DAY 1

First, under the direction of our technical adviser Karma Wangda sir, we went to Super Fablab to familiarise ourselves with 3D printing. We learned the fundamentals of the printer and the filament.

Second, in order to learn more about the need and the issue our need knower, Mr. Jari Lal Gurung, is dealing with, we went to his car. and after that, we were motivated and aware of the issue he was dealing with. His thumb and fingers tighten, making it difficult for him to change gears. His expectation was If he can get any device to help him support his thumb and fingers while driving.

Second, in order to learn more about the need and the issue our need knower, Mr. Jari Lal Gurung, is dealing with, we went to his car. and after that, we were motivated and aware of the issue he was dealing with. His thumb and fingers tighten, making it difficult for him to change gears. His expectation was If he can get any device to help him support his thumb and fingers while driving.

Most importantly, we took him for a five-kilometer test drive during which we assessed his ability to shift gears and allowed him to park, allowing us to truly experience his suffering and learn more about the issue.

thirdly, since we knew more about his problem we proceed on with the brainstorming session where we came up with different ideas.

The Design Plan

Phase 1:

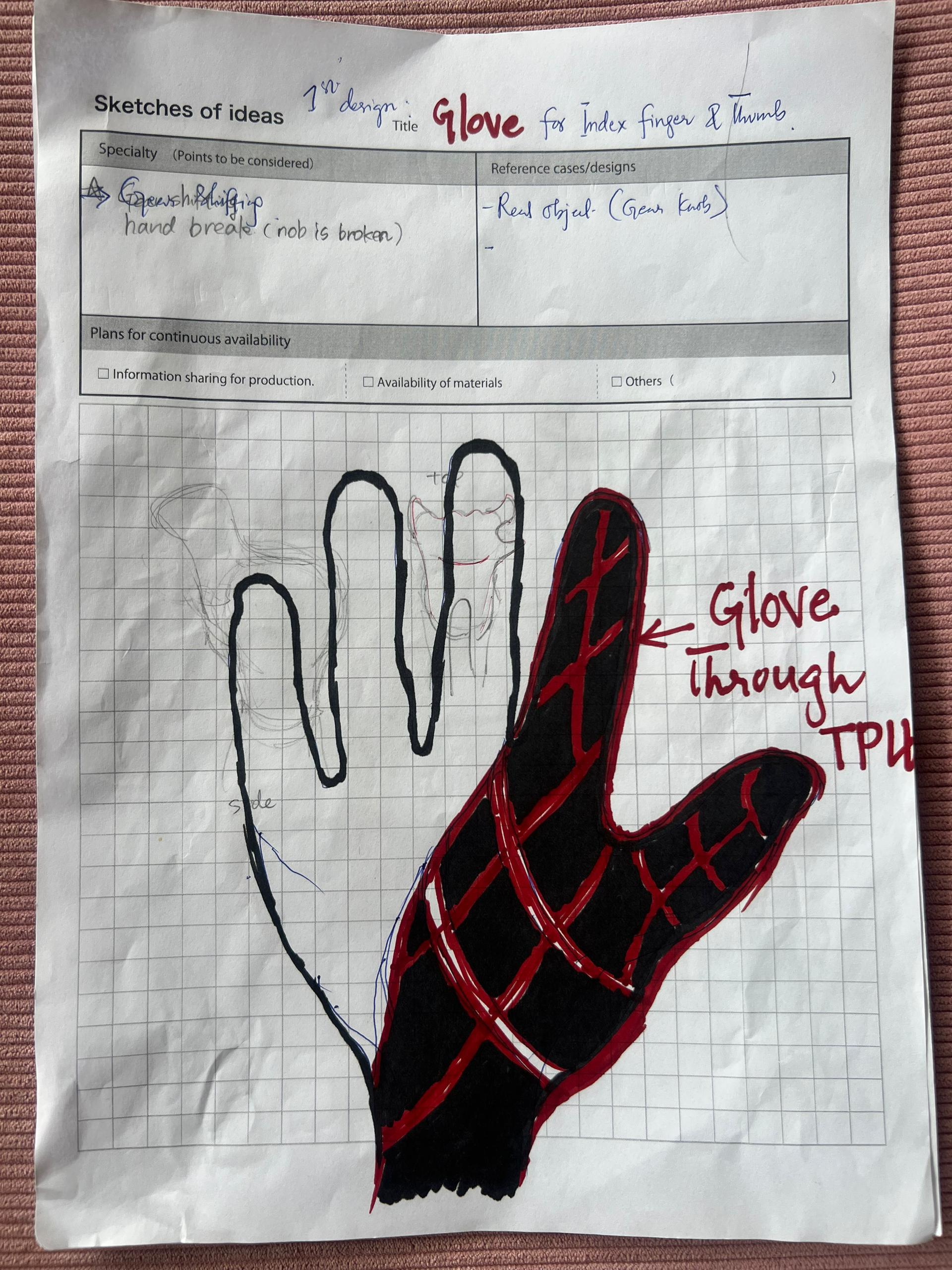

The plan was to make gloves for his thumb and index finger. This design’s objective is to make it easy for him to move his index finger and thumb.

However, the plan couldn't proceed because, in the long run, his thumb and index finger would be stiff. This could result again to be difficult to move.

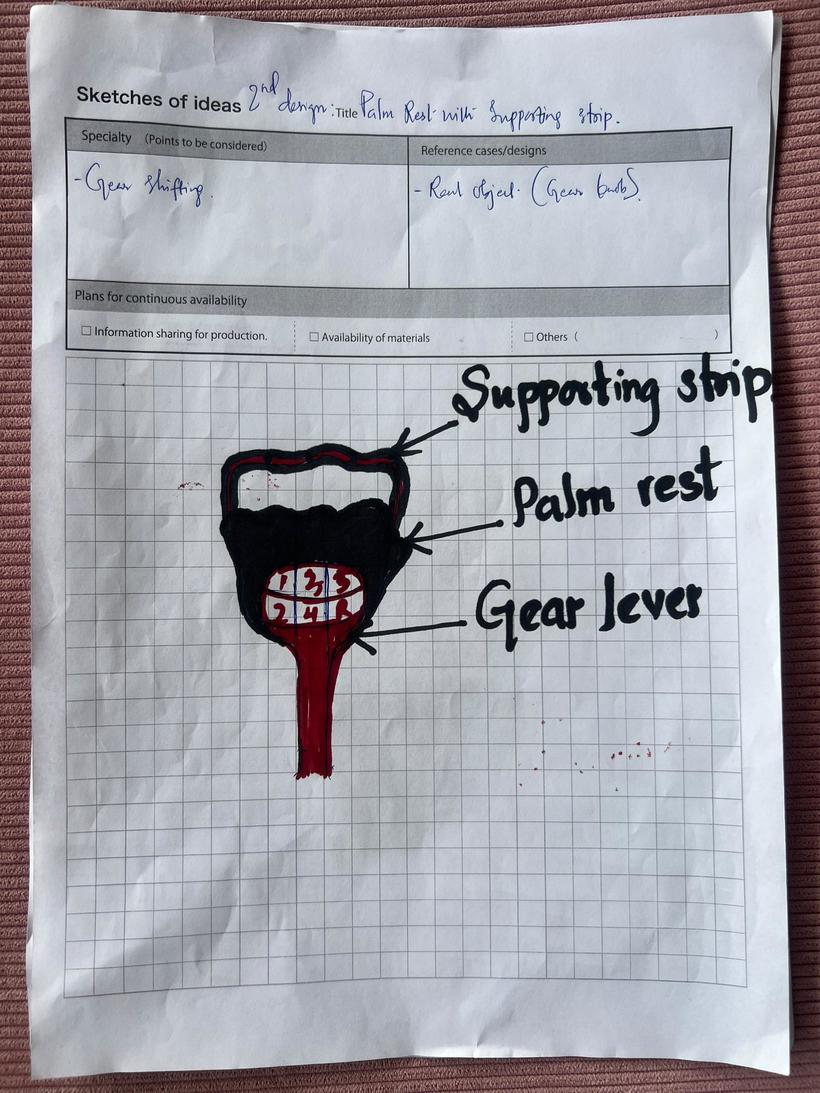

Phase 2:

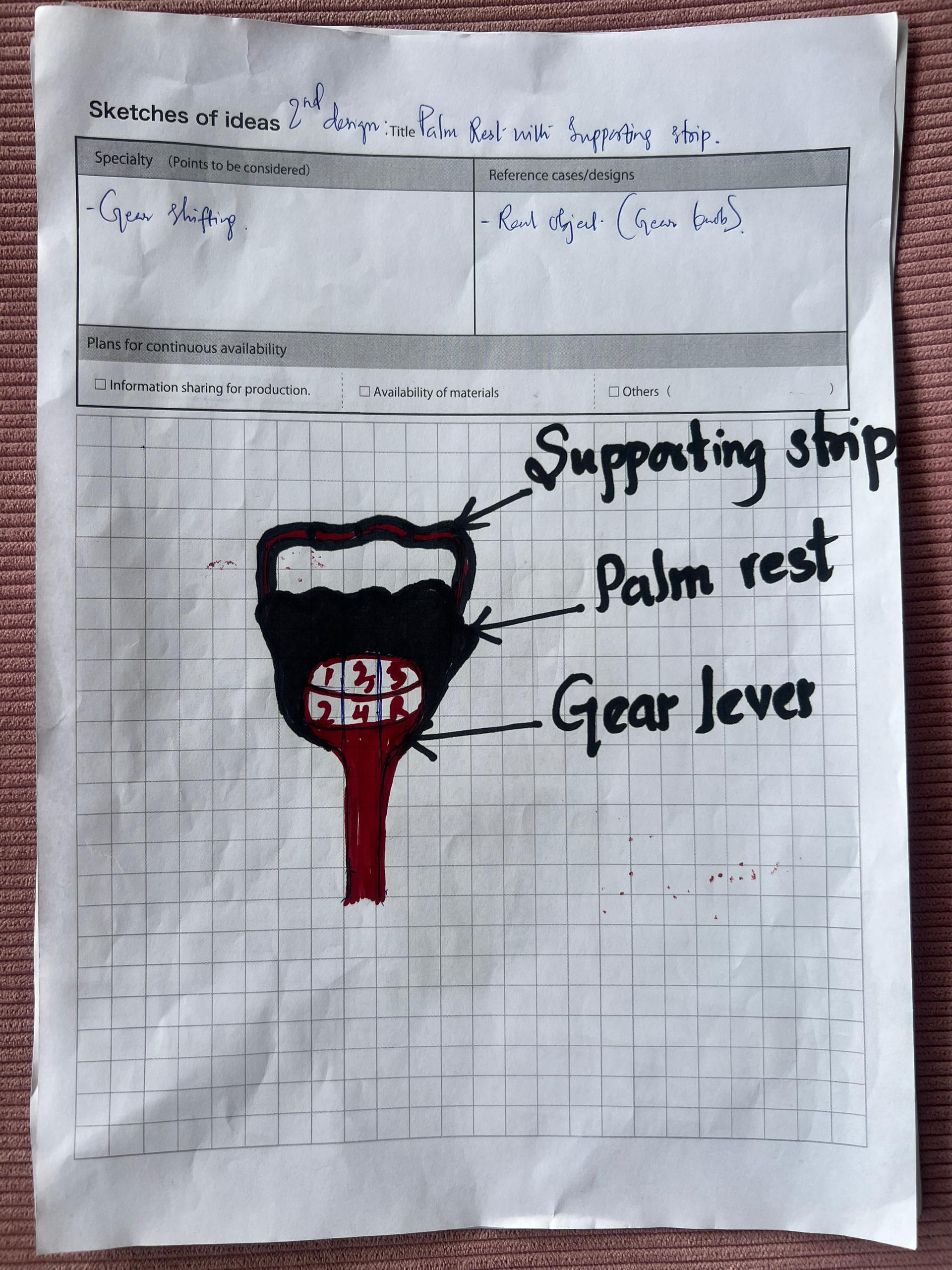

The phase 2 plan was to create a top knob on top of the gear knob with the palm resting on the top and a supporting strip on top to hold the hand. The result of the plan was to make it easier for him to shift the gears while driving. Clay was used to make the first design of the prototype.

