- Name: Anukala Rai

- Age: 33 years old

- Background: Born in Khotang, Studied arts, Trained as a Beautician, Avid Sports Woman

- Interests: Beautification, Lawn tennis, Swimming (Can't Pursue)

- Strengths: Resilient, Resourceful, and Independent

- Social Role: Motivation for the Society

- Disease: Transverse MyelitisClinical Manifestation: Laxmi Puja, 2071 BSHospitalization Duration: 2 yearsPhysiotherapy & Rehabilitation: 3 yearsAdditional Info: Made many friends facing similar cases, found supportive community after reaching SIRC-Nepal.

SARMA_Nepal2025 Team2 - Team SAMABESITA

Owner & Collaborators

License

SARMA_Nepal2025 Team2 - Team SAMABESITA by FablabShinagawa, Krishna, Ravin01, AshishTM-fabble, Sunitashrestha, AshishThapa, isharashahi is licensed under the Creative Commons - Attribution license.

Summary

In the SARMA Nepal 2025, Our need knower, Anukala Rai came with hope for wheelchair improvements which would be able to move in sloppy plane easily, and also to obtain an desired option to open and close her heavy shop shutter, hold her legs in position while riding scooter, &/Or able to grab things from higher height by self.

This project, being performed by Team SAMABESITA, is to fulfill her above mentioned needs as much as possible.

This project, being performed by Team SAMABESITA, is to fulfill her above mentioned needs as much as possible.

