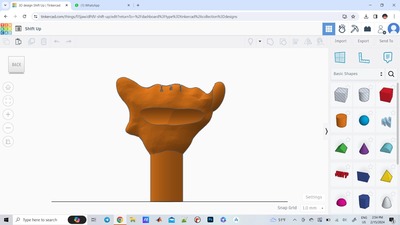

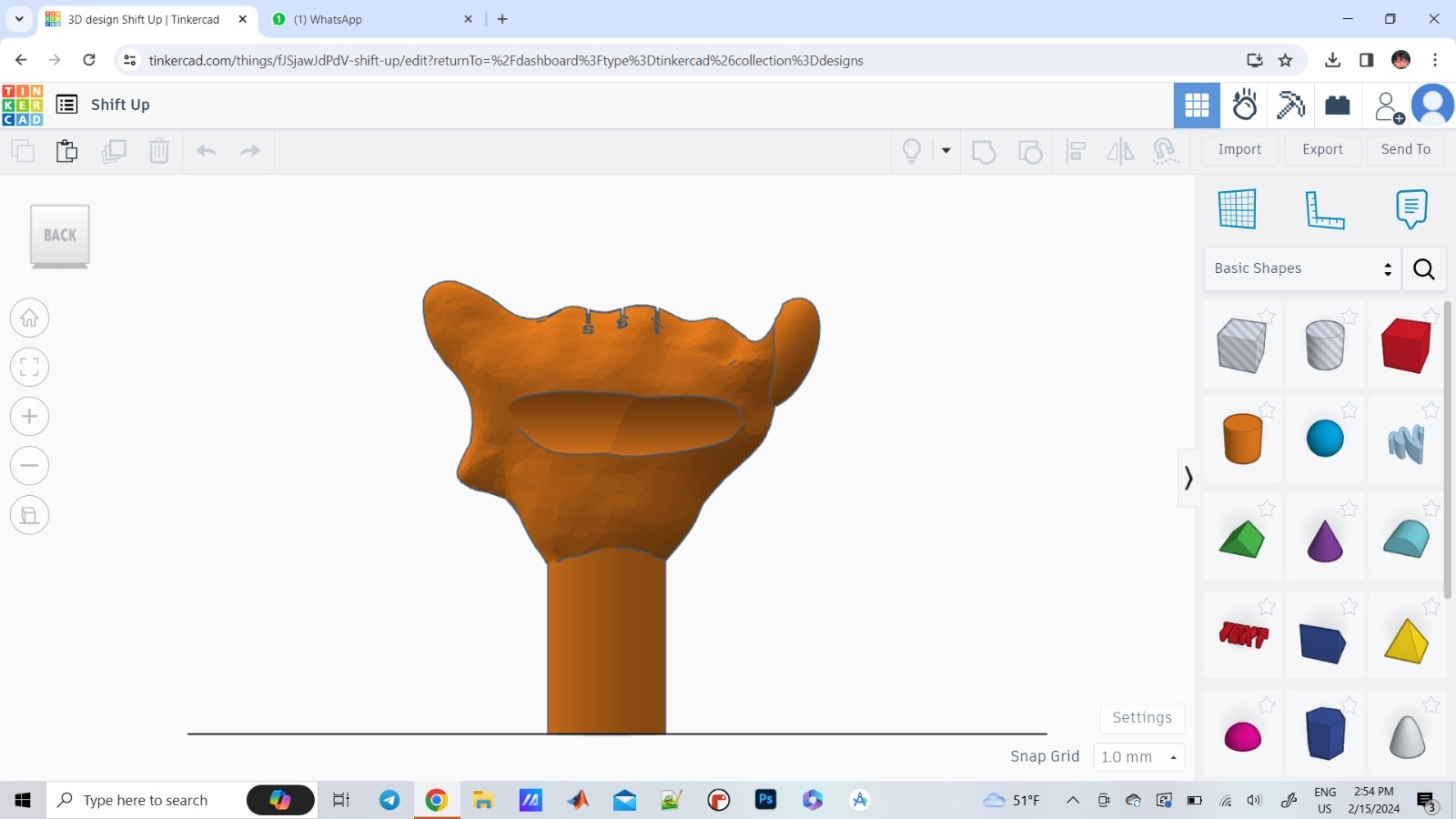

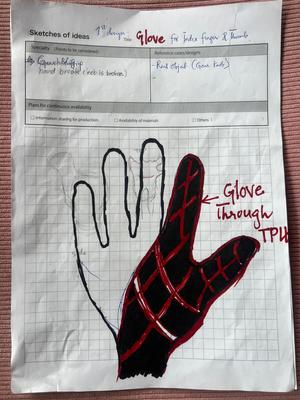

