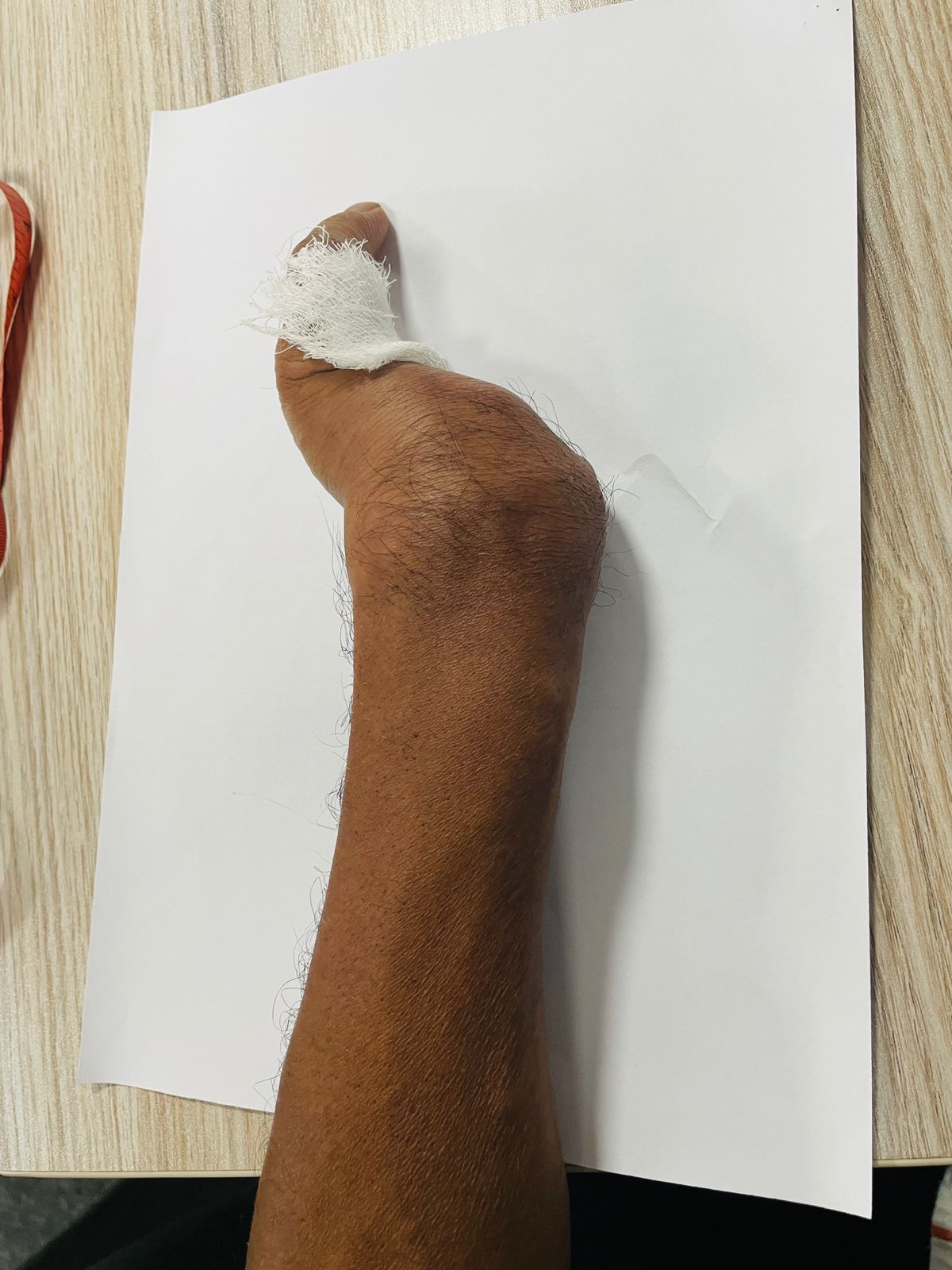

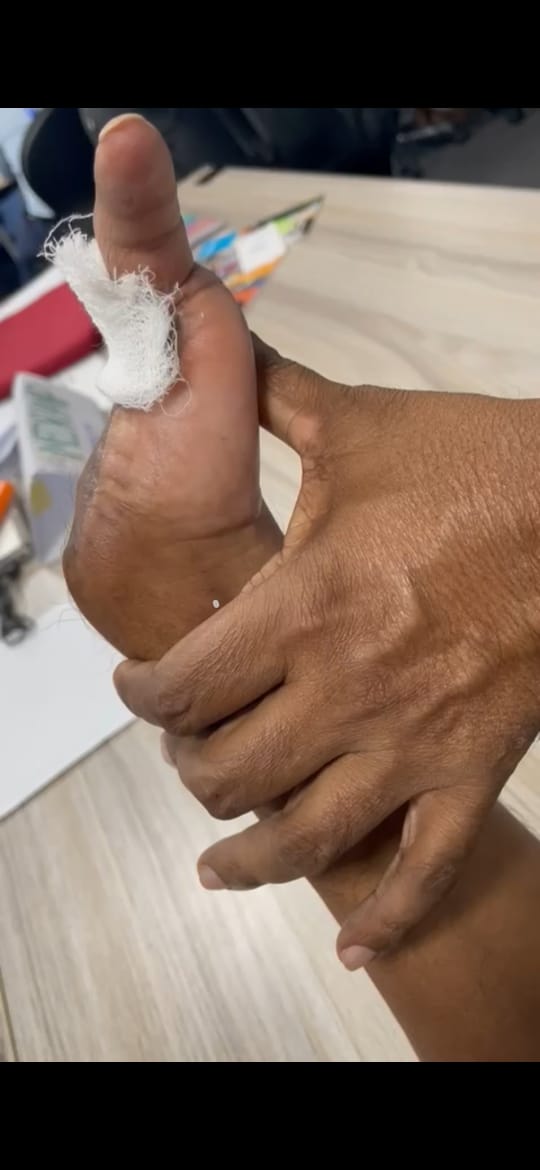

Name - Mr.Ajith Nihal

Age - 55 years old