Materials

Tools

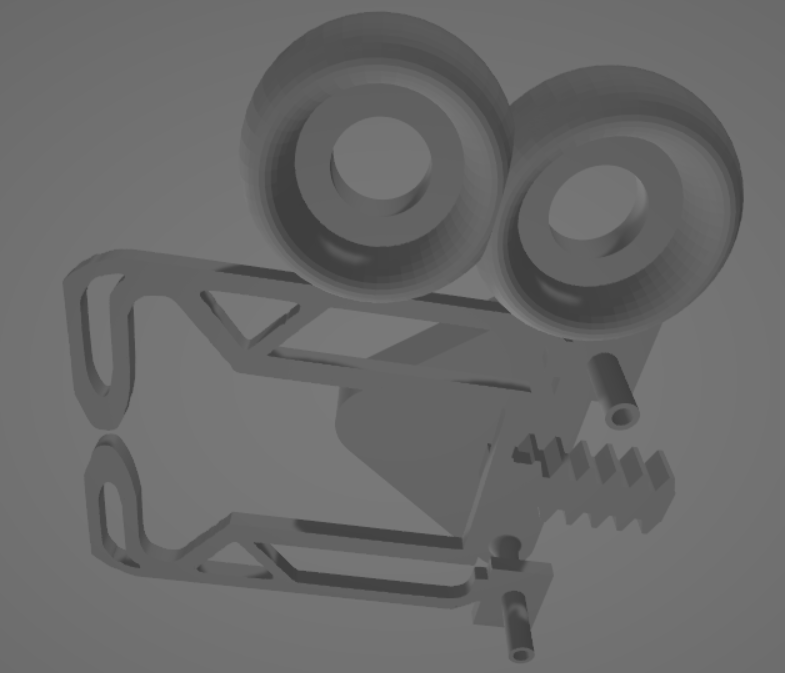

Blueprints

Making

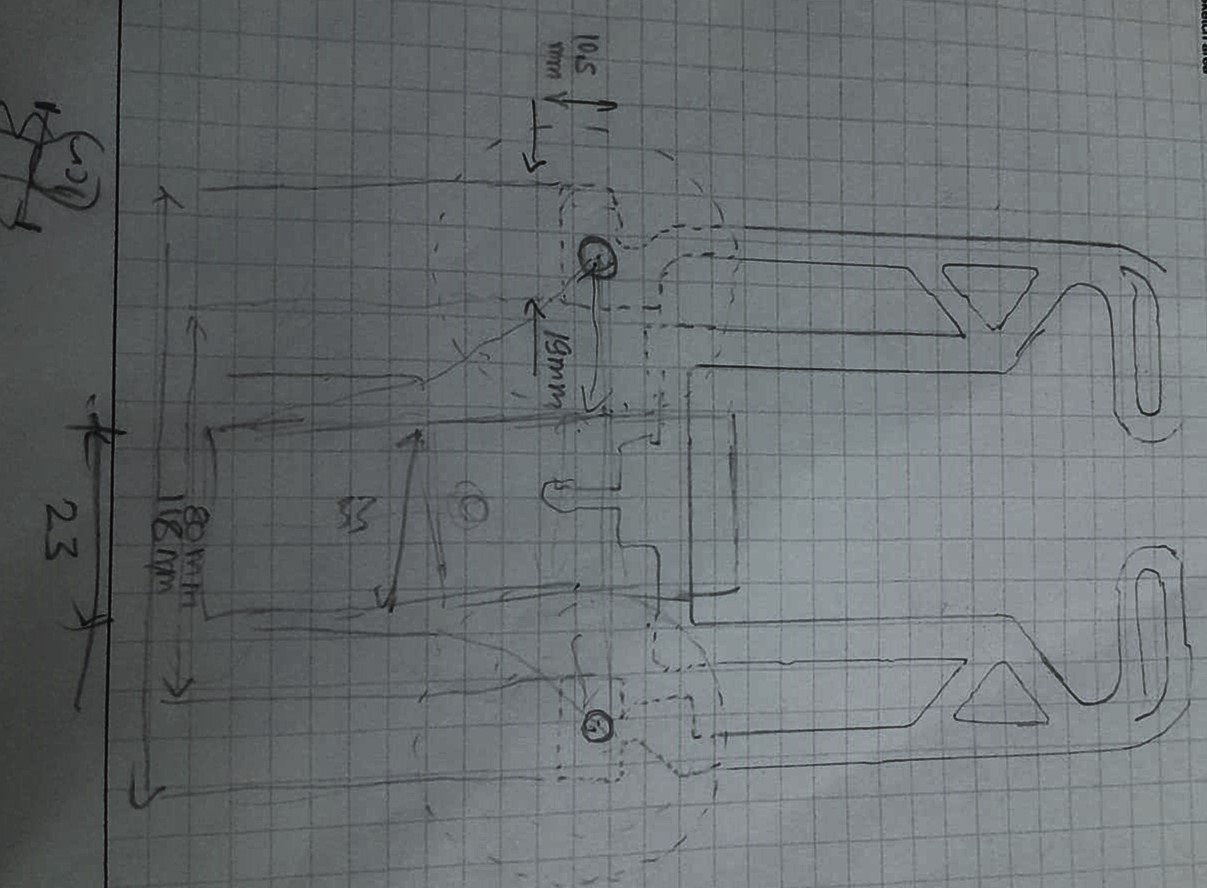

- Mobility: Limited to wheelchair access

Transport: No scooter modified for carrying wheelchair

Physical: Paraplegia (Below Neck: No Mobility & Sense, Left Hand: Decreased Mobility)

Daily: Cannot open and close shutter, Difficulty in moving sloppy plane

Work-Related: Inability to reach higher height

- Design Gripper Cane to grab things on higher heights

- Design Rope Puller & Wheelchair Uplifter to move wheelchair on sloppy plane by self