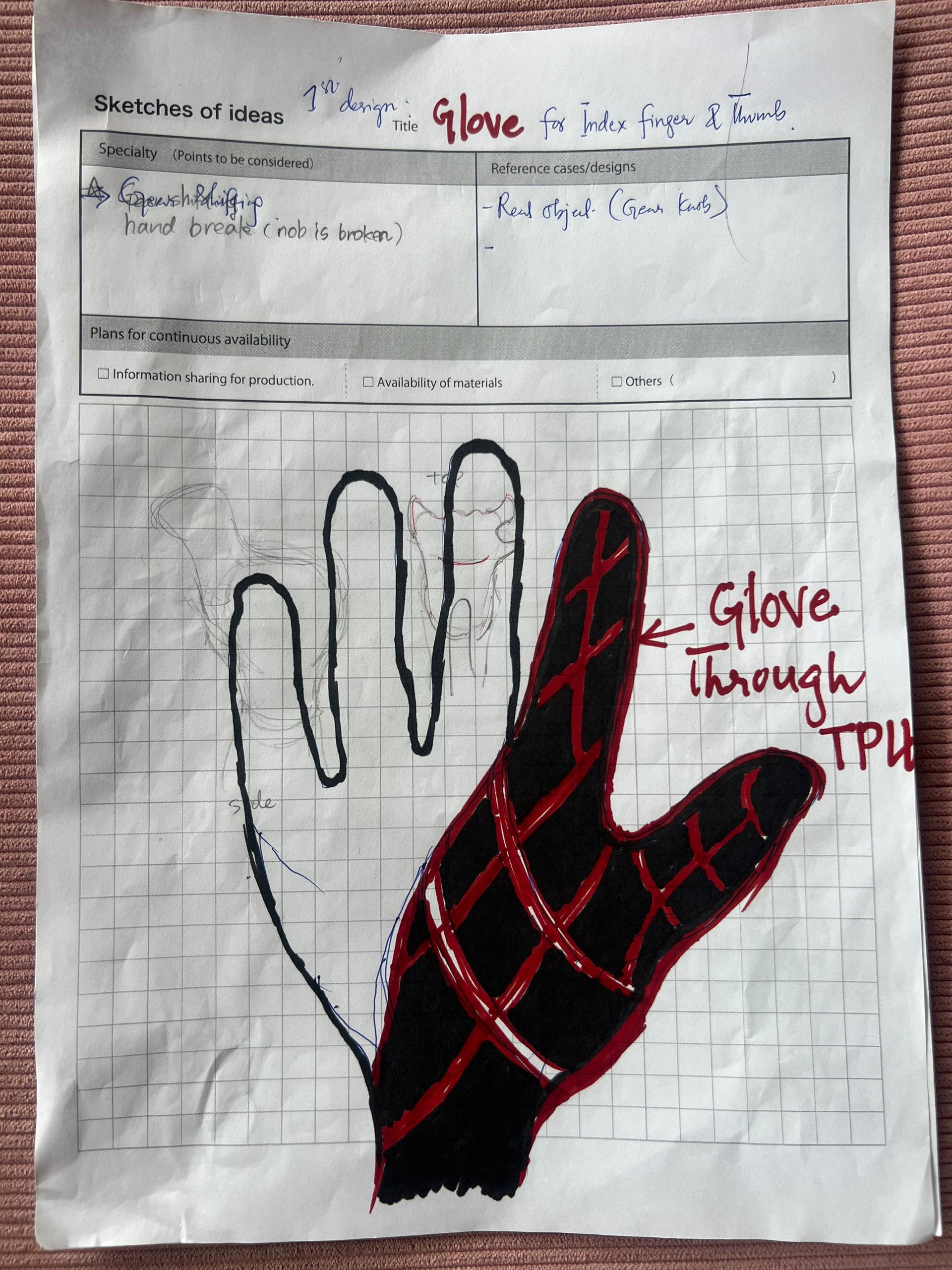

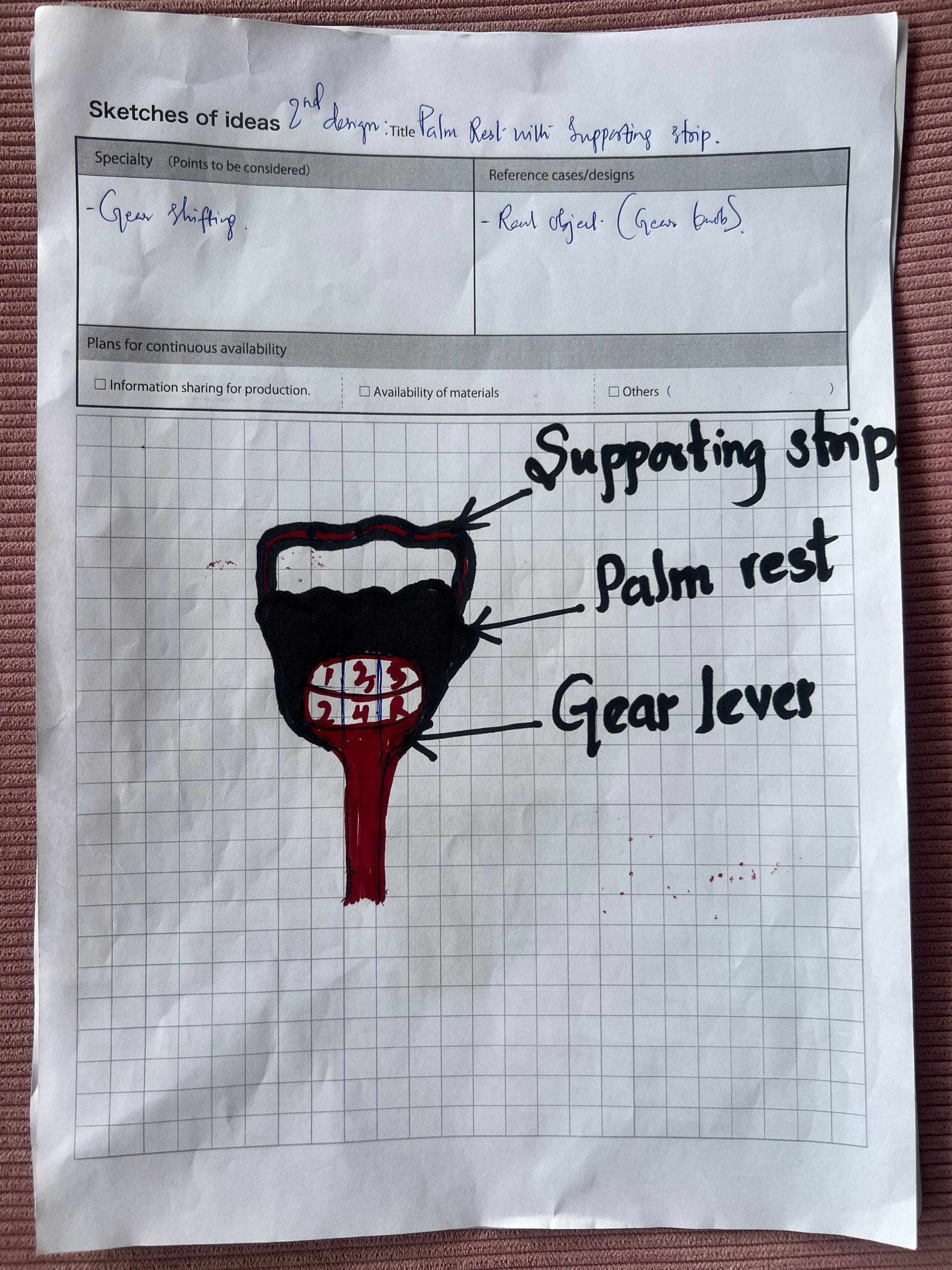