Ajith is a dedicated farmer

Age - 55 years old

Ajith is a dedicated farmer

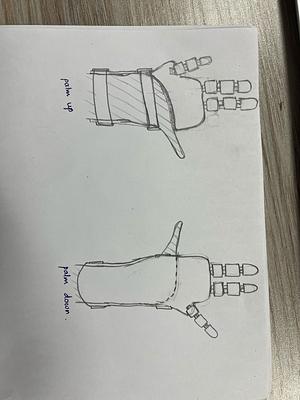

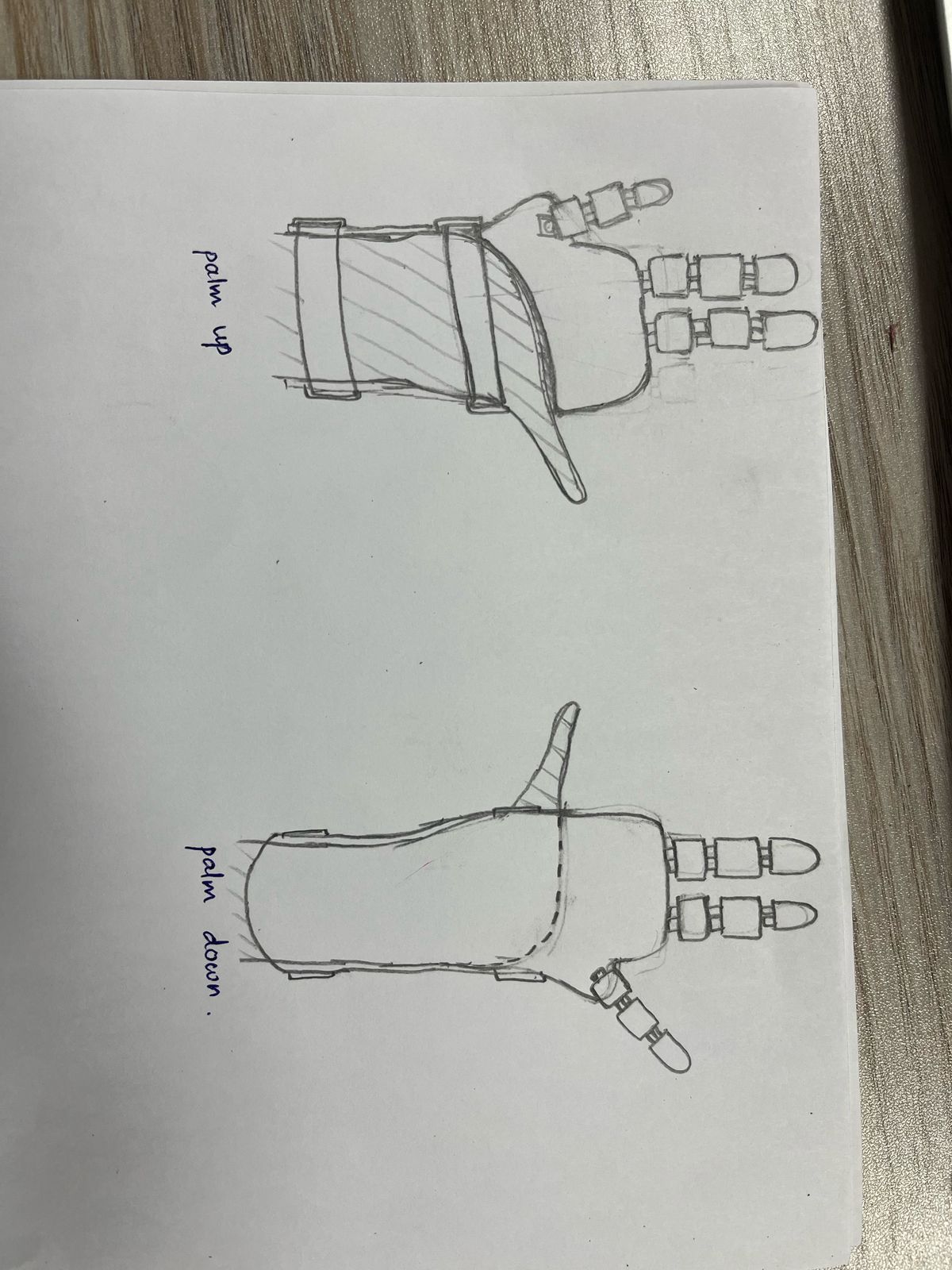