- Design Tie Band to hold legs while riding scooter

- Design Screw Jack + Gear to operate shop shutter

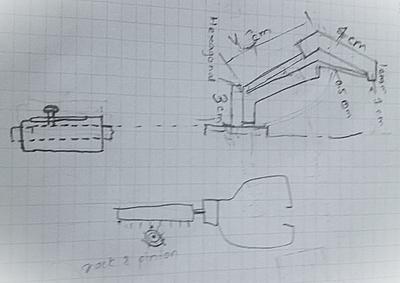

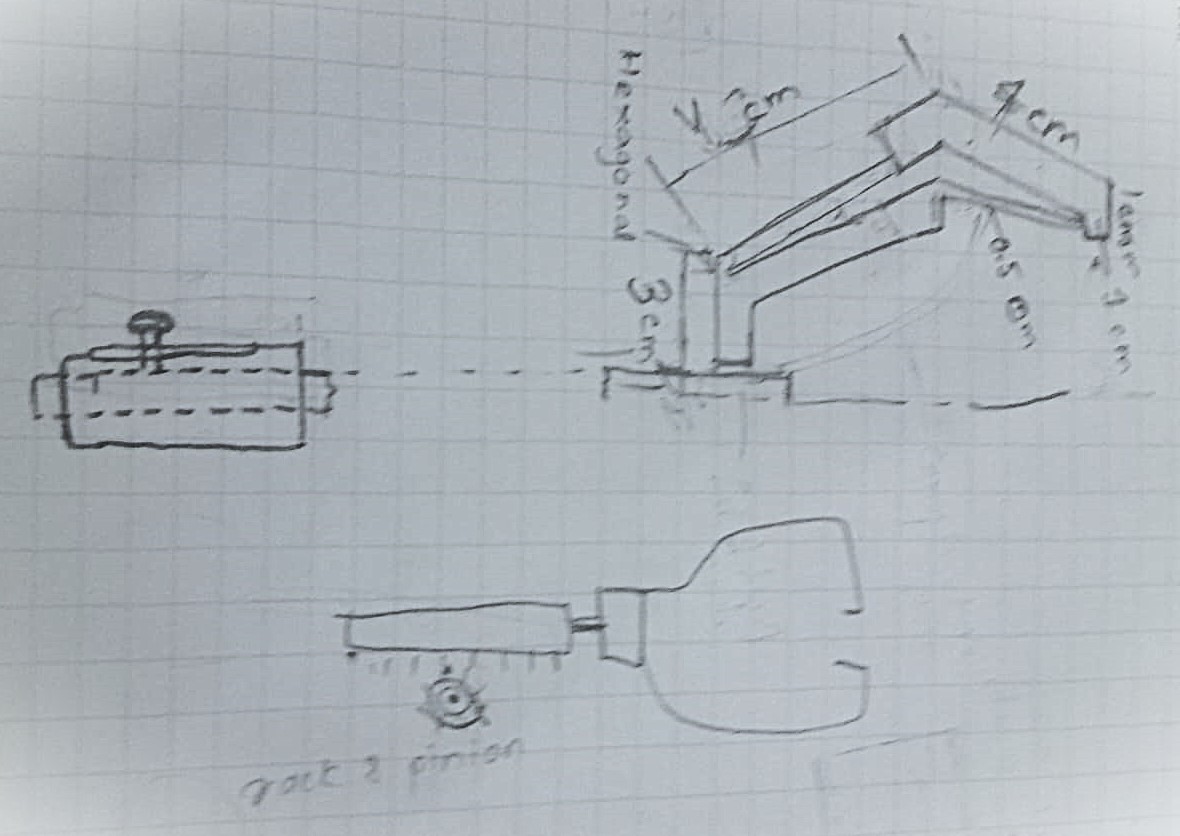

- Modelled a 2D sketch with hexagonal shaped model using Complaint MechanismIdeated a solid rod to power the deviceDesigned push-pull-lock-unlock mechanism at the end of the cane handle for applying effortShortcoming:Failed at utilizing concept of Complaint Mechanism

