1. About the Need Knower

Mr. S. Thileepan, 32, from Kalmunai, suffered a high-voltage electric shock, damaging his flexor tendons and median nerve. After 13 surgeries, he lost fine motor control. As a kovil secretary, he wanted to resign, but they urged him to stay. He trained to sign but found it slow and painful.

Thileepan's Family

Anatomy

This needknower's trapezoid bone not moving properly.

Physiology

Diagnosis

His primary diagnosis is a high-voltage electric shock burn with deep tendon injury, exposing and crushing the tendons.

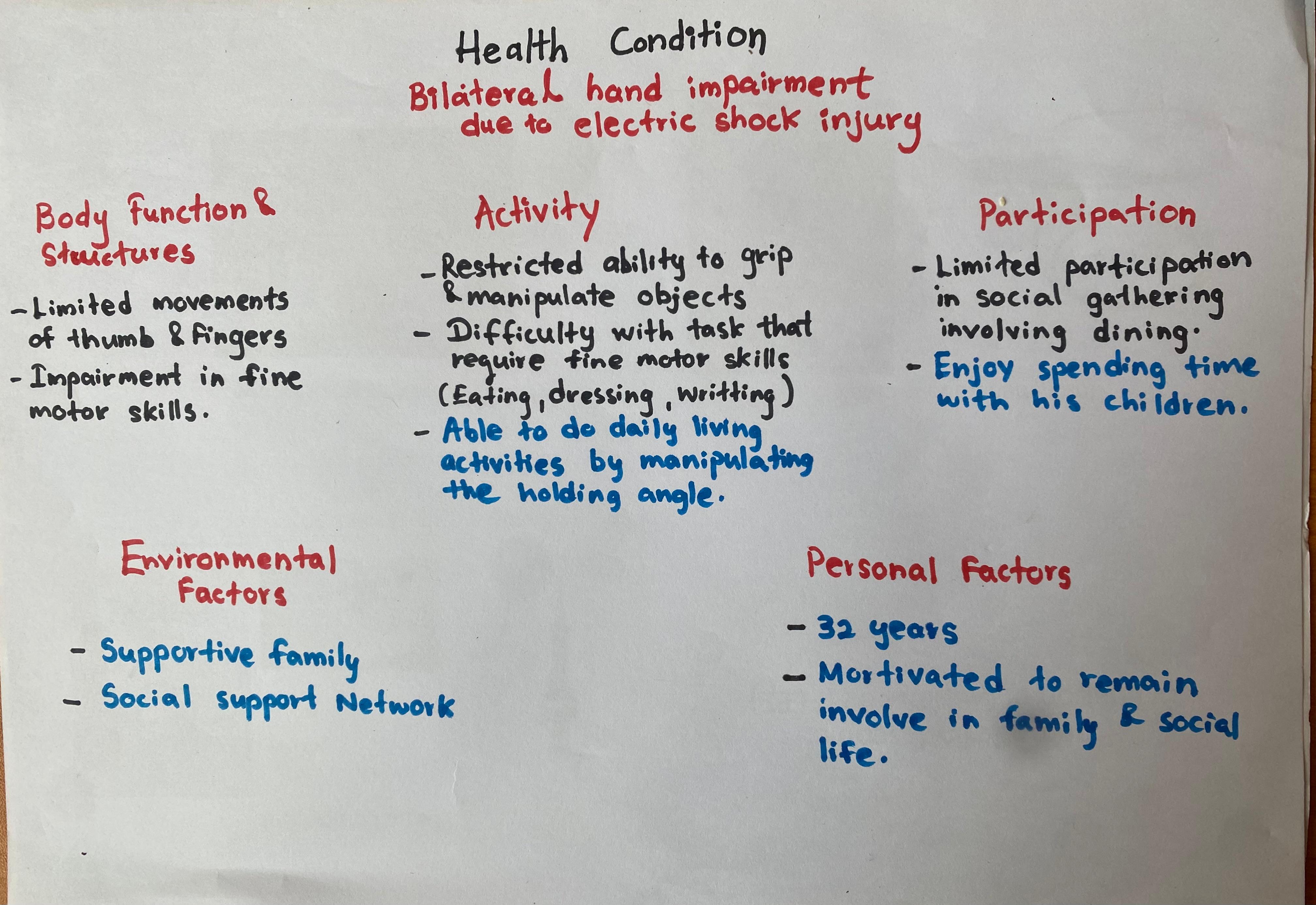

Condition: Bilateral impaired fine motor skills due to damaged flexor tendons and median nerve dysfunction