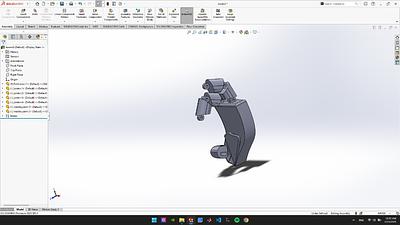

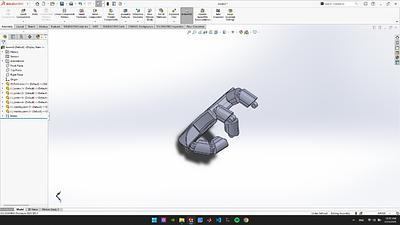

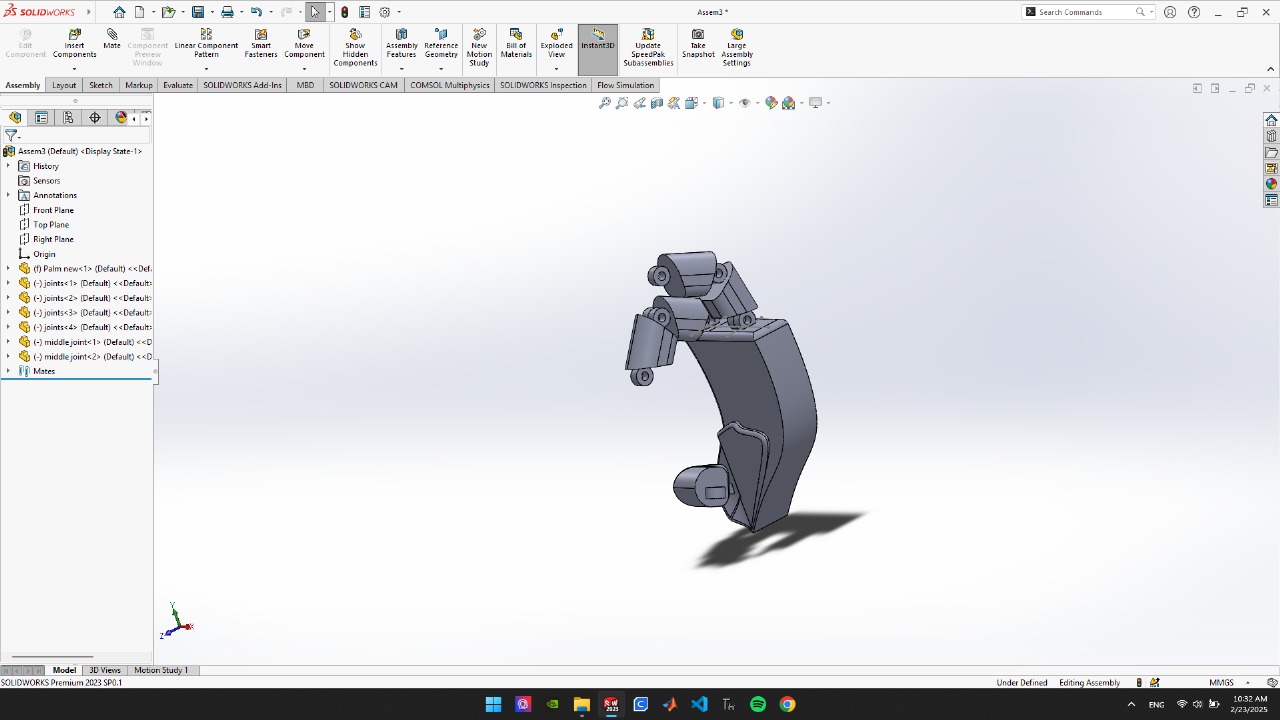