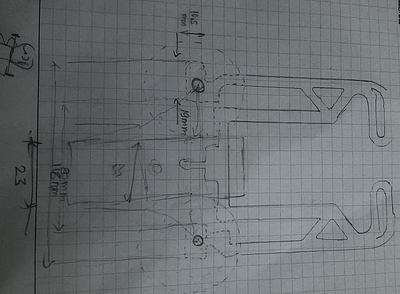

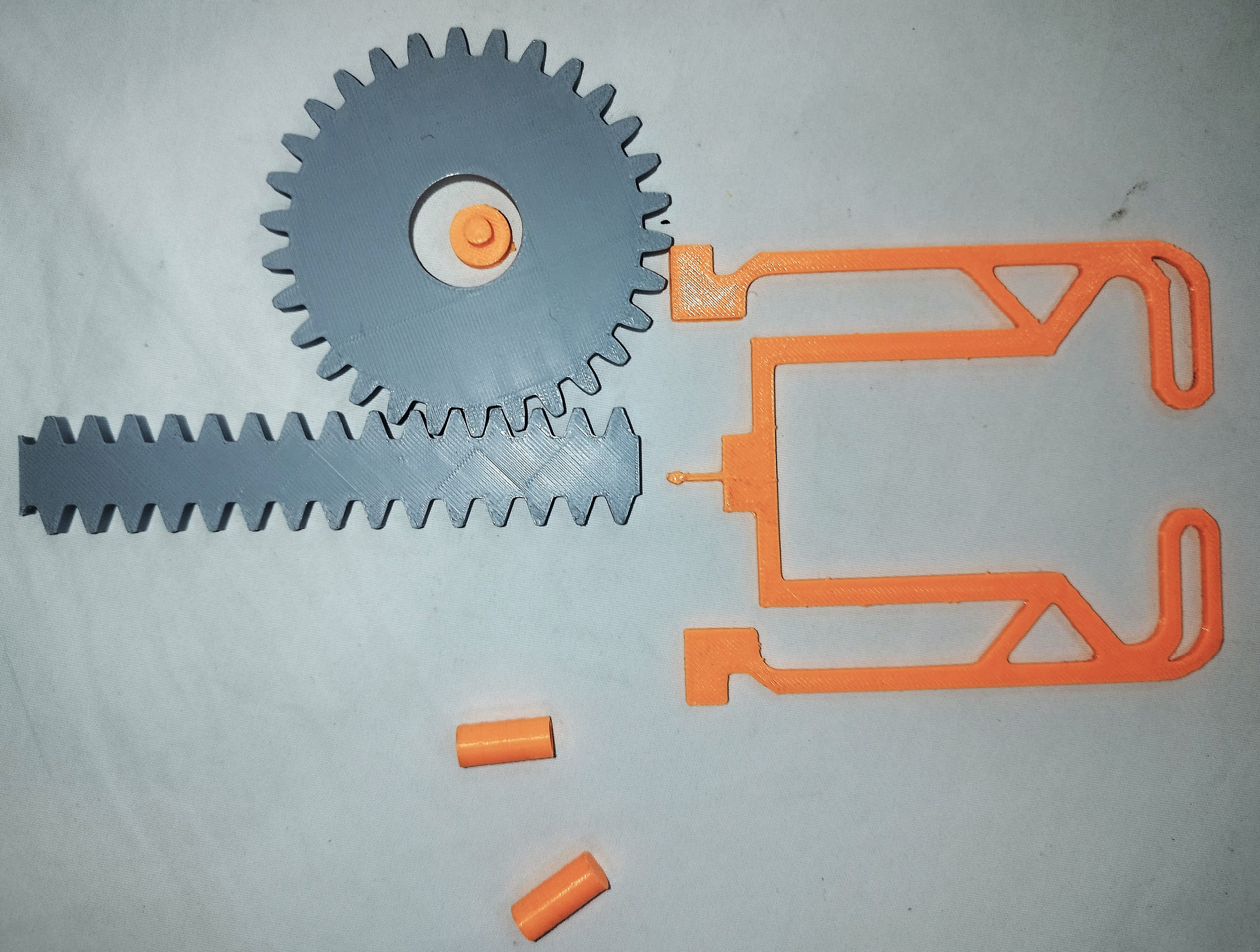

- Used simple model of Complaint MechanismAdded Rack & Pinion Mechanism for applying supposed bidirectional effort on Complaint MechanismRedesigned the handle with Lever MechanismReplaced rod with rope for feasibility and availability

