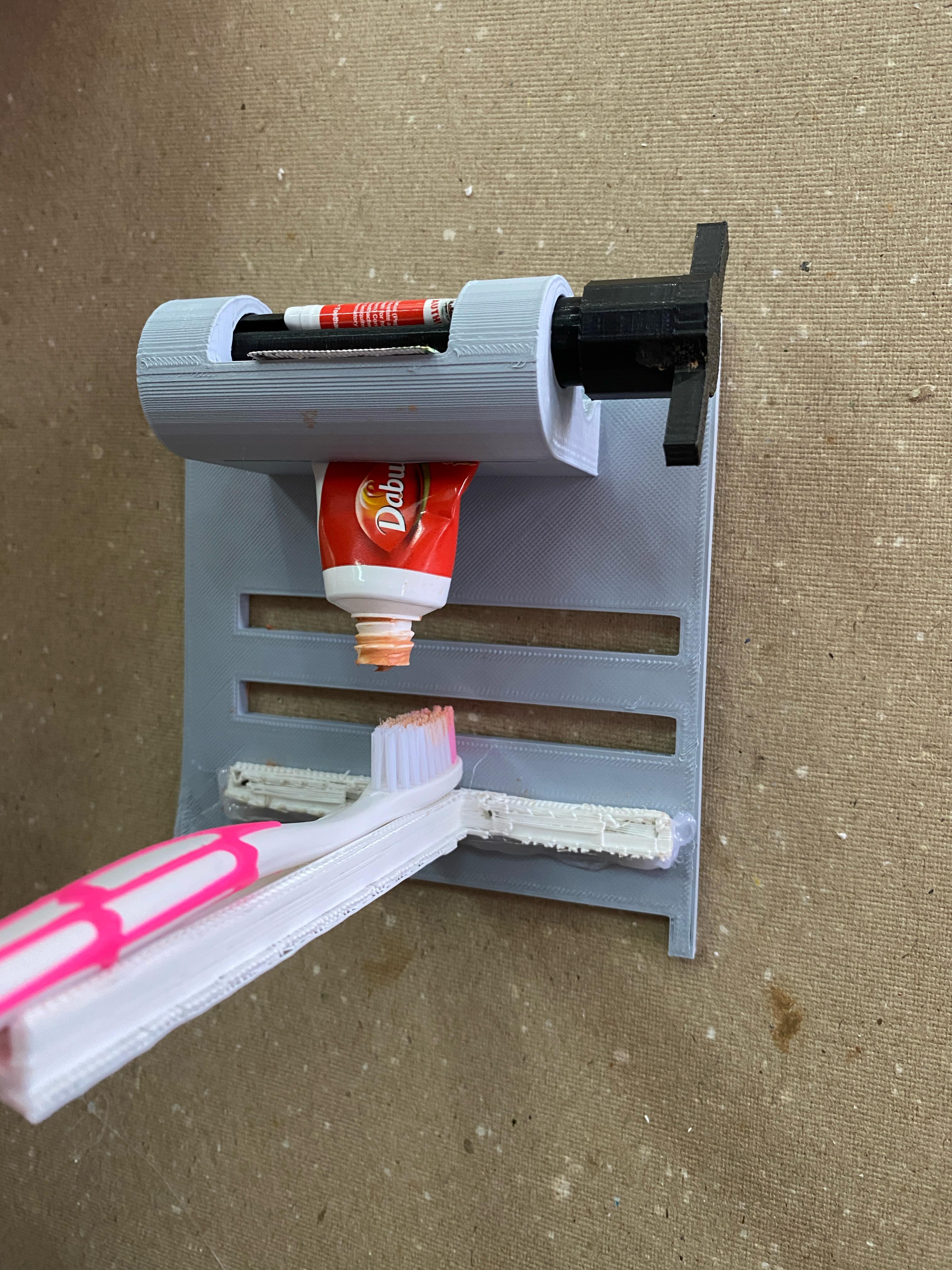

Conceptual Design

- Initial sketches and CAD models were created in SolidWorks to visualize the mechanism.

- Considerations were made for ergonomics and user-friendly operation.

Material Selection

- 3D printing materials such as PLA were used for prototyping due to their ease of fabrication and durability.

- A simple rotating handle and clamping mechanism were incorporated.

Manufacturing Process

- The first prototype was 3D printed and assembled.

- Adjustments were made based on testing, including improving the grip mechanism and roller efficiency.

ideas

- Create a simple yet effective mechanical design that allows easy rolling of the toothpaste tube.

- Ensure the design is compact and can be mounted or placed securely for stability during use.

- Utilize a rotating handle mechanism to control the dispensing of toothpaste efficiently.

Result(s)

The toothpaste roller effectively aids one-handed users by ensuring effortless tube squeezing and minimal waste. Its ergonomic design enhances usability, while testing confirmed improved accessibility and convenience. Users reported increased independence and ease of use.

Testing

result

About need knower

Name: Kanchha Gubhaju

Background: Bachelor's in Electronic Engineering

Interests: Automation

Strengths: Team Leading, Hardworking

Background: Bachelor's in Electronic Engineering

Interests: Automation

Strengths: Team Leading, Hardworking

Medical Condition

Kanchha Gubhaju suffered a severe burn injury that damaged his kneebone, leading to the underdevelopment of his leg. As a result, he relies on a prosthetic leg for mobility. However, due to the nature of his injury, he is unable to bend his knee, making basic daily tasks challenging.

Challenges Faced

- Limited Knee Flexibility: The prosthetic leg does not allow bending, restricting mobility.

- Difficulty in Performing Daily Tasks: Actions like climbing stairs, sitting comfortably, and walking on uneven terrain are difficult.

Possible Solution

- Hydraulic or Pneumatic Knee Joint: A smart joint mechanism that allows controlled bending when needed.

- Adjustable Locking System: Provides stability while walking and allows bending when sitting.

- Lightweight Material: Using carbon fiber or titanium to reduce weight while maintaining durability.

Current Status

He is unavailable, and there are constraints in resources to fully develop a tailored solution for his mobility needs. While efforts are being made to explore potential improvements, progress is limited due to these challenges. We apologize for the inconvenience caused by resource limitations.

Future Prospects

- Bionic Prosthetics: Neural connectivity for more natural movement.

- 3D-Printed Prosthetics: Cost-effective and highly personalized solutions.

- Machine Learning for Adaptability: AI-driven enhancements for improved movement.