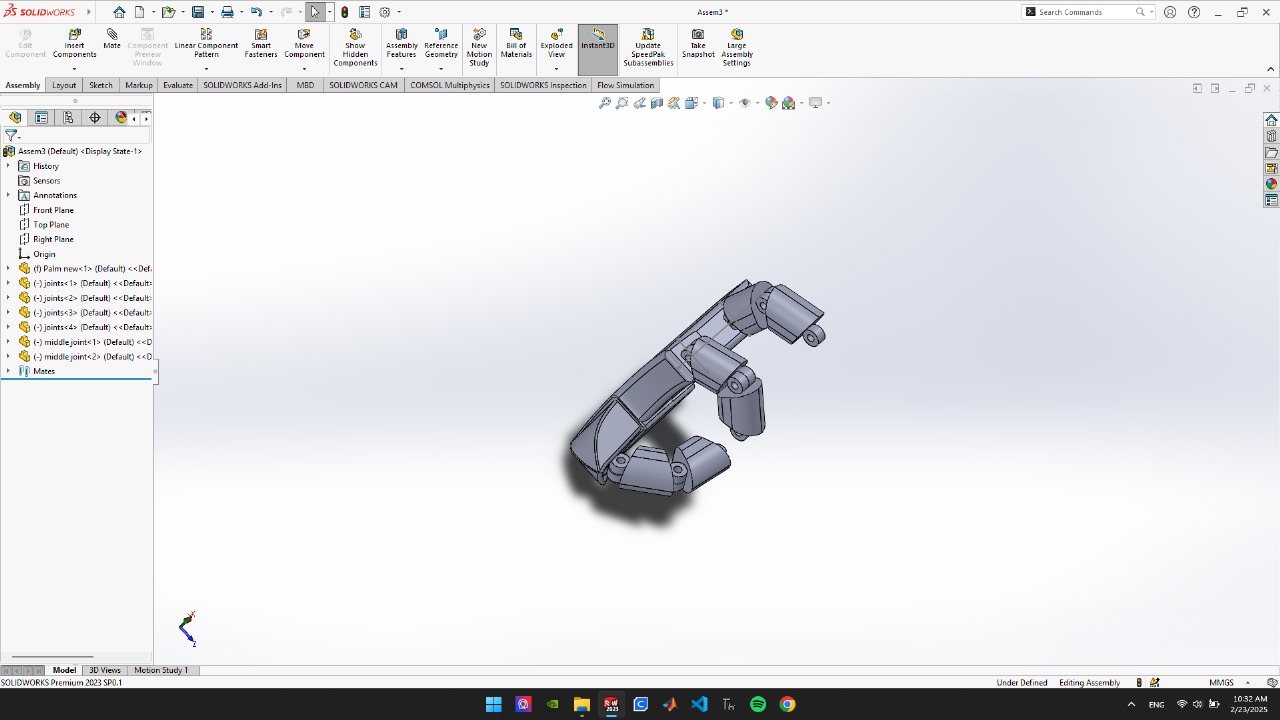

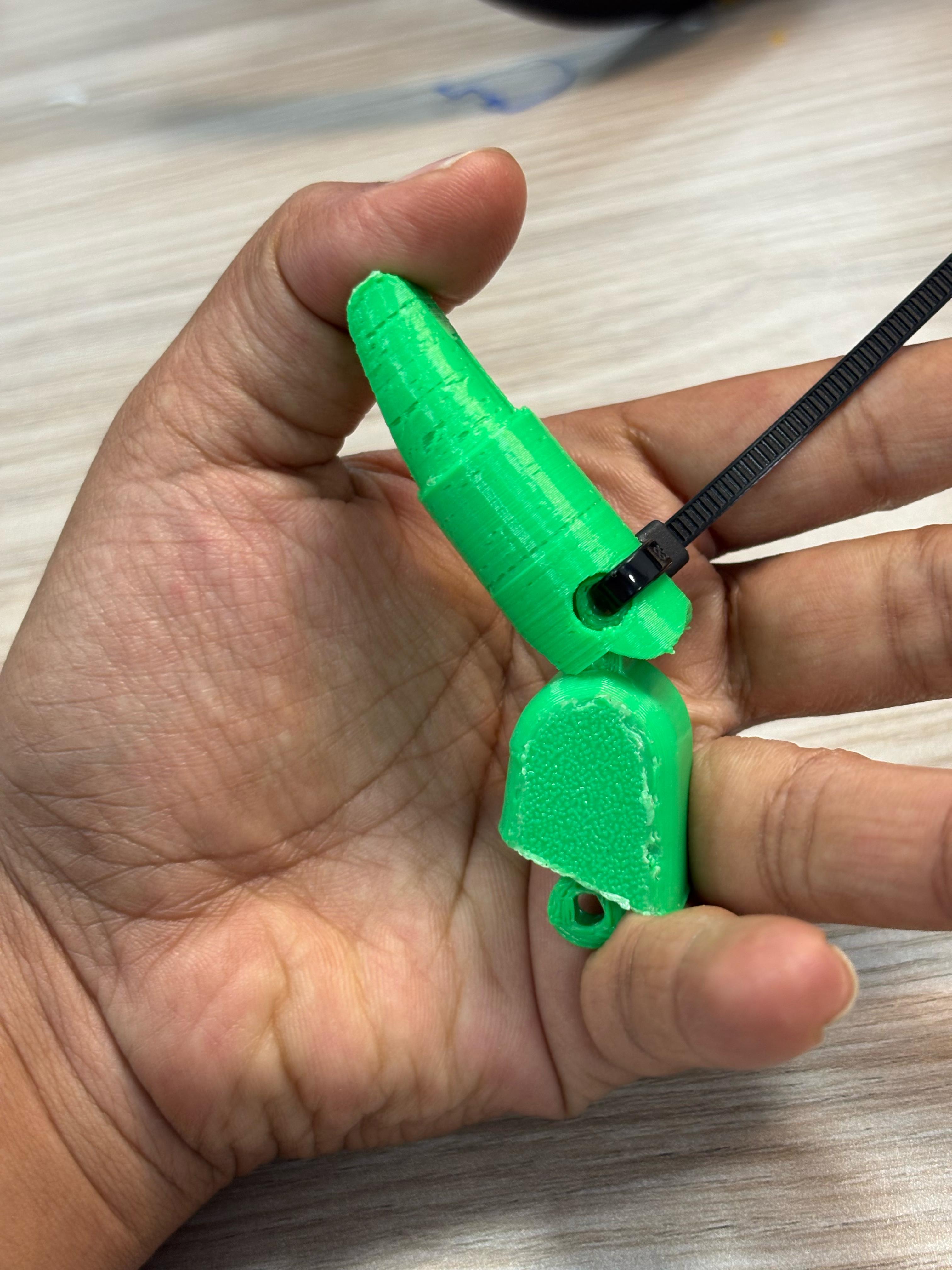

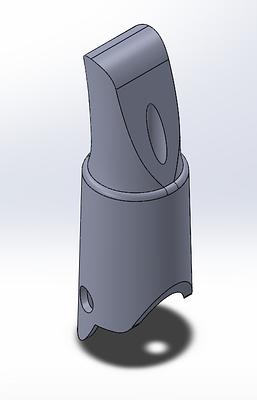

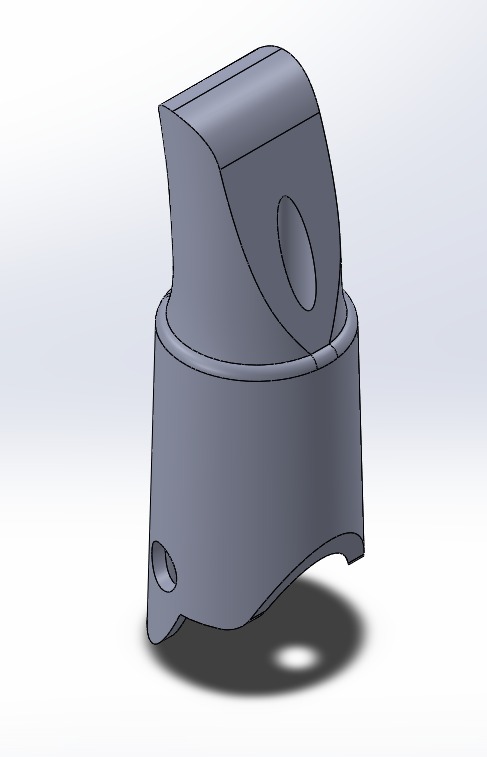