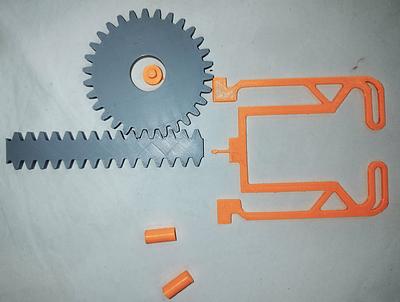

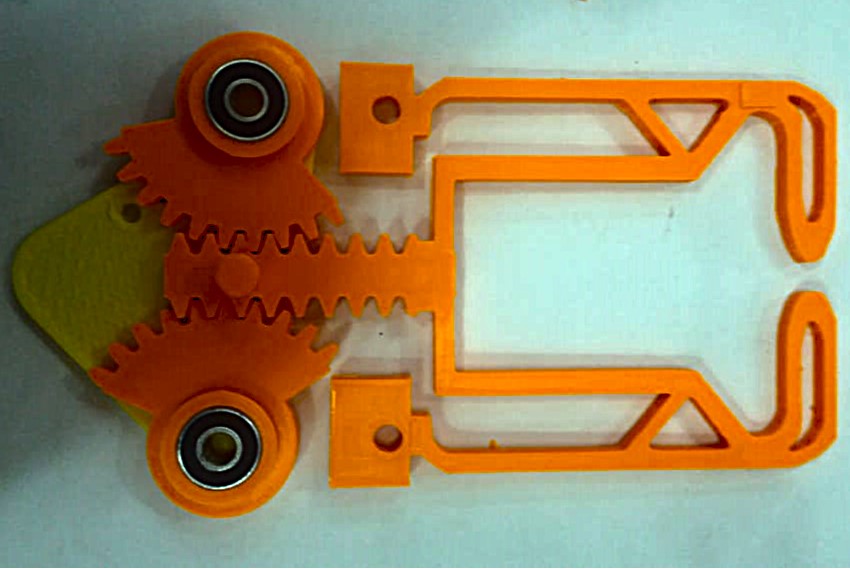

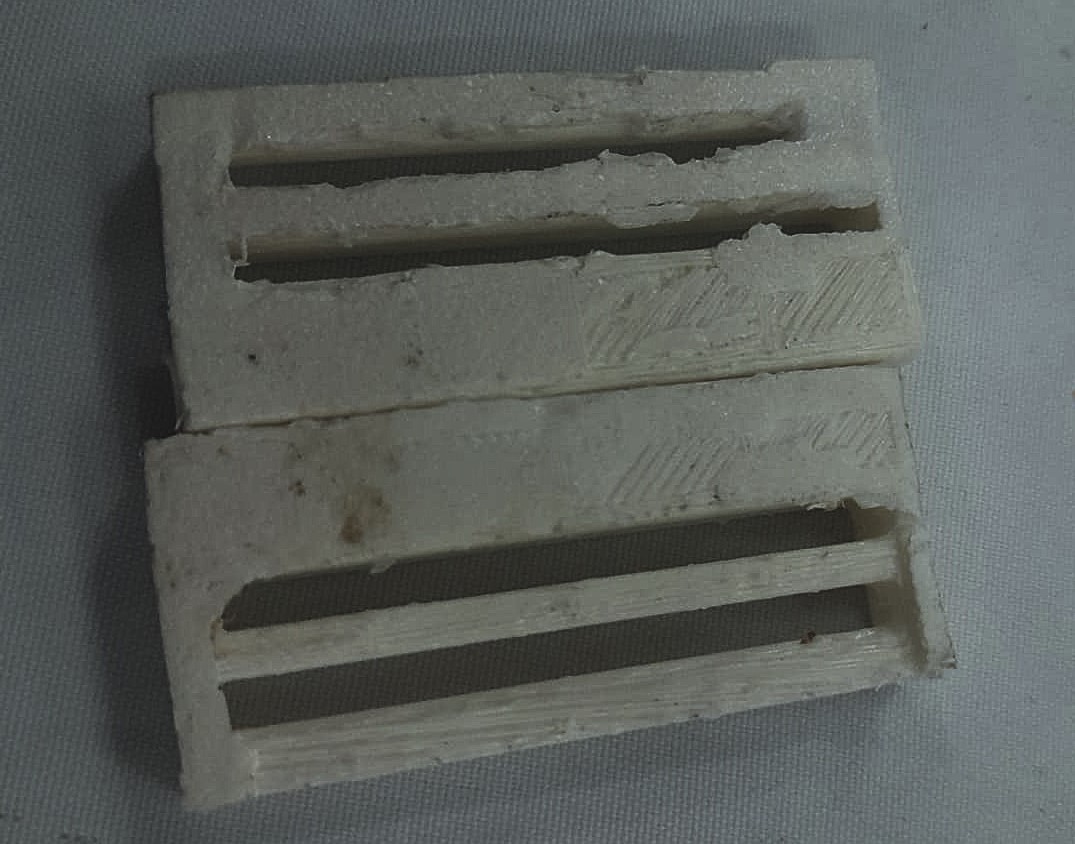

- Directly produced the model in slicer softwareApplied 15% infill contentPrinted 3D rack and pinion, and the complaint mechanism separatelyUsed for initial testing to determine usefulnessShortcomings:Larger pinion than idealized modelLacking strength