How we Identified his needs

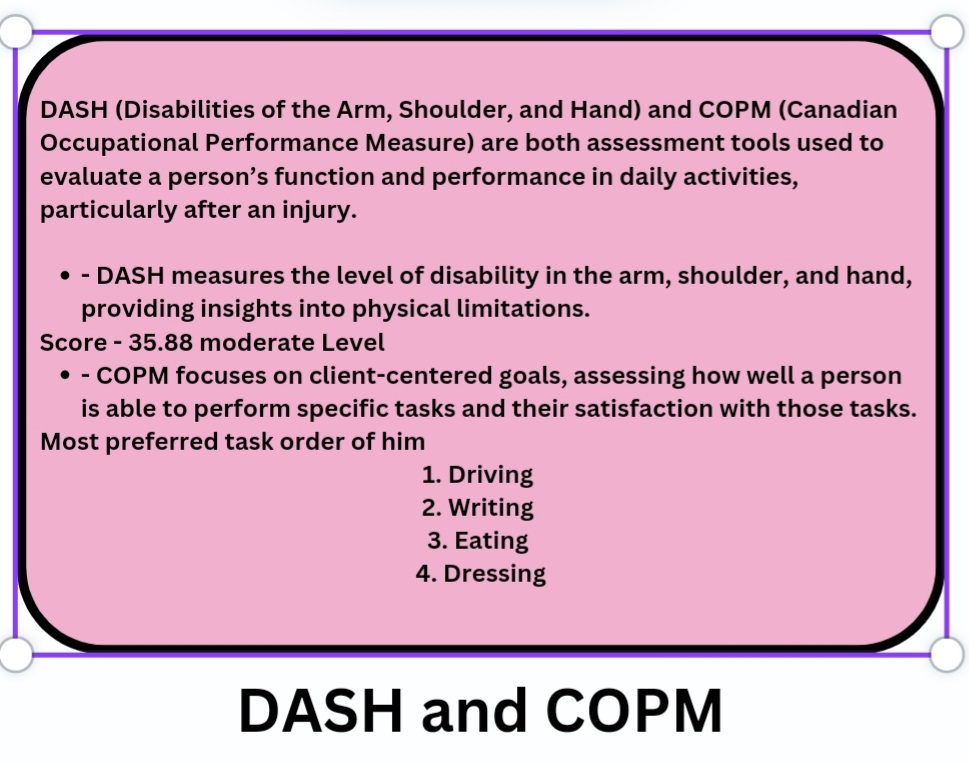

- Conducted assessments (ICF model, DASH, and COPM) to identify strengths and needs.

- Interviewed the Need-knower using formal and informal patient based questionnaires.

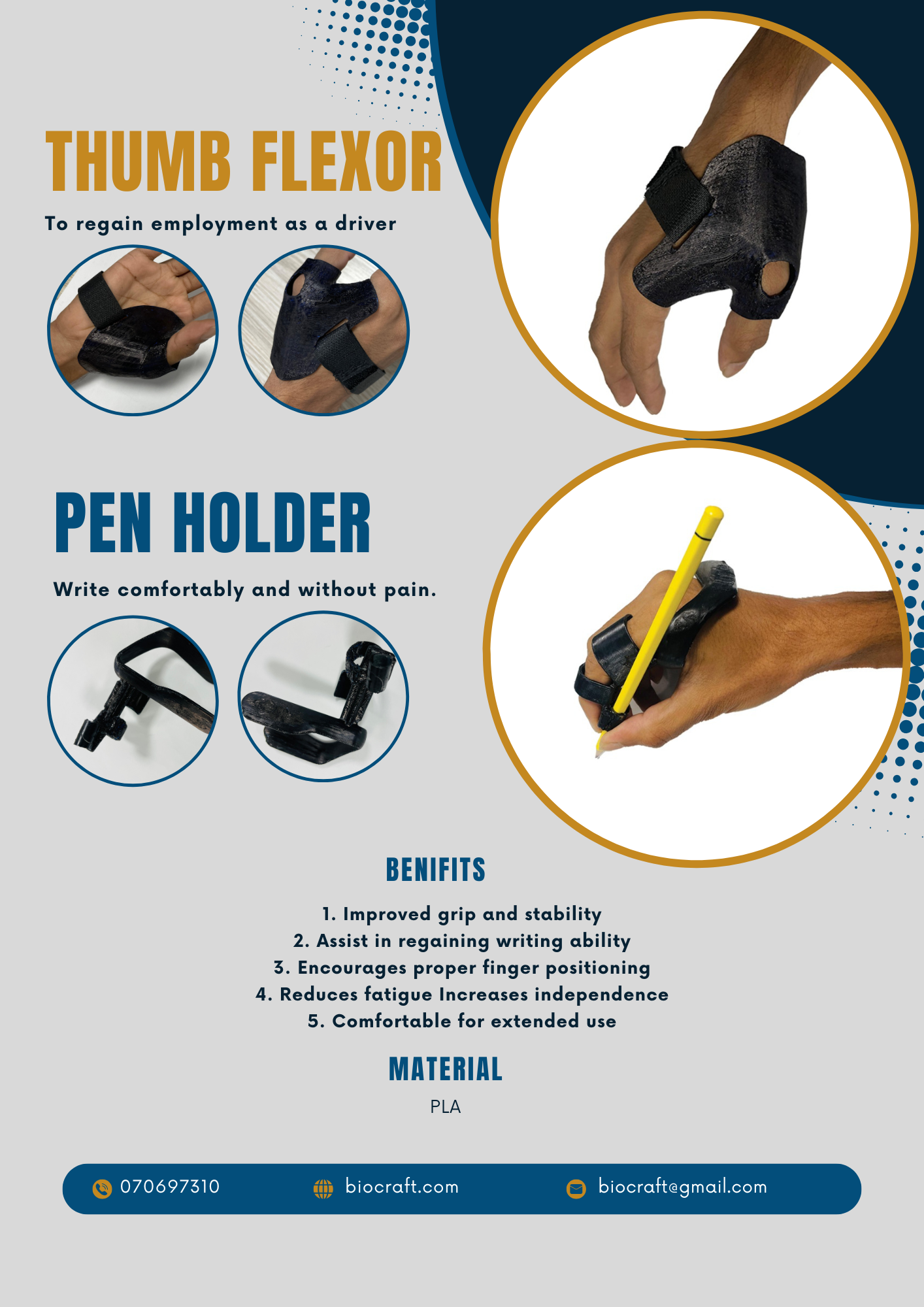

2. Subject / Need(s)

Mr. Thileepan faces two major challenges:

- Writing difficulties (Difficult and Painful)

- Employment barriers ( non employed after the injury)

Damage to hand

Strategies that we used to develop a device

- improved grip and stability

- Encourages proper finger positioning

- Reduces fatigue

- Increases independence

- Comfortable for extended use

3. Ideas

✔ Low-cost for easy accessibility

✔ No electronics, eliminating battery/recharge issues

✔ Lightweight for comfortable long-term use

Demo - Paper Prototypes

We created these prototypes using paper and tapes. We need to identify the correct angles and the shape of the device. This prototype was very helpful for us to develop the 3D Model

