Every step forward is a step toward possibility. With Fabrication and Assistive Innovations for Therapeutic Help, we are not just building an assistive device—we are building confidence, stability, and the freedom to move without limits.

- Name: Yuto Gautam

- Date of birth: 2013/06/06

- Parents: Bandana Poudel, Lal Chandra Gautam

- Language: Nepali

- Hobbies: Watching tv, Playing games

- Yutu is a 12-year-old girl has Down syndrome and a three-chambered heart. The following are the challenges she faces in her daily life:

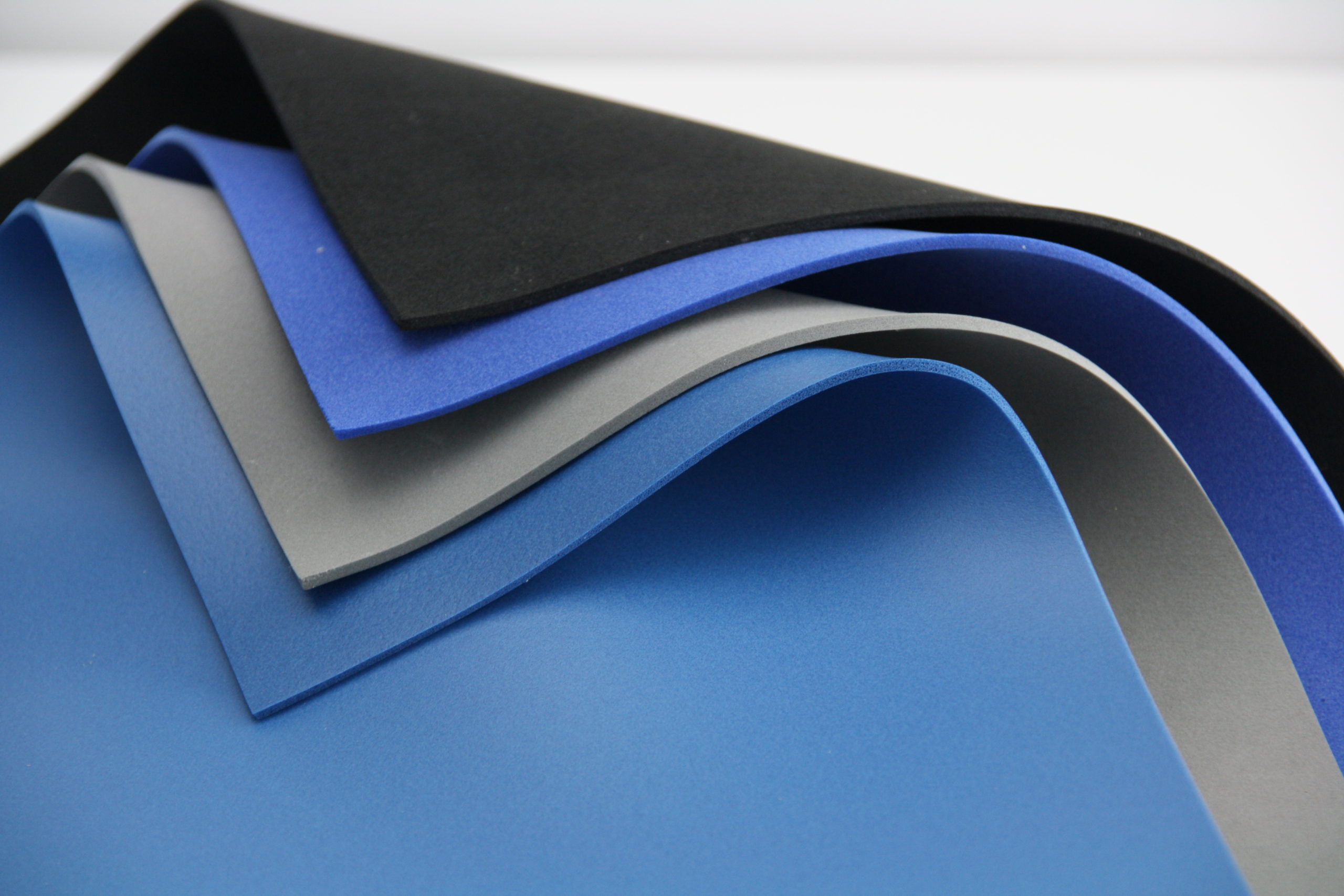

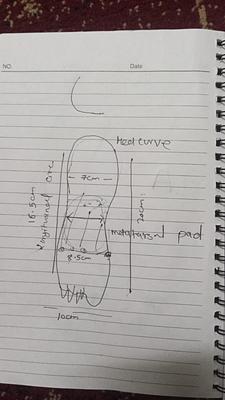

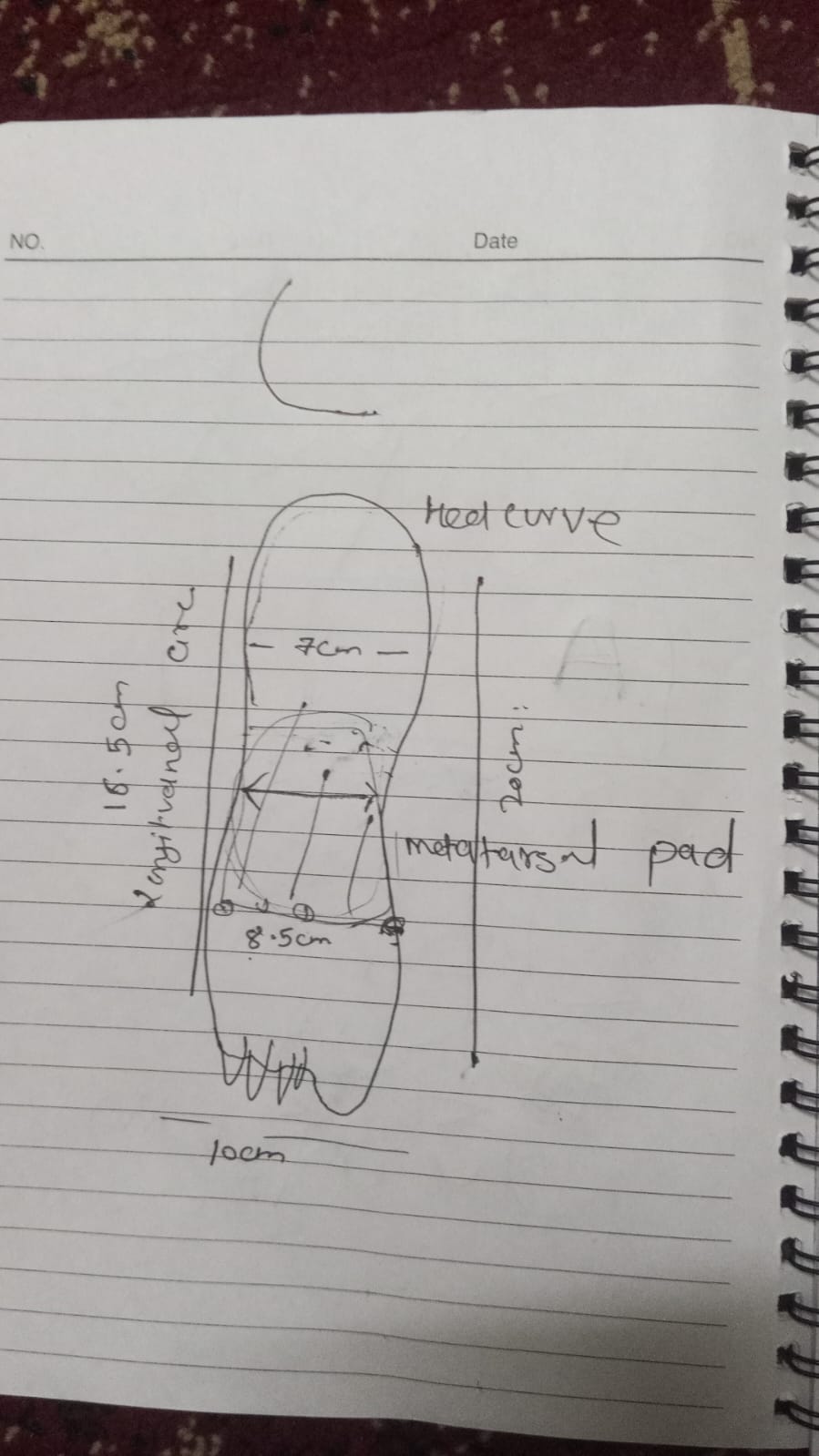

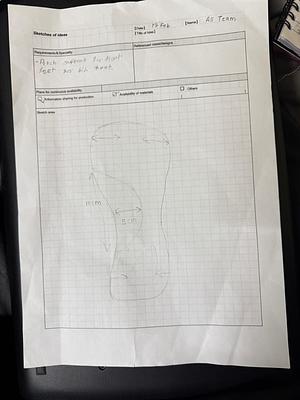

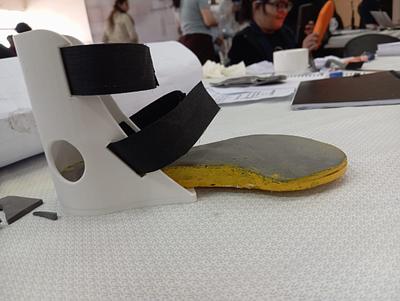

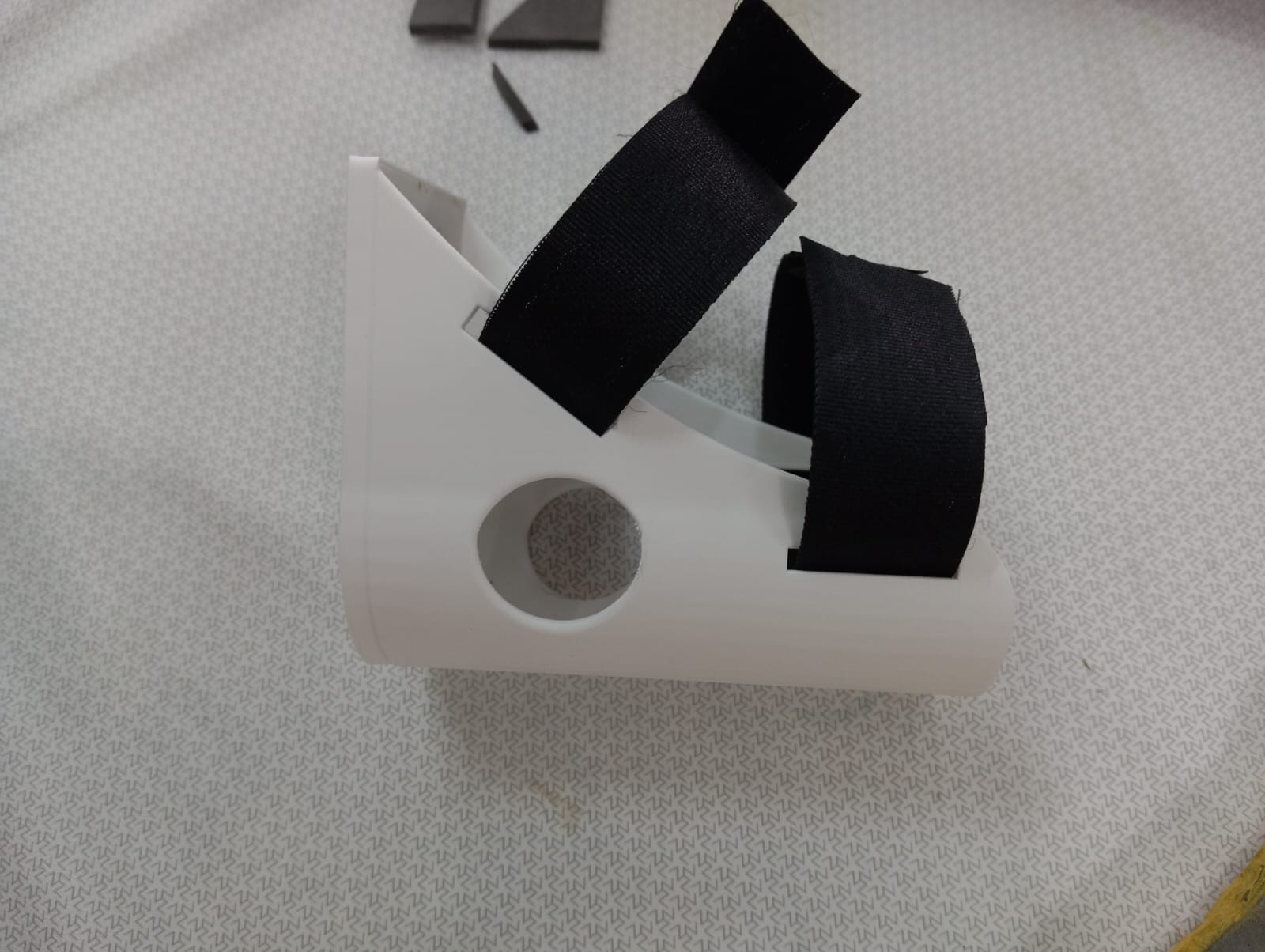