However, the plan could not proceed further because it was inconvenient for him to shift the gear, and also in case of emergency, the supporting strip on top to hold the hand of the prototype can be difficult for him to take out of the palm rest holder immediately.

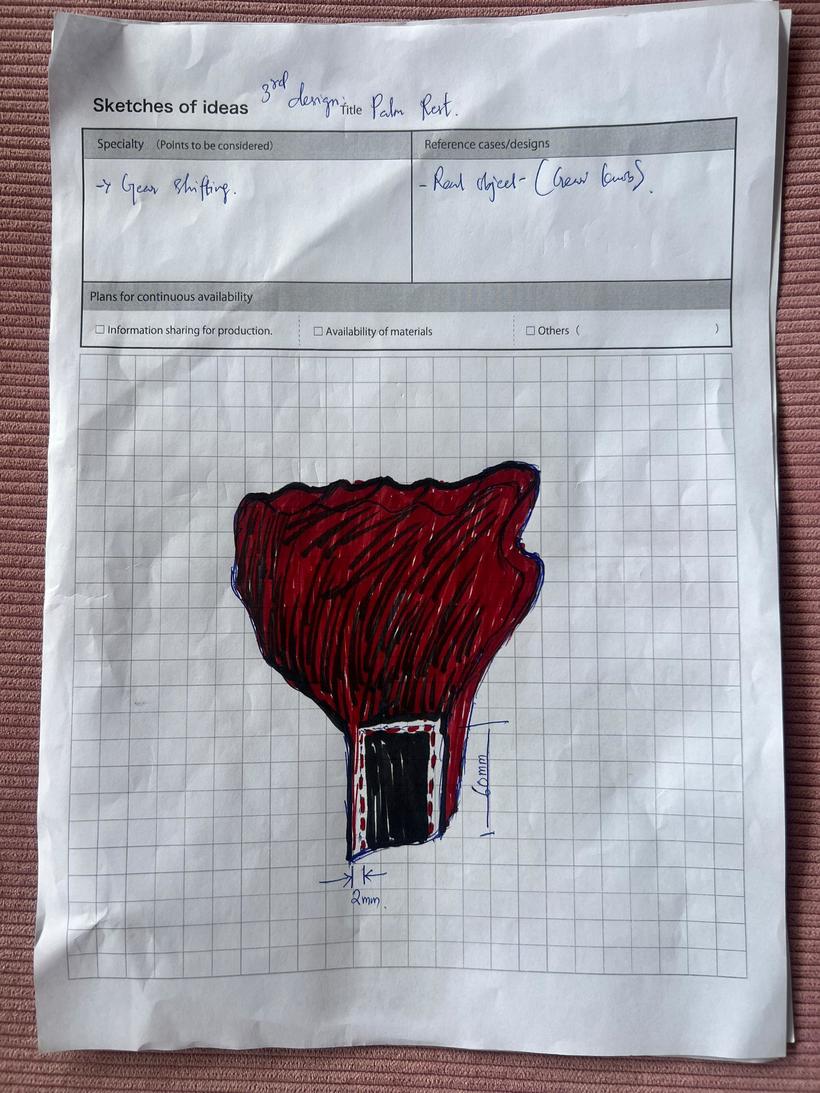

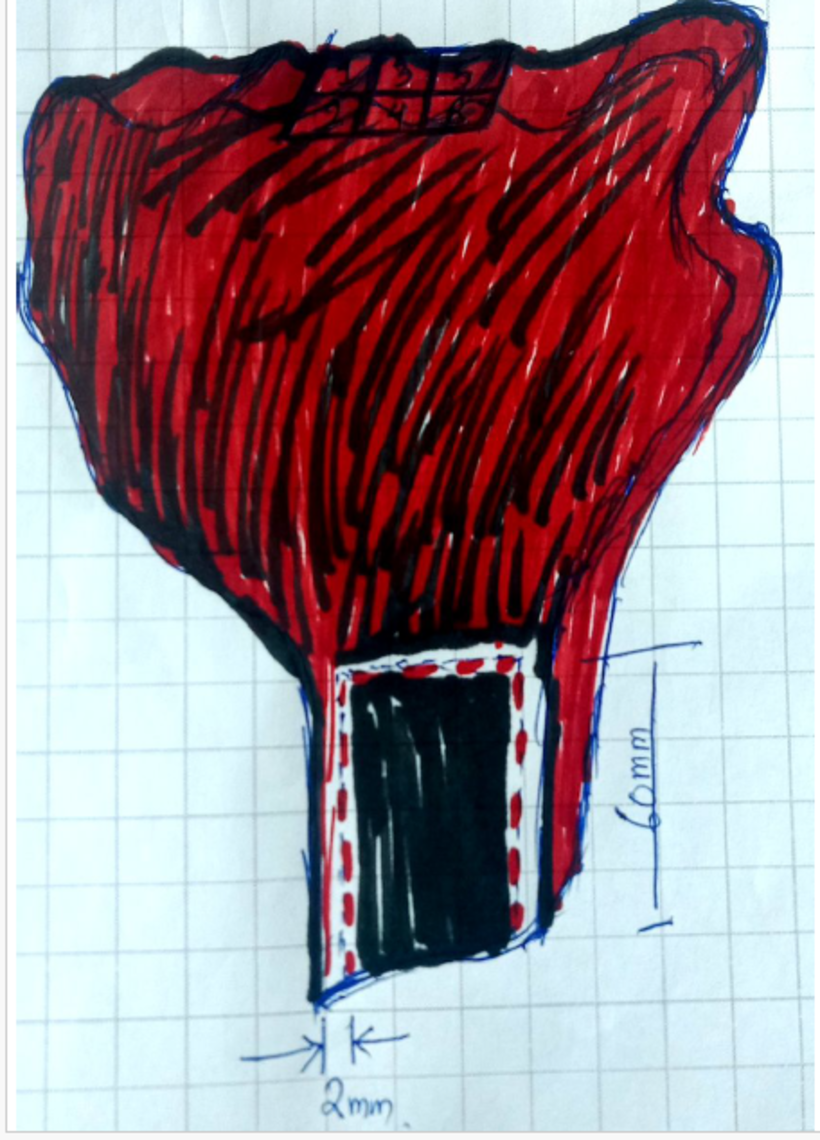

Phase 3:

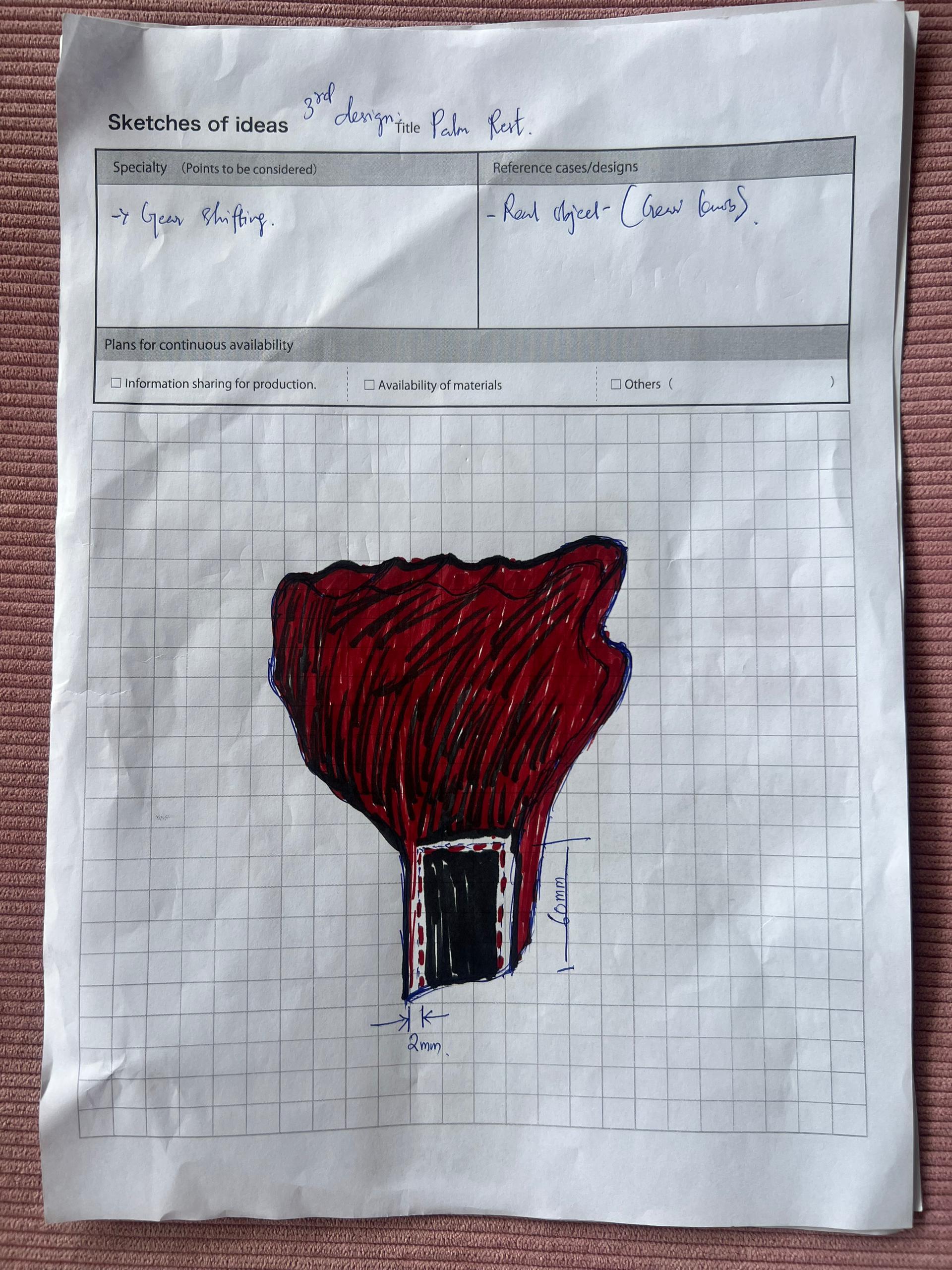

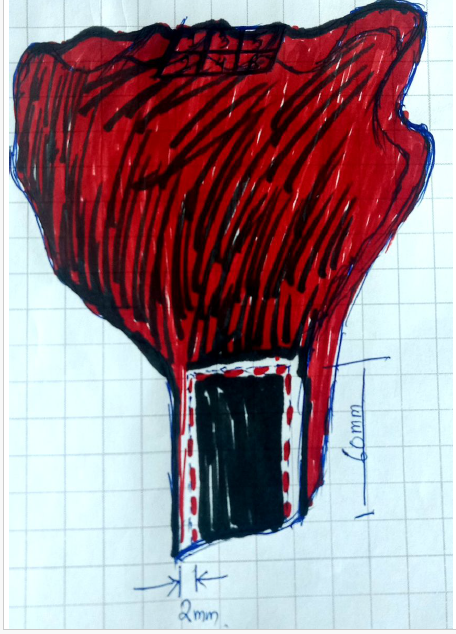

The third or final phase was creating a top knob on top of the gear knob with the palm resting on the top. The supporting strip of the prototype was removed so that it can be easier for him to hold and remove his hand from the gear knob easily. In addition to the plan, we thought of attaching the knob directly to the gear lever for easy functionality and durability. This became the final plan for the product and we proceeded on with the prototype.

The prototype was first made using clay and tested out with Mr. Gurung. After Mr. Gurung’s final approval, based on comfortability, we 3d scanned the prototype. The design was then 3d printed.