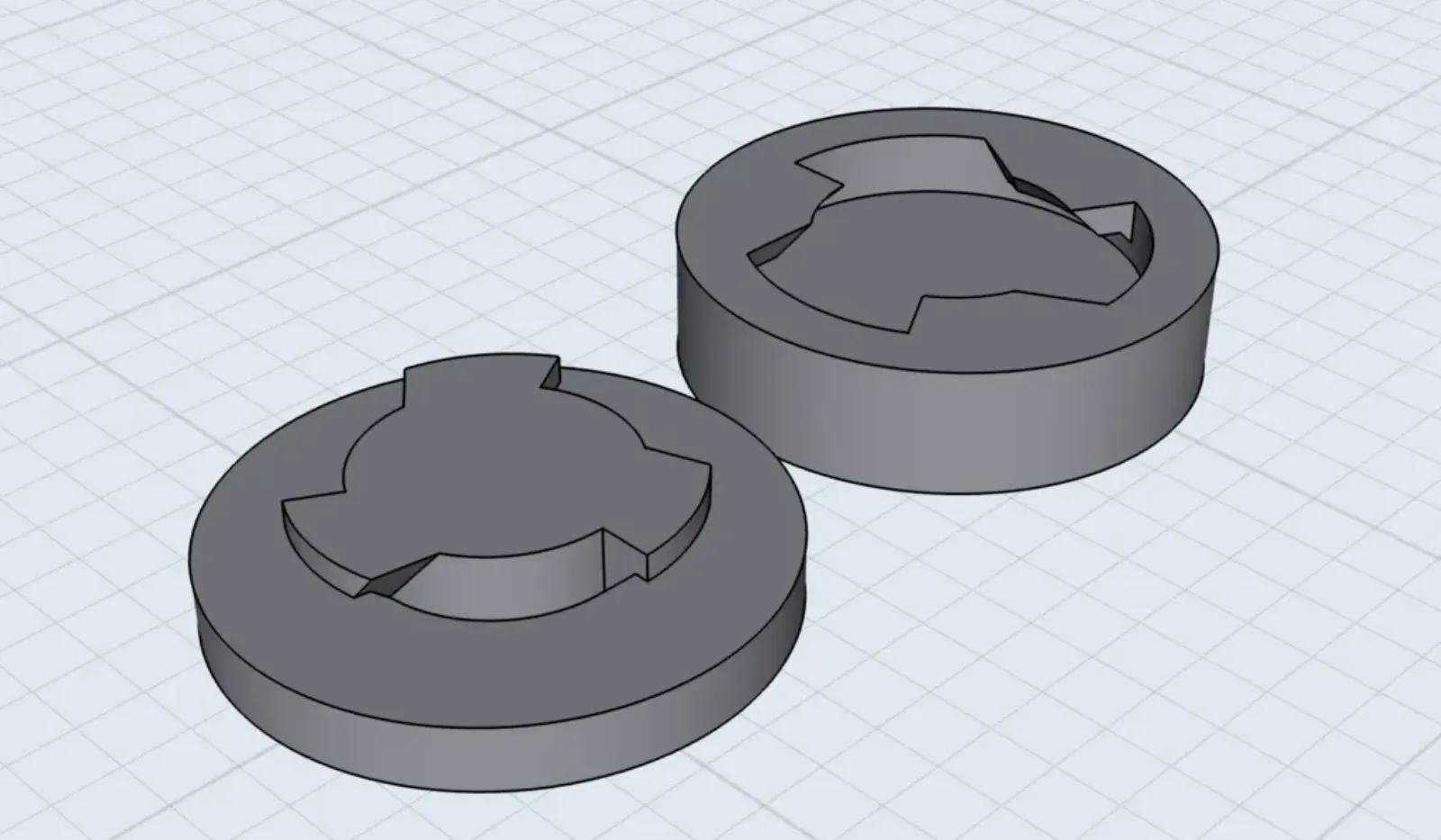

- Designed the part double gear mechanism for the rackAdded the base part for the gearsAdded bearing and pinsShortcomings:Limited motion due to rigid structureLess teeth distance to catch or hold