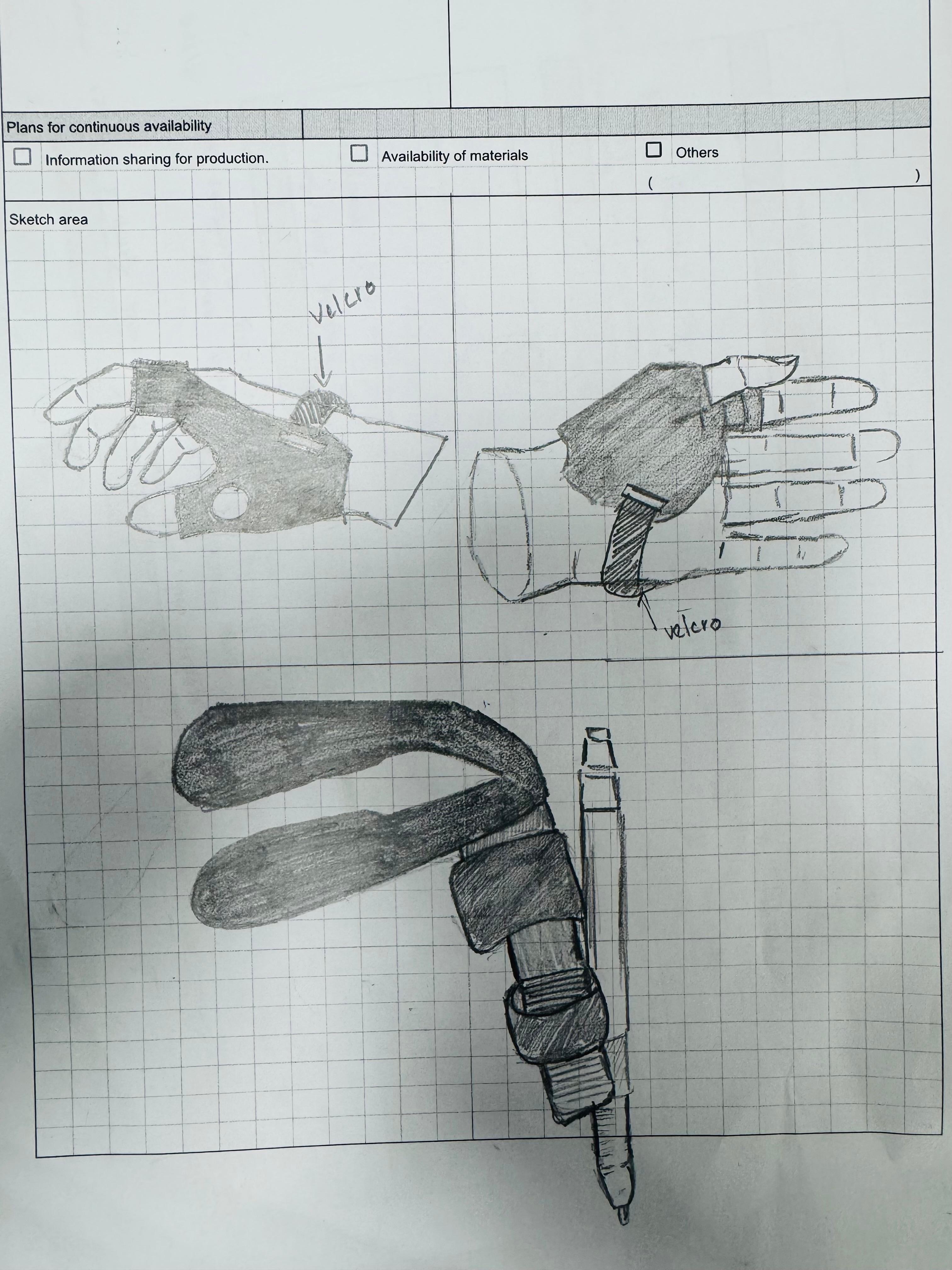

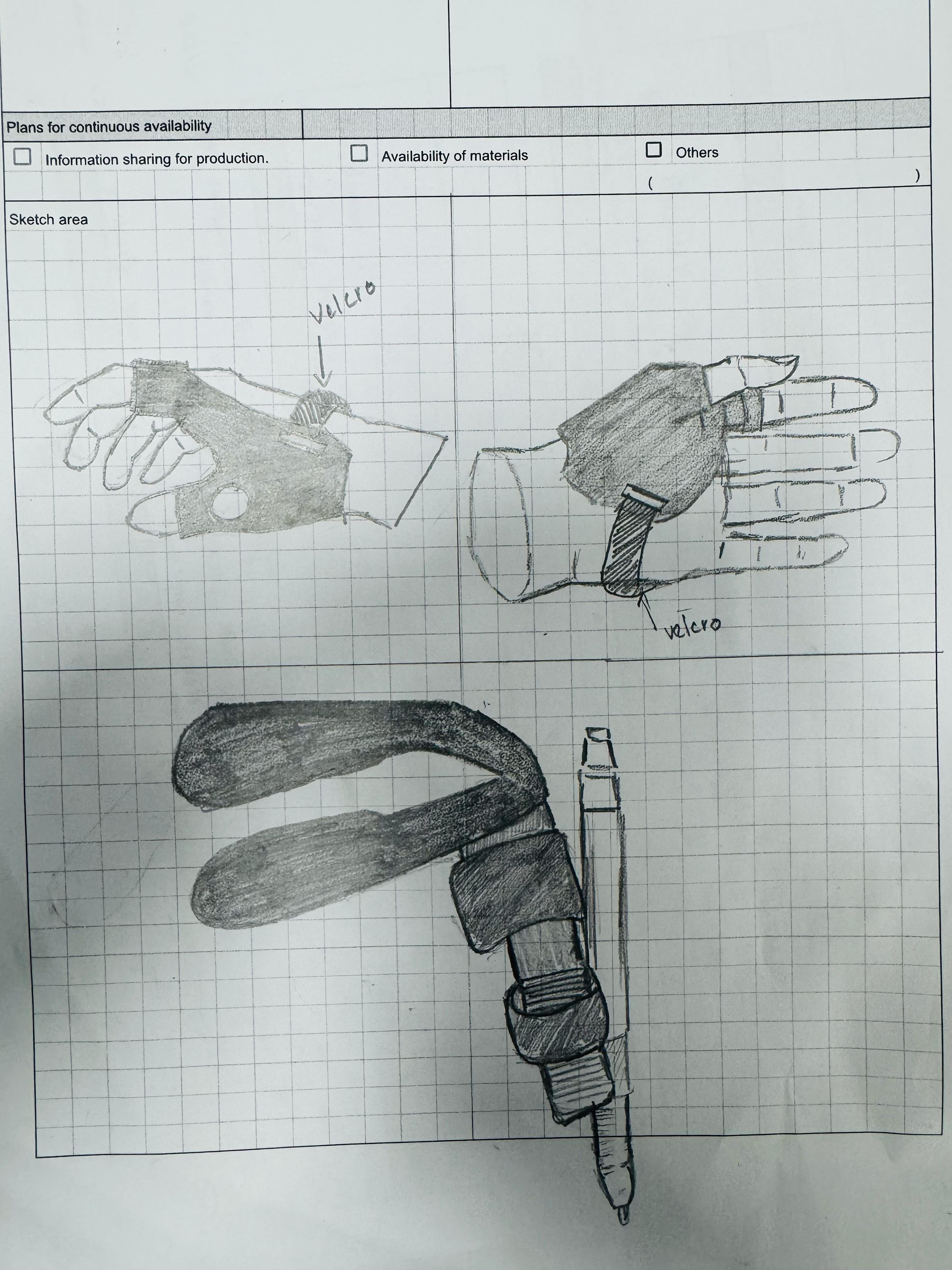

Sketches

Design Process of the Pen Holder Device

- Researched various assistive writing tools using online resources

- Discussed and analyzed the neeknower’s needs and challenges

- Created an initial concept based on functional requirements

- Sketched the pen holder design, focusing on comfort, grip, and ease of use

Protype

This was our first 3D-printed prototype. The PLA material was uncomfortable for the neeknower, but it helped us refine the final design. Based on this prototype, we added a support ring and adjusted the angle of the pen-holding clip for better ergonomics and usability.

Last Print with a different PLU material

With the help of the experts, we could print our prototype again, with modified ideas and more comfortably to the need knower using a different material of PLU

Final Product

As requested by the needknower, we color the device using black paint, and again modified the device changing the pen hold clip angle and adding 1 more supportive ring, we finalized the product

Material- PLU

Finalized model

5. 2nd Prototyping

✅ Adjusted grip structure based on Thileepan’s flexor tendon movements.

✅ Final tests showed 4× faster writing speed with no pain.

✅ Developed an early version of the Driving Assister for future testing.

Driving Assistive Device Prototype

This is the very first sketch that we drew to map our model

- Created an initial pencil sketch to visualize the basic structure.

- Designed the device with a rigid form for durability and support.

- Incorporated an MCP joint hole for flexibility and ease of movement.

- Ensured comfort and quick wearability, especially for driving.

Prototype

We created a prototype using paper and tape to form a simple, temporary model of the device. This allowed us to quickly test the shape, size, and fit, and make necessary adjustments to the design before proceeding with more permanent materials and 3D printing.

