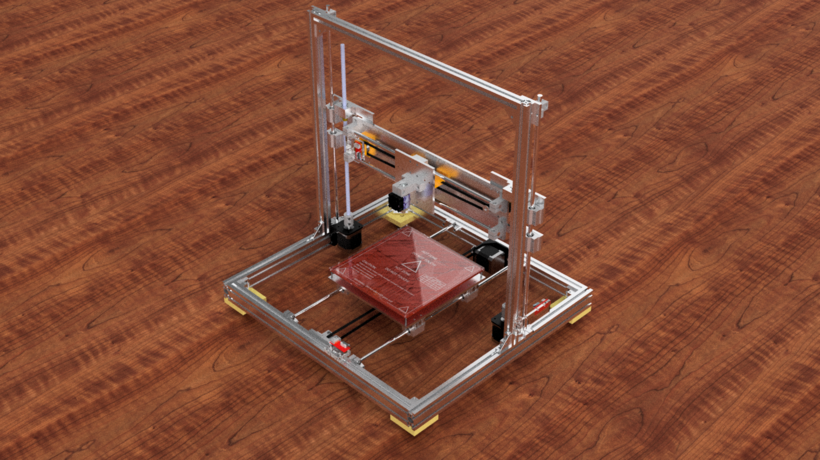

First I designed Base frame of my own 3d printer.

CAD is Fusion360.

Materials as following...

SF-20・40 SF9-242 500mm

D Bracket SS w/screw-tap SFJ-017

ST Nut SS(M5) SFN-TX5

Adjuster M8×21mm clear

Claw nut M8

MDF 6mm

CAD is Fusion360.

Materials as following...

SF-20・40 SF9-242 500mm

D Bracket SS w/screw-tap SFJ-017

ST Nut SS(M5) SFN-TX5

Adjuster M8×21mm clear

Claw nut M8

MDF 6mm

Comments