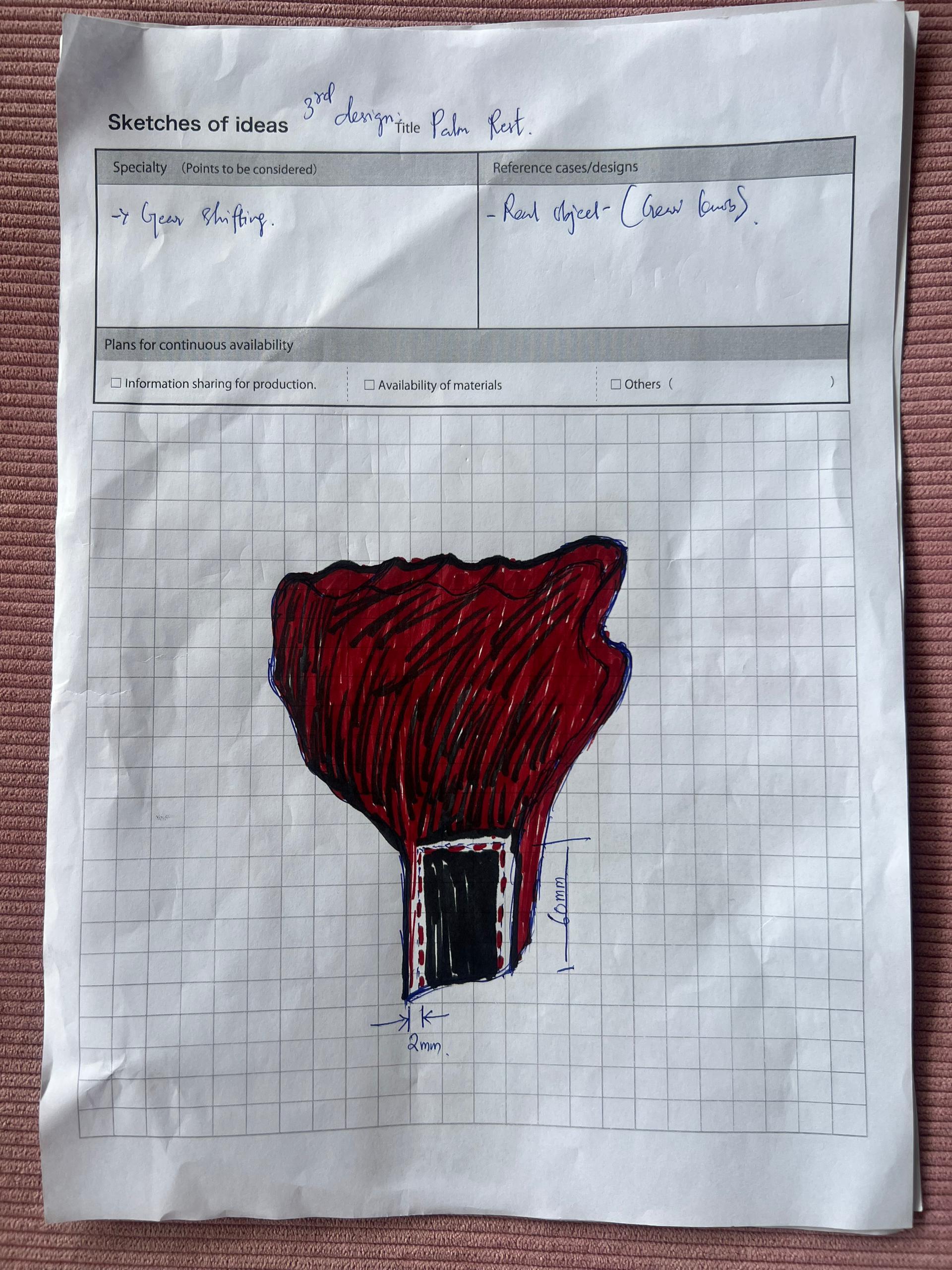

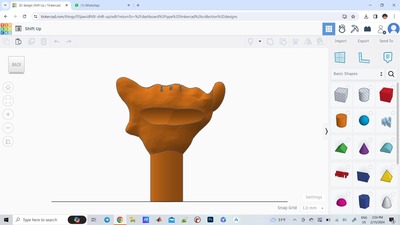

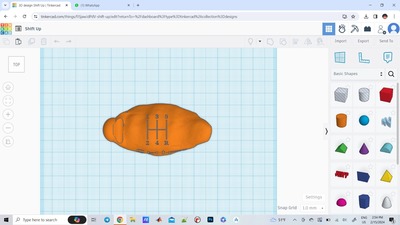