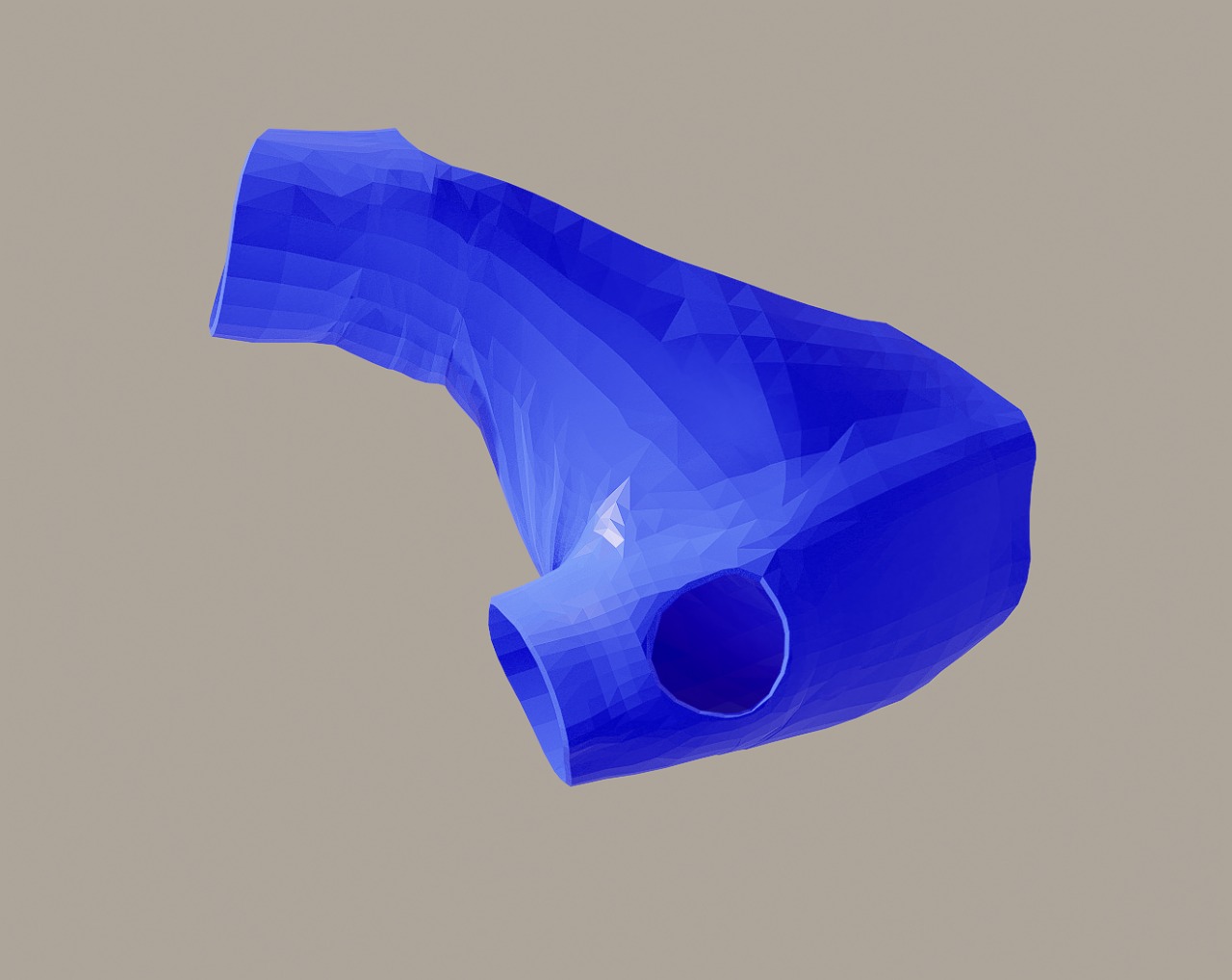

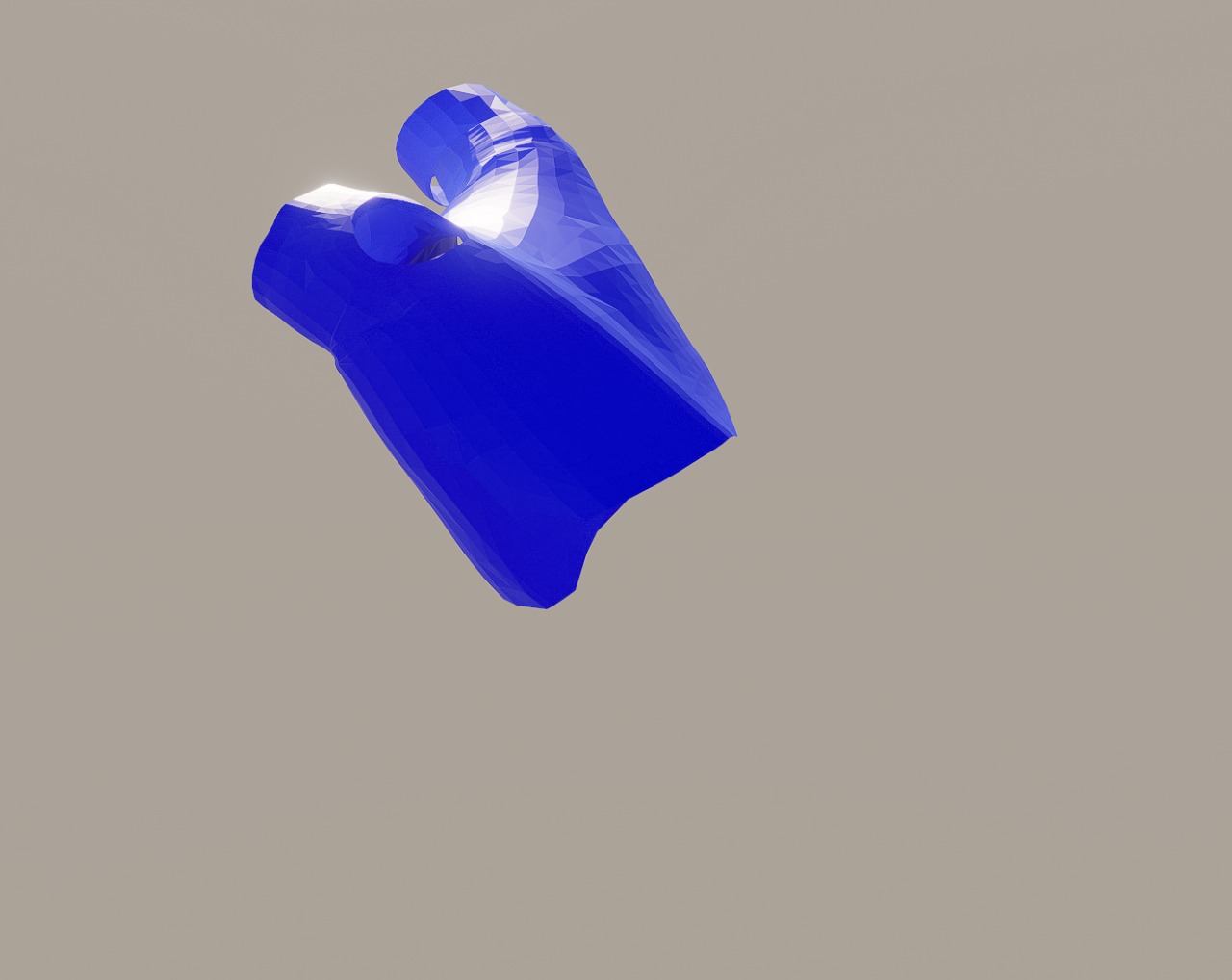

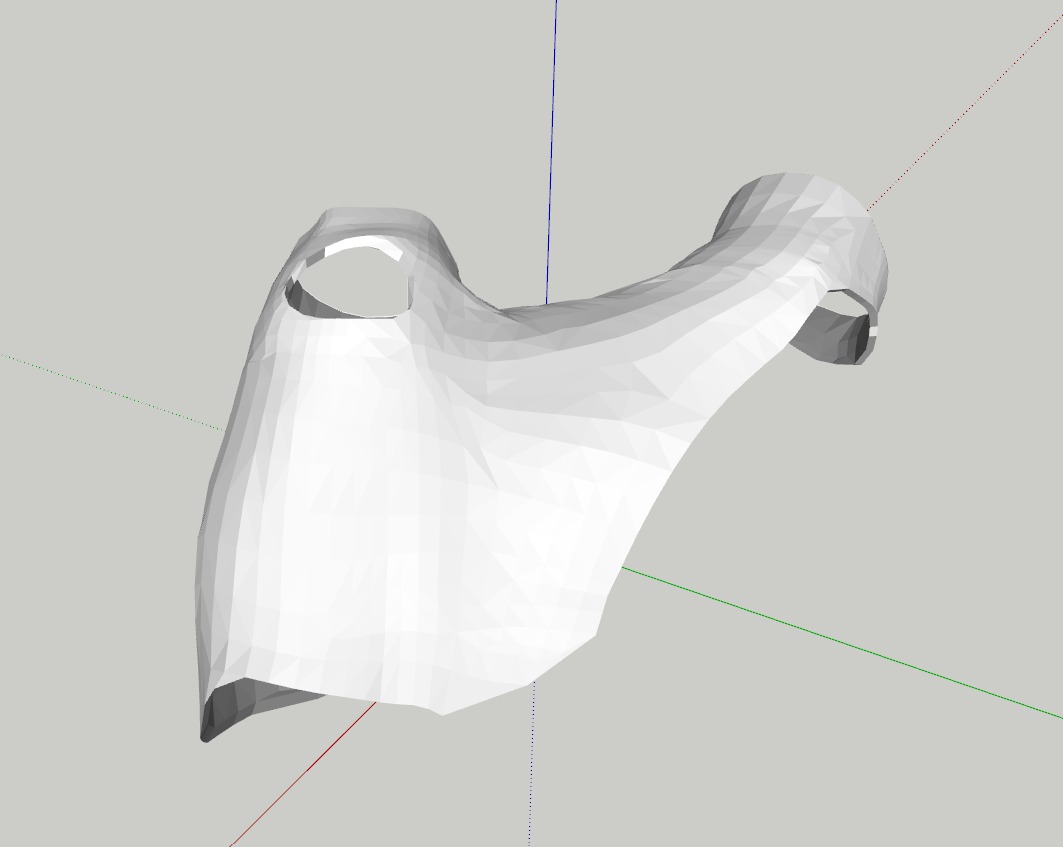

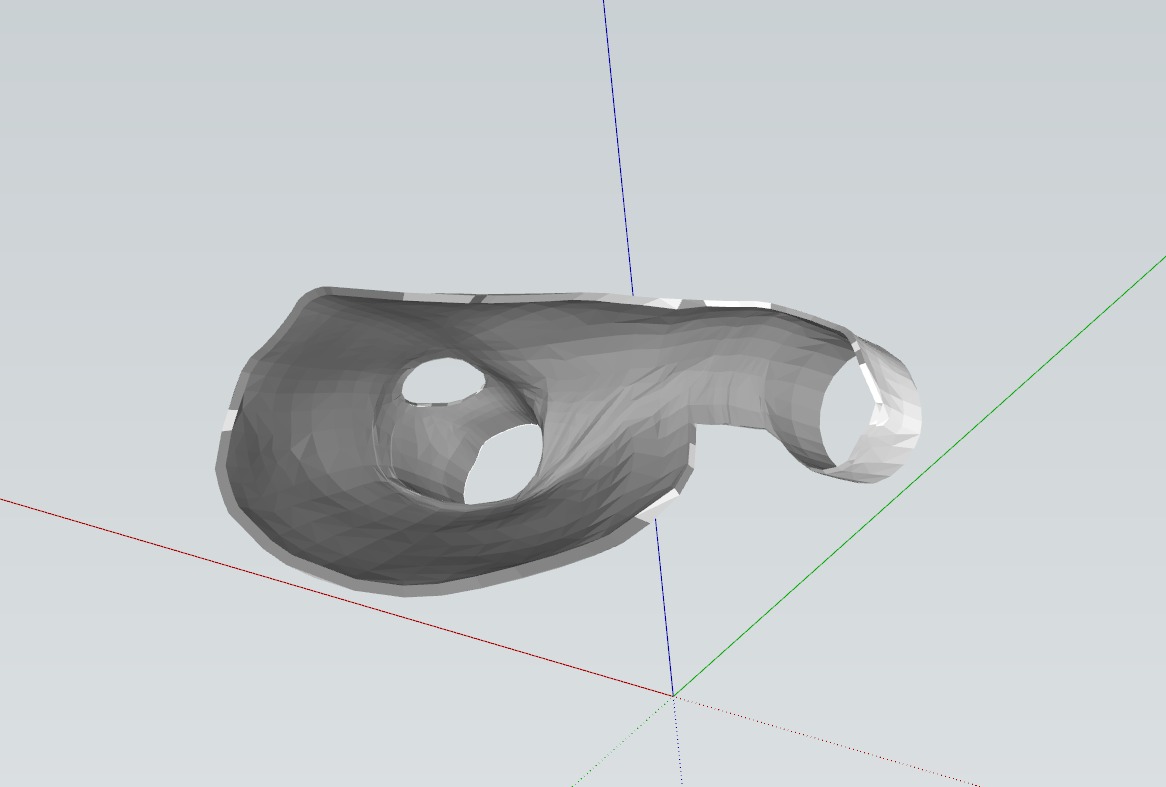

3D Model

This is our first 3D model. We planned and took precise measurements to position the thumb in the optimal angle, ensuring the device would provide the necessary support and functionality for the neeknower’s needs.