large thingsMisplaced rack model on the complaint mechanism

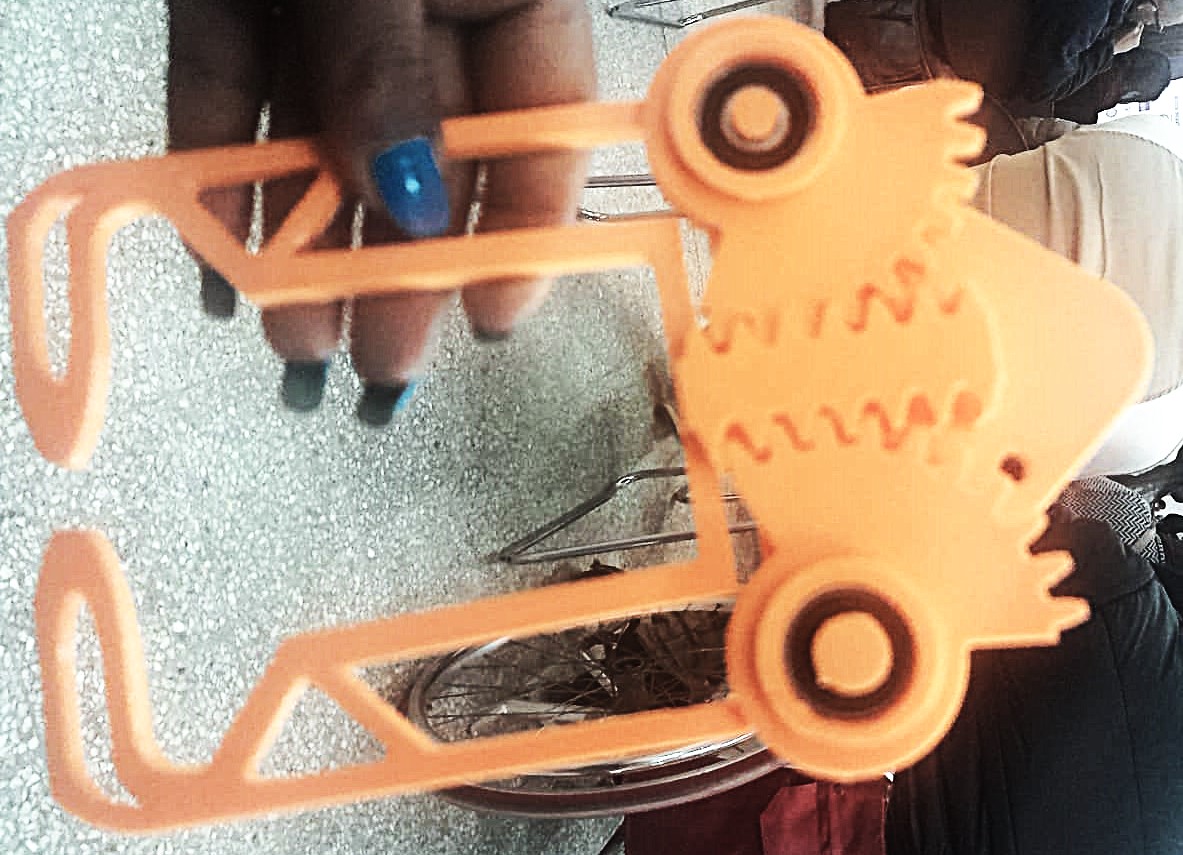

- Directly modified the model from slicer software from initial designSuccessfully made functional 3D printed model of 'gripper' part