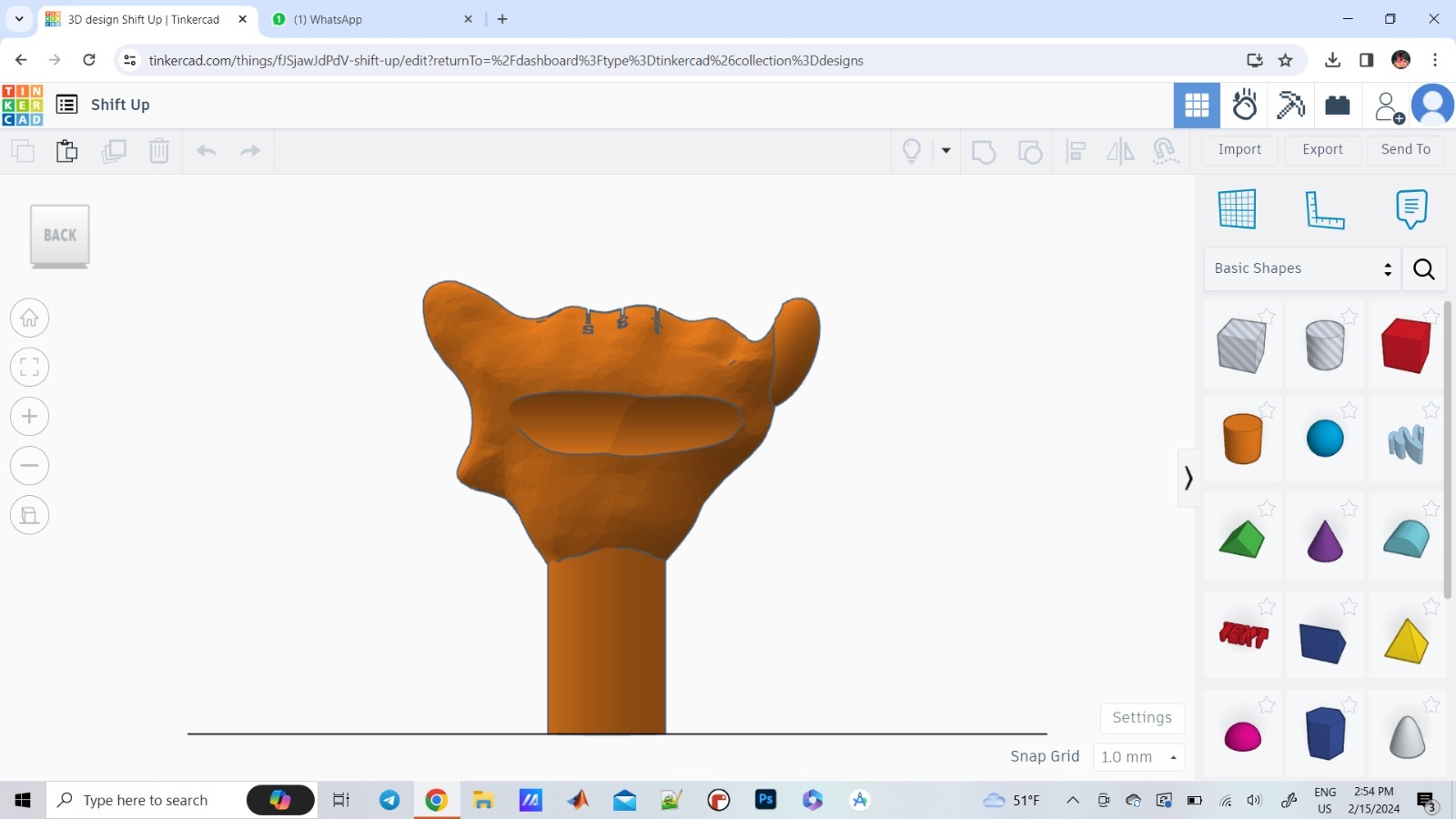

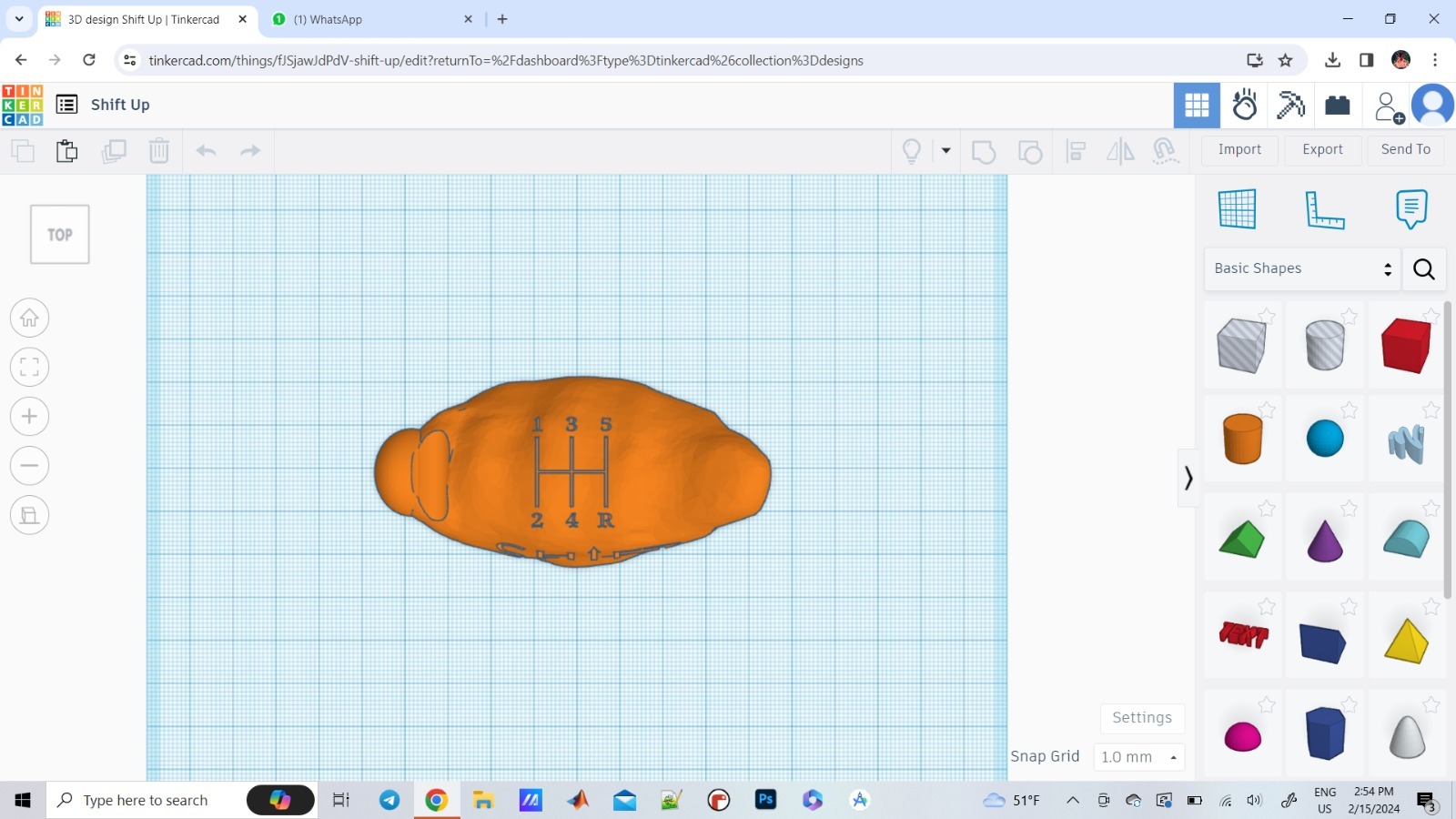

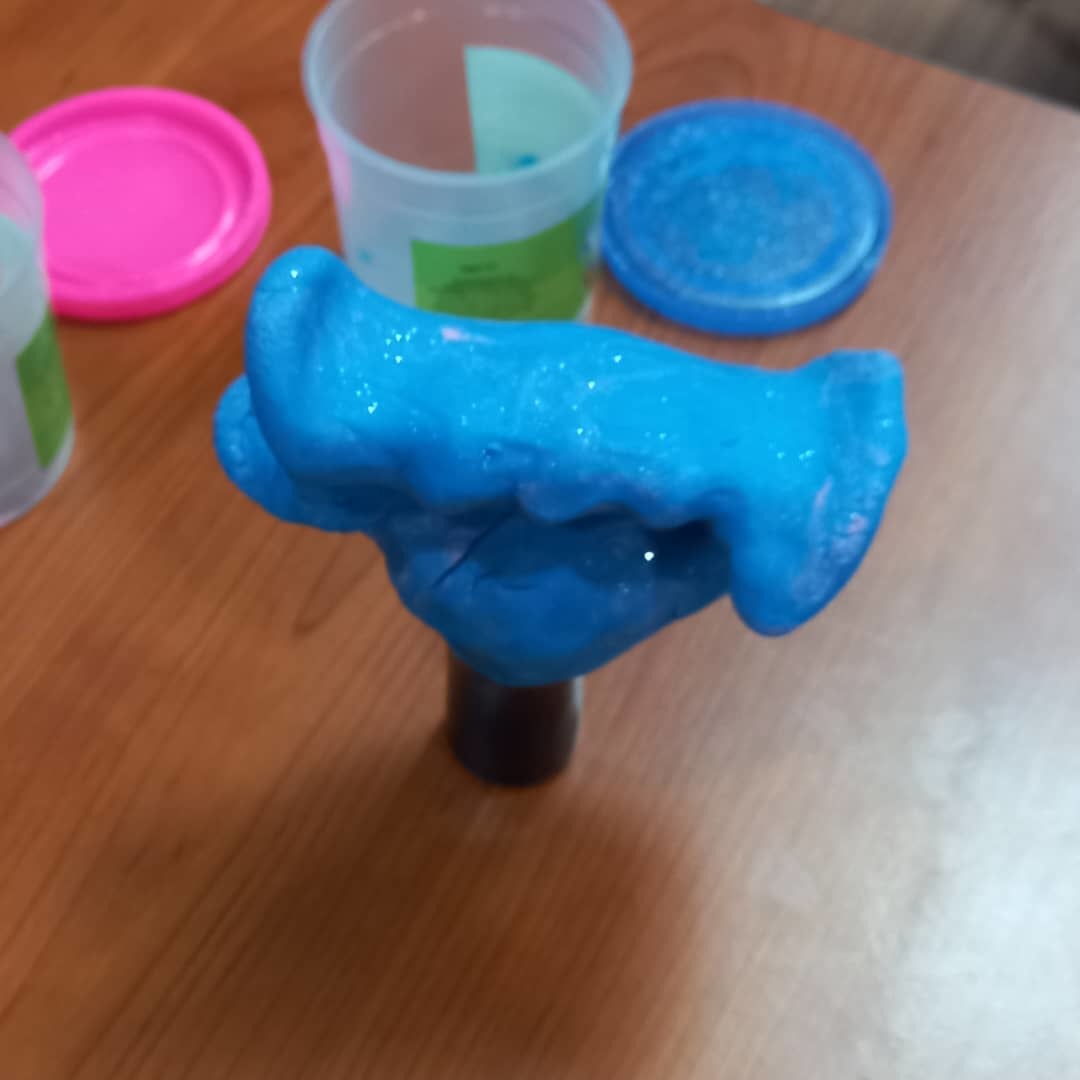