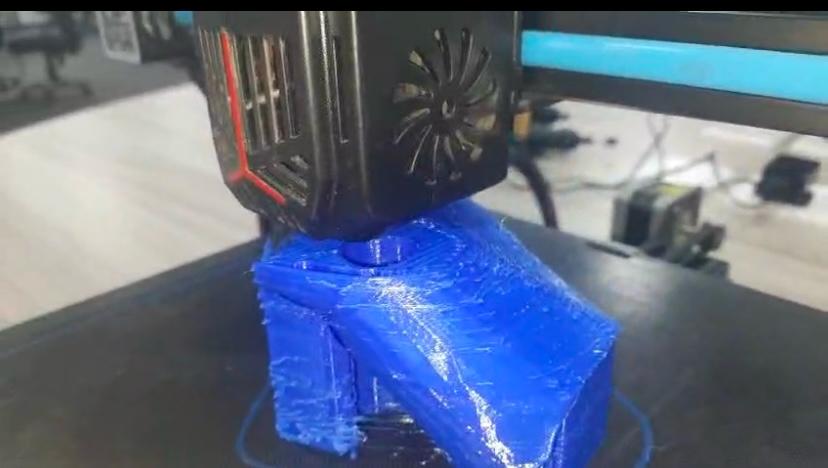

Printed Device

It took 8 hours to print this model, which required numerous supports due to its complexity. Designed for a human hand with customized measurements, it was a challenging model to create and print. Afterward, it took an additional 5 hours to remove the supports and clean the device.