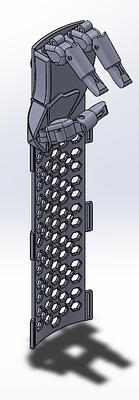

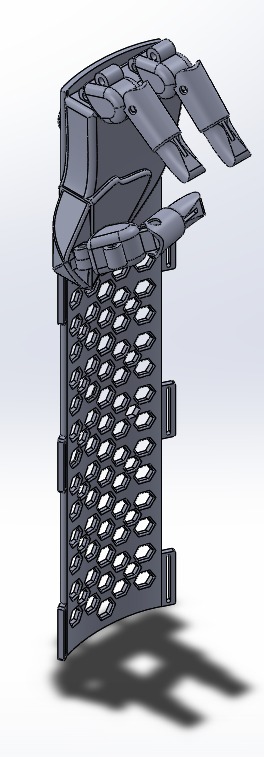

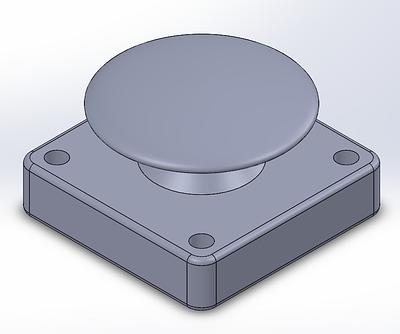