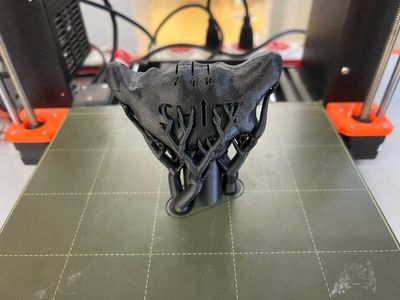

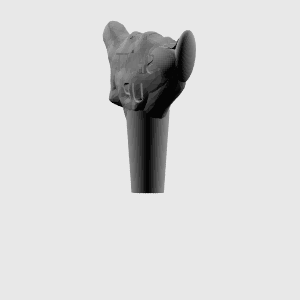

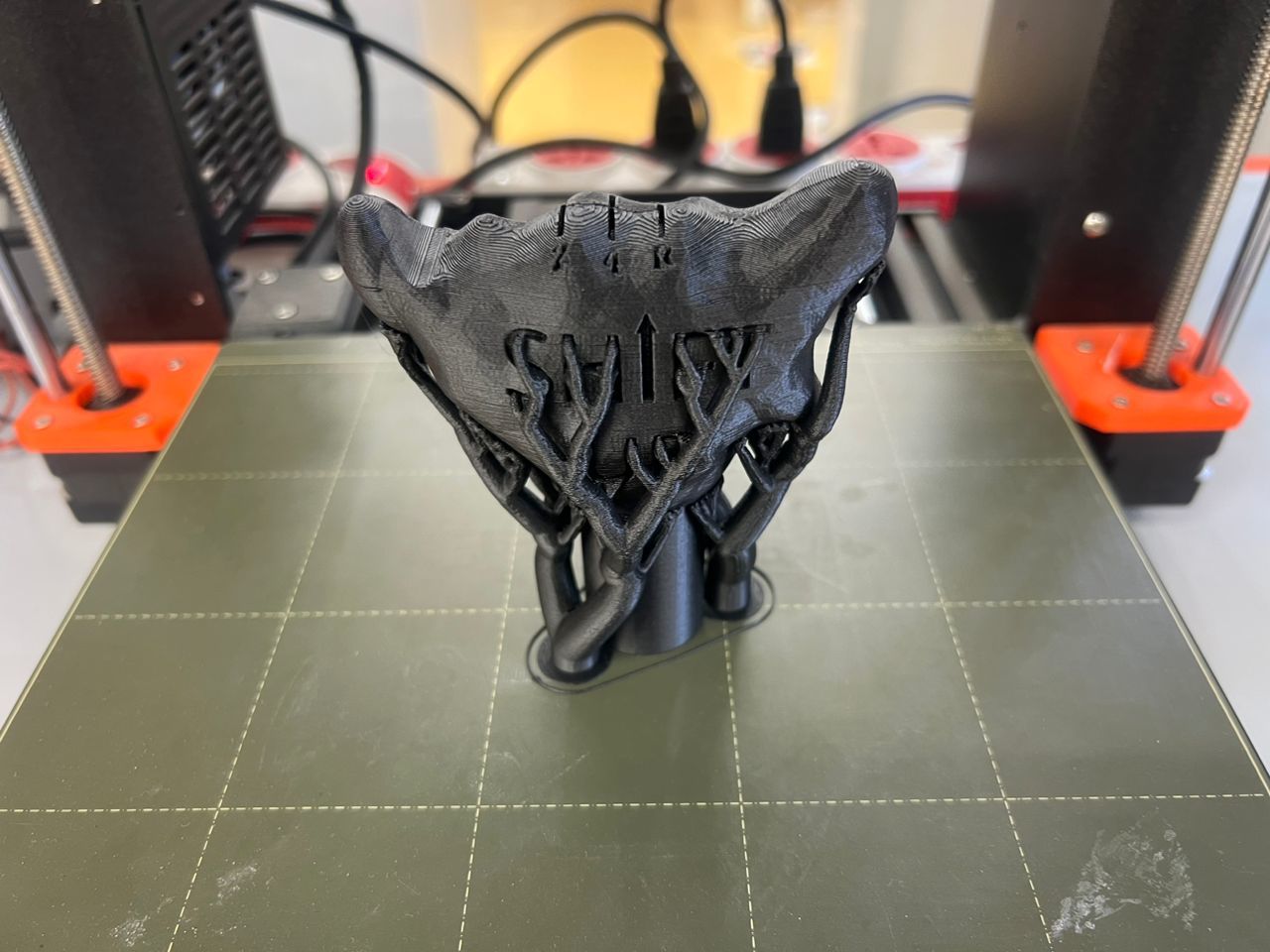

Following a stroke in 2022, Mr. Jari Lal Gurung's left half of his body is paralysed. In order to provide for his family, he began driving taxi last year. He can't shift gears easily because his fingers and thumb get tense. If he can have the device to support his finger it would be great help.

Comments