* PLU material

* PLU material

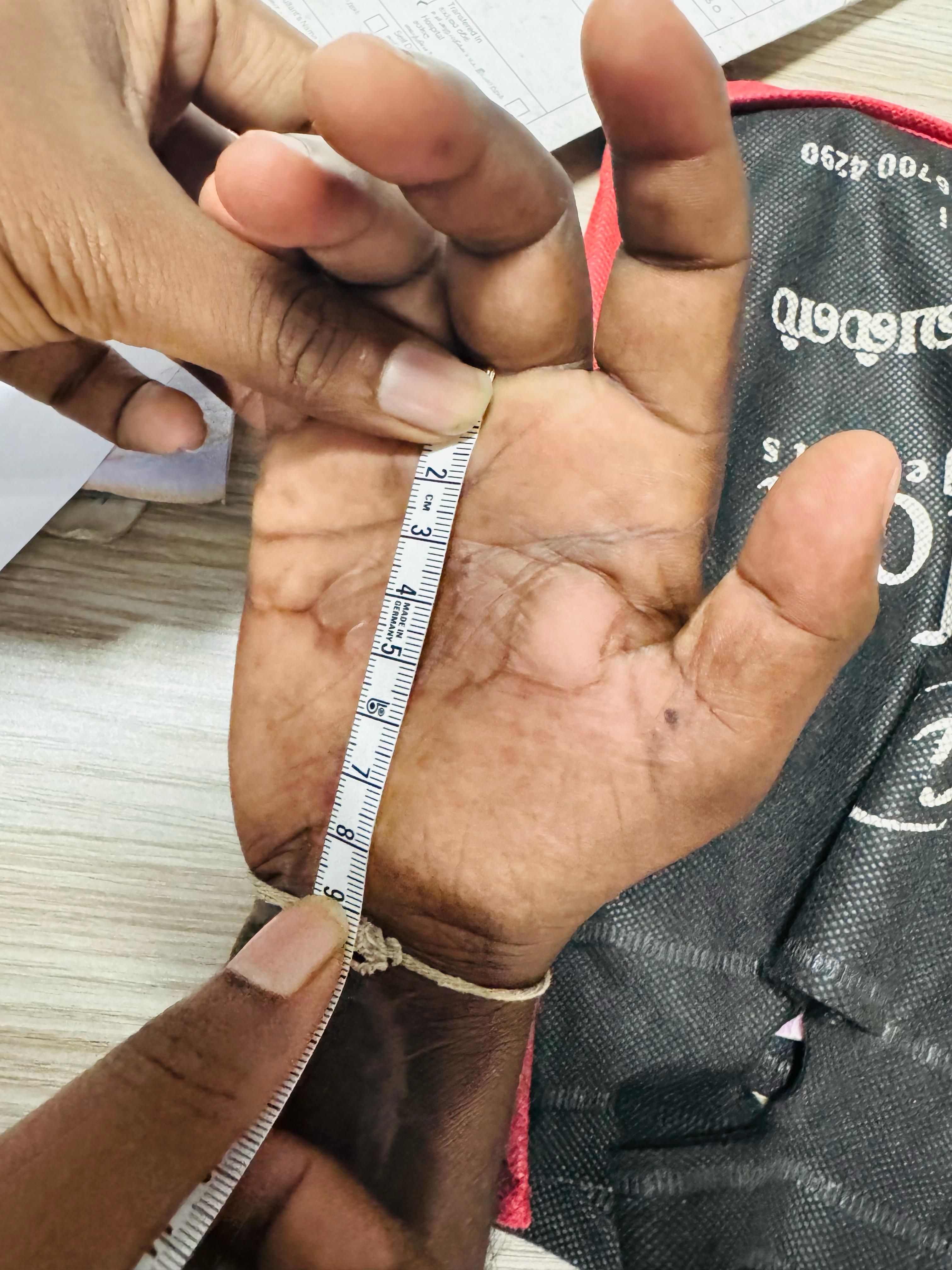

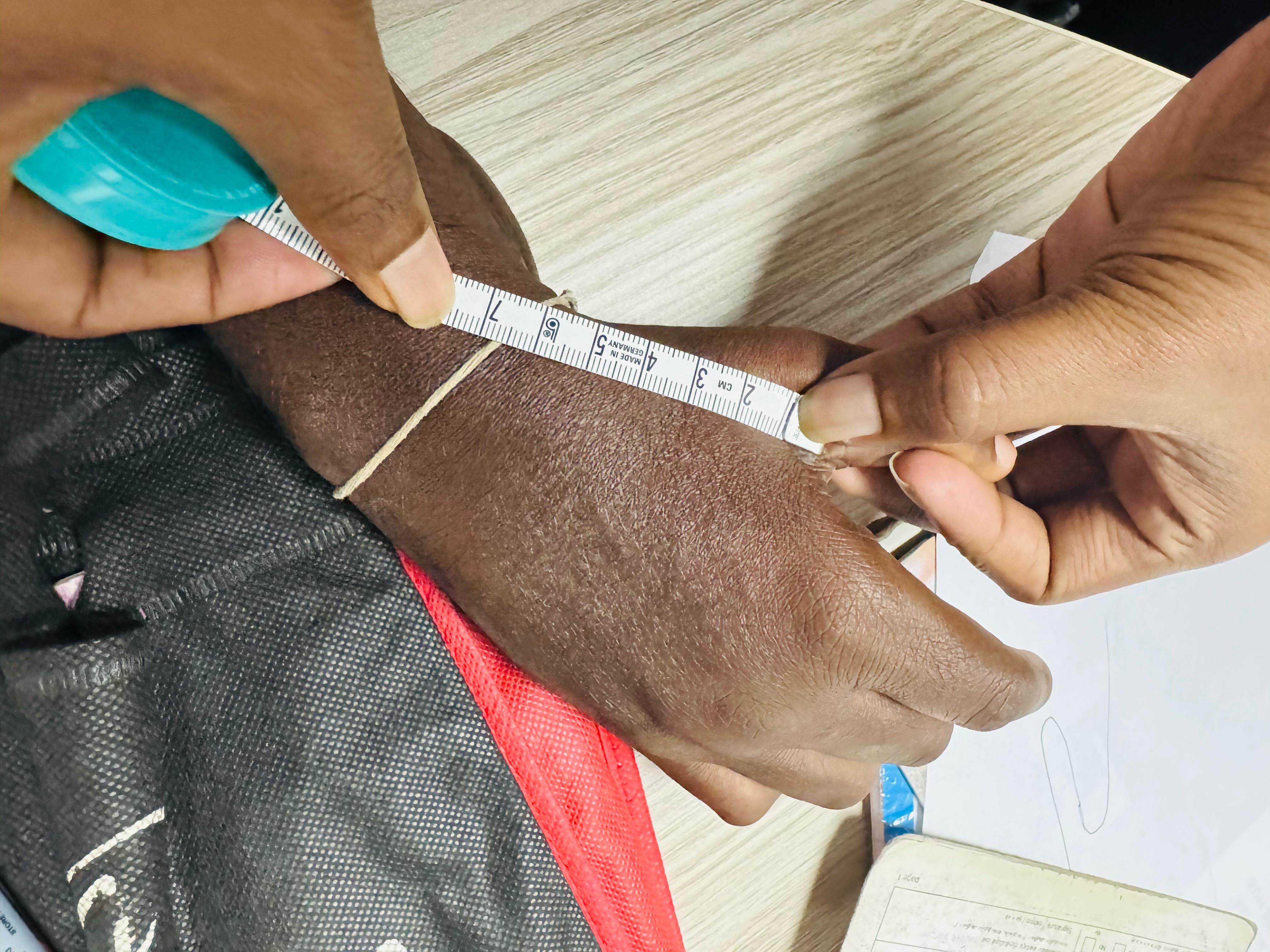

Measurements

We took measurements for both hands, but initially, we printed a device for the right hand to test its functionality. Once we confirm that the design works as expected, our plan is to create two customized devices—one for each hand.

Modified Device

After cleaning the device, we gave it to our need knower. However, we identified that the thumb bend was not sufficient for him to fully bring his fingertips together. To address this, we decided to modify the design and incorporated Velcro for a more adjustable fit in the new version.

Modification

- Cut the ring around the index finger to improve fit.

- Drilled two sides of the device for Velcro attachment.

- Used Velcro as a belt to secure the device, bending it toward the palm.

- Modified the design with available materials instead of printing a new angled version.

Final Product

* Finalized the product coloring it need knower's favorite color.

Need Knower Feedback

- Neeknower wore the device and reported increased comfort while driving.

- He can now feel improved finger grip and control.

- The device allows him to grab small items using his thumb and index fingertips.

- He gained a new skill, enhancing his daily functionality.

Driving Assister 3D Model

7. Future Prospects

🔹 Expand the project to help others with similar hand impairments.

🔹 Add more customization to fit different user needs.

🔹 Collaborate with medical experts & rehab centers for better development & distribution.

We all enjoyed every second of this project

Challenges

01. Less experiences

1. This was the first 3D printing experience for all six team members

2.Five members had never seen a 3D printing machine before

4.Only one team member could create the 3D printing model

02. Less Resources

1.On the second day, we lost our designer due to an emergency, preventing us from modifying the design. However, the rest of the team worked together to adjust the devices using other tools and materials.

2.Our usual presenter couldn’t attend to final day due to an internship program

Strengths

1.The "need knower" is not just a client, but part of our family.He was enthusiastic about the competition and supported us, staying up late into the night

3.We used various tools and materials to shape the final product according to the patient's needs.

BIO CRAFT Team

The Need Knower Ratings for Before and After designs

Before - 9/10

After - 10/10

Our Main goals

- Make it as affordable as possible (Minimal Manufacturing Cost)

- No Electronic parts (rechargeable issues)

- As light as possible