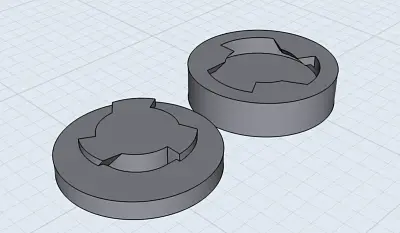

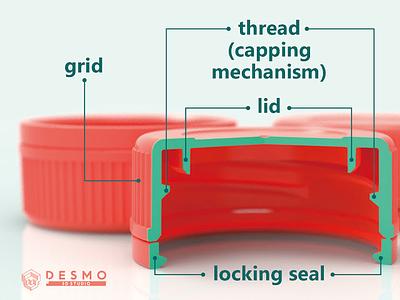

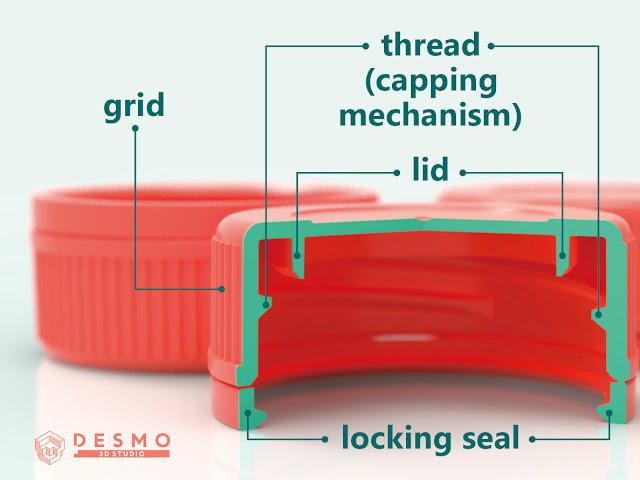

- Applied 15% infill contentShortcomings:Found faults in thread tolerable designCouldn't scrap out the support infill because of narrow and small tie-band strip holderWearability and screw clearance issuesReconceptualized:Decided to use Clip Buckle model instead

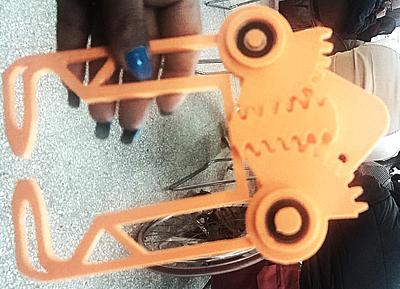

- Used ABS, TPU, and PLA filaments for 3D printingApplied 15% infill content for initial testingApplied 30% infill content for the final productSuccessful 3D printing of Usable Clip Buckle

- Modified Clip Buckle was found to be successfully working

- Need Knower was very satisfied with the Modified Clip Buckle model despite its tightness in functioning

- 3D printed Gripper Cane model required other unprinted parts to be printed for full testing.

- The printed Gripper Cane and Modified Clip Buckle models successfully performed controlled grasping and releasing of objects with precision. For actual use, working of the printed models were tested and obtained necessary feedback from the need knower.

- The 3D printed Gripper Cane and Modified Clip Buckle models were found to be functional, reliable, and adaptable for different applications. They enhanced automation by improving handling efficiency.

- Integration with robotic arms for industrial automation.

- Implementation of advanced control systems for precision.

- Development of lightweight and efficient designs for various applications.

References

Usages

Of the Modified-Clip Buckle modeled

-Modified Clip Buckle is used along with tie band in the need knower's scooter for holding her legs while riding

Project comments

Comments