making CNC router

Owner & Collaborators

License

Summary

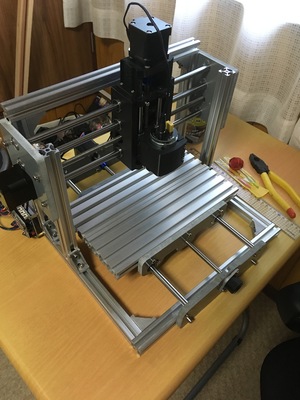

Making a CNC2417 kit.

Assembling and control the CNC by GCode sender(now selecting).

Now planning Linking the CNC to Internet( IoT) By Raspberry pi. Details will be attached later soon..

Now planning Linking the CNC to Internet( IoT) By Raspberry pi. Details will be attached later soon..

Materials

Tools

Blueprints

Making

- Download .zip file and extruct grbl folder into arduino's libraries folderhttps://github.com/1wise/grblv1.1-laseraxehttps://youtuber.byte.jp/pc/1211But this update makes Grbl conntroller obsolete.

- I finally chose bCNC as Gcode Sender to operate CNC2417 on raspberry pi.Reference as following...https://github.com/vlachoudis/bCNChttps://cnc-selfbuild.blogspot.com/2017/01/bcnc.html

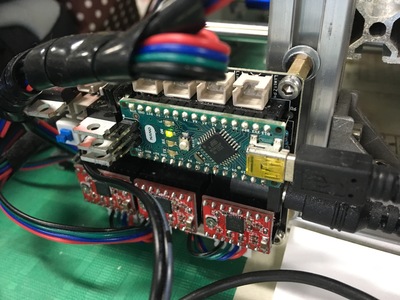

- For stabilization of communication with PC, I updated CNC2417's CPU for genuine arduino nano.Grbl platform is grblv1.1-laseraxe as same.

- Endmills for cutting material.All has 3.175mm shank diameter.

References

Usages

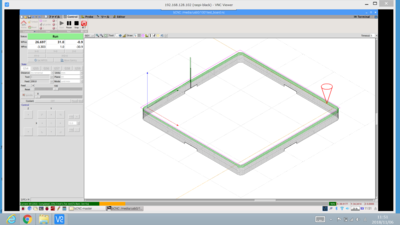

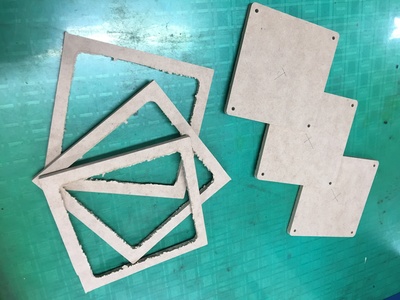

Cutting 120x120 MDF plate for barrel polishing machine

Cutting MDF plate by CNC2417 w/bCNC(On Raspberry pi)

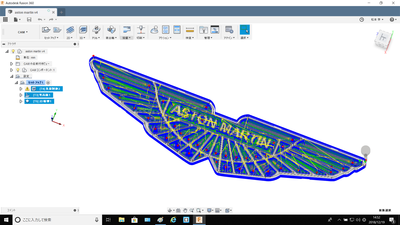

Cutting aston martin logo

Cutting acrylic aston martin logo by CNC2417 w/bCNC(On Raspberry pi) Toolpasses is made by Fusion360 CAM function. First try was defective because of outline toolpass speed setting. The speed was too high so End mill became to hot during outline cutting.

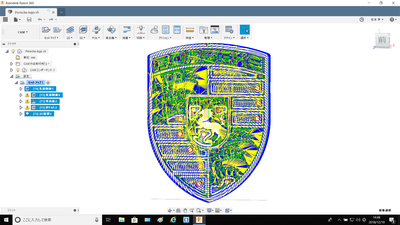

Cutting porsche logo

Cutting acrylic porsche logo by CNC2417 w/bCNC(On Raspberry pi). Toolpass is made by Fusion360 CAM function.

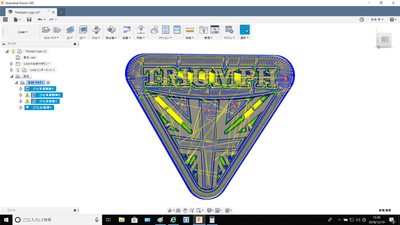

Cutting triumph logo

Cutting vinyl chloride triumph logo by CNC2417 w/bCNC(On Raspberry pi) Toolpasses is made by Fusion360 CAM function.

Project comments

- It would help if you gave more attention to the bold things and Ashram Escort Service is a so-called amazing aspect for men.

- Take your sexual pleasure and fantasy to the next level with the young hot girls of Hotel ITC Maurya Delhi Escorts .

- You have a talent for wu wear making complex ideas easy to understand.

- The level of professionalism from independent Ashok Nagar Escorts Service is impressive, offering companionship that feels both intimate and genuine.

Comments