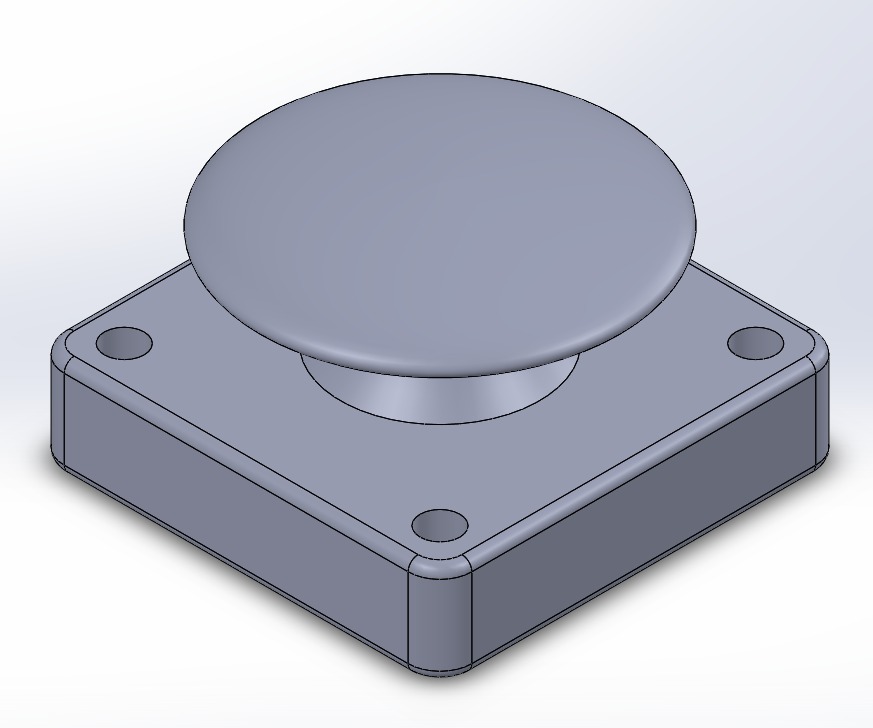

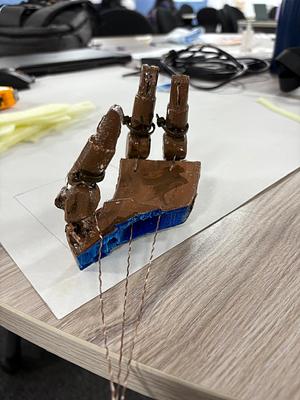

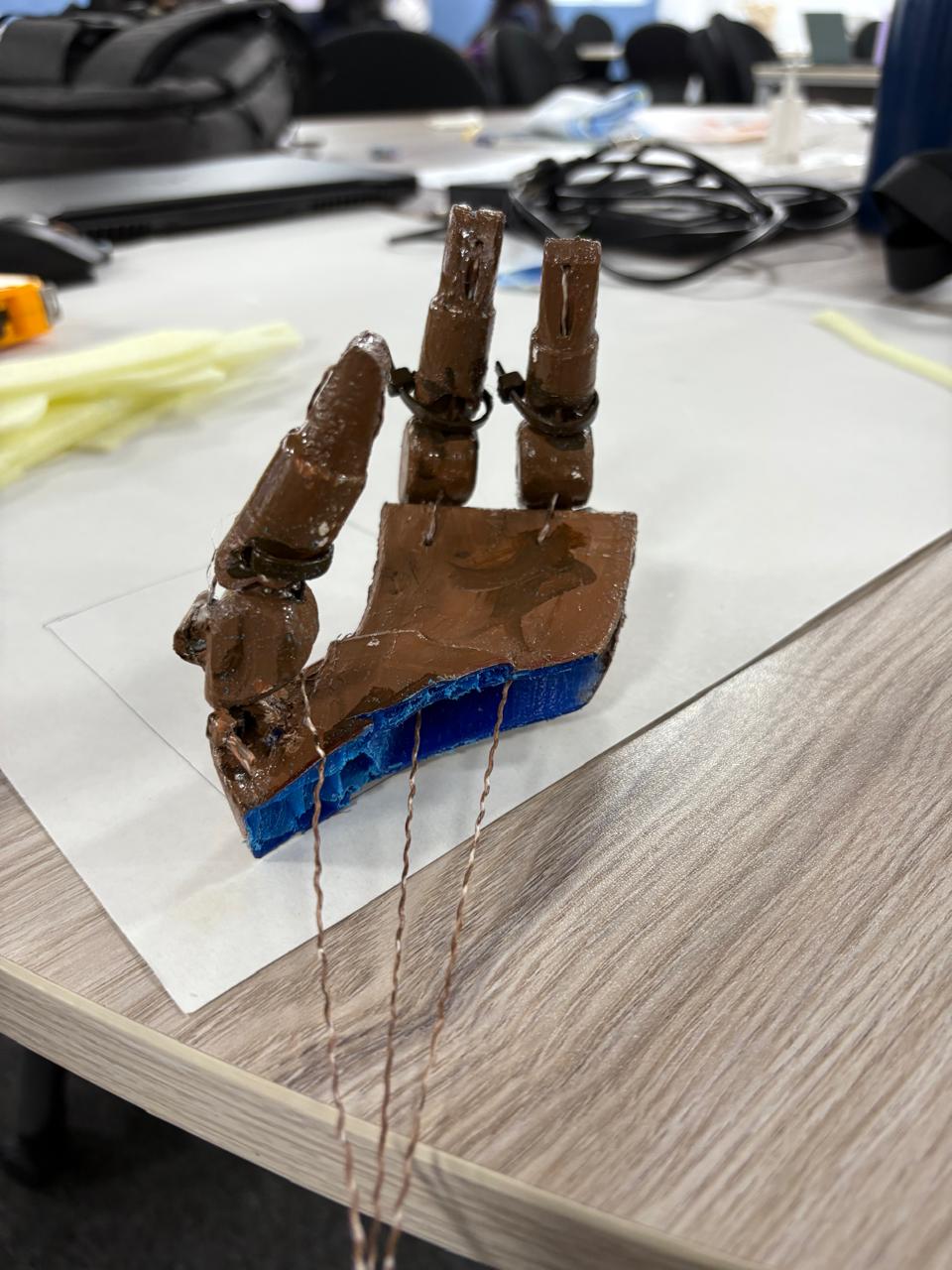

- Mr. Ajith Nihal has lost four fingers in his left hand due to a factory accident. Even though he does not have four fingers he is doing his primary work alone from his dominant hand. Mr. Ajith wants to contribute in his day to day activities especially in farming using both hands

Comments