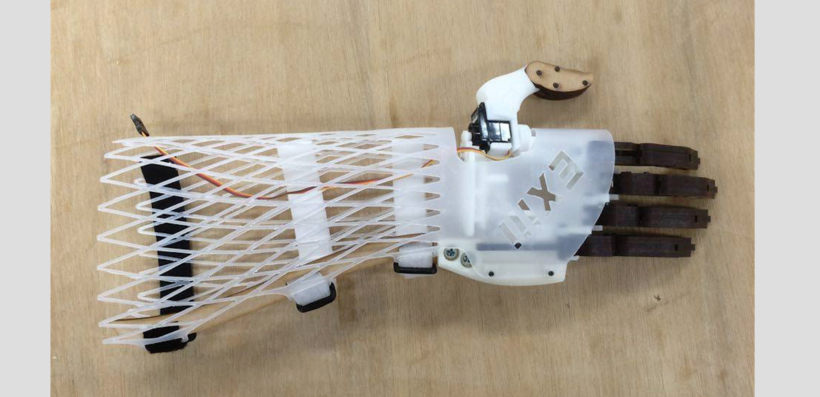

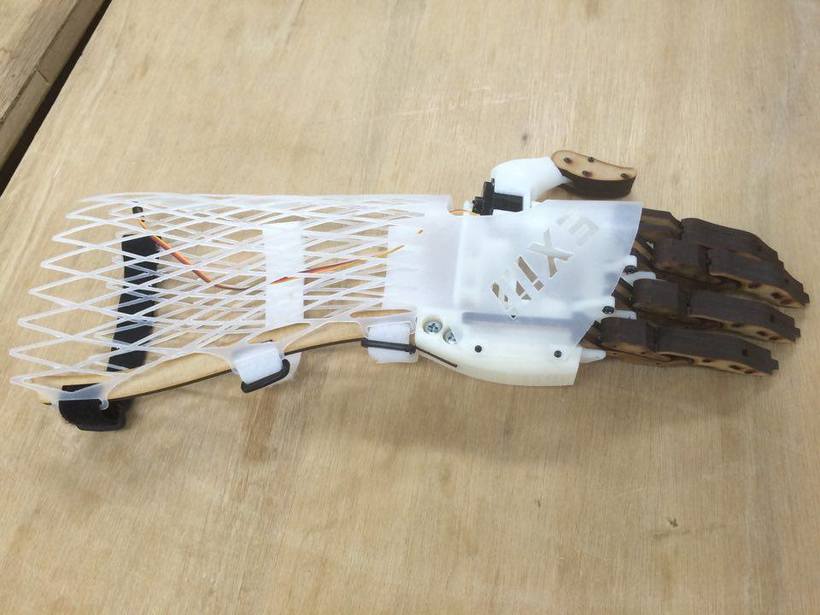

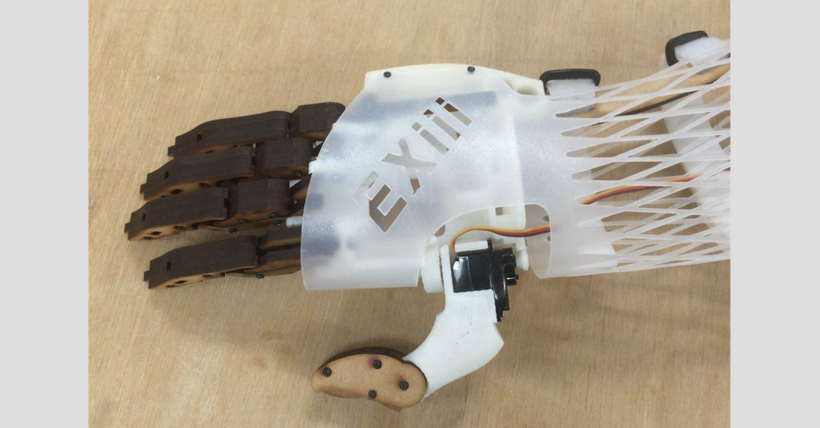

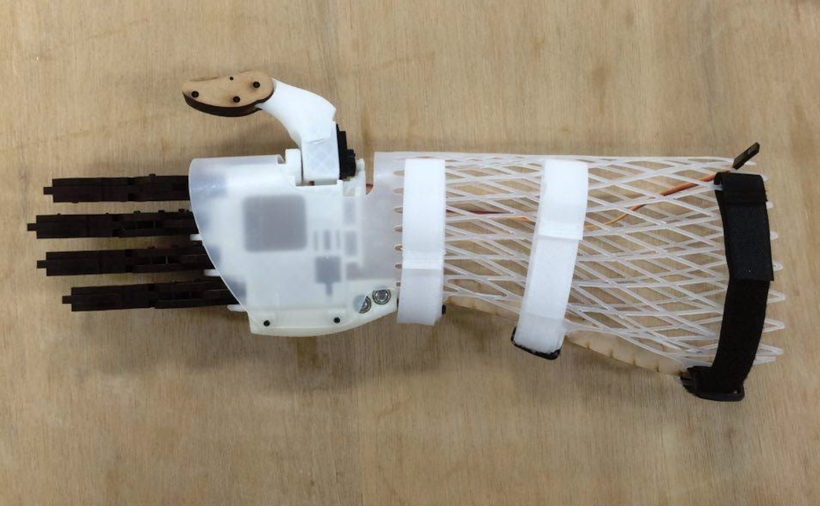

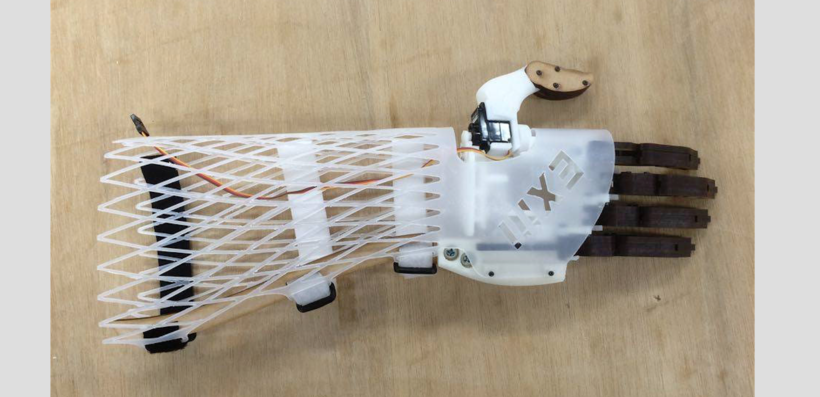

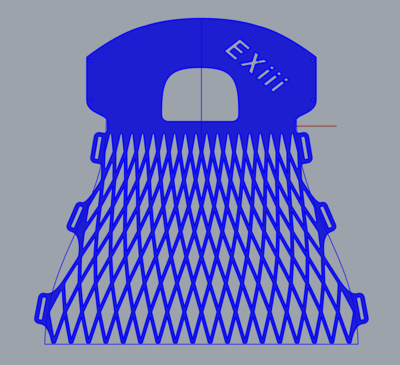

This prosthesis limb is a low-cost design which is inspired by the Hackberry of Exiii company (

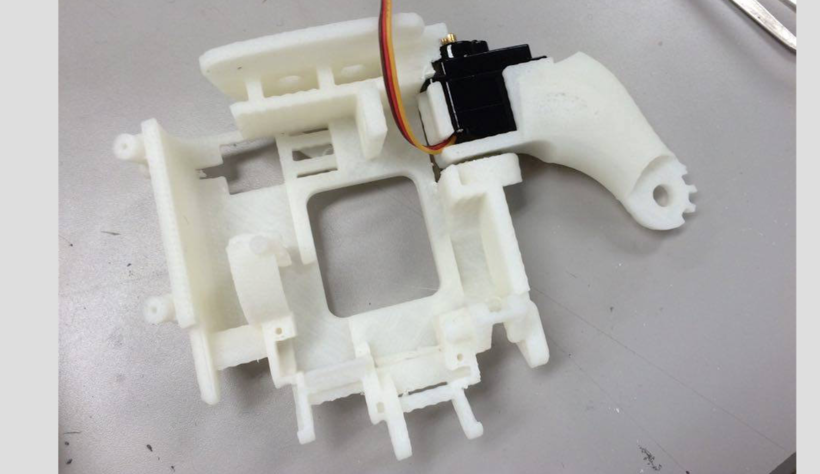

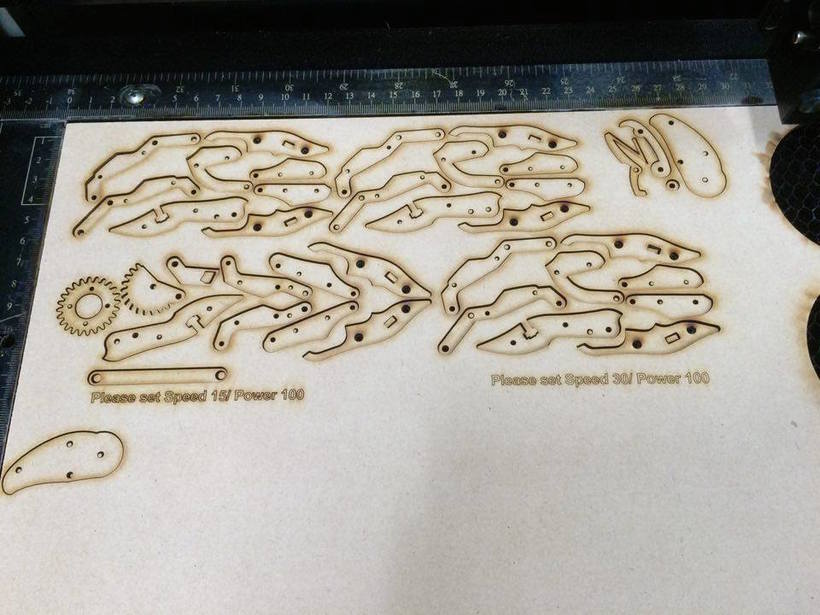

http://exiii-hackberry.com). Hackberry is already in a very low cost and simple technical requirement that compares to most of electronic prothetic on the internet, but a Up Plus 2 printer is recommended for building all necessary 3D printed parts. Even UP is a handy machine, but printing all parts take about 30 hours as I know, or longer. So that's why I tried to replace printed parts by laser-cutter piece as possible in this project. I redesigned the palm and thumb, and other fingers and arm are made by laser cutter. The making of these fingers and arm only spent about 30 mins(not include assembly), and redesigned palm only require 2 hours to be printed. I hope this project can help those people who want to make Hackberry but doesn't have time or UP printer. Last, appreciate the Mr. Yamaura and other members of Exiii provided kind assistance during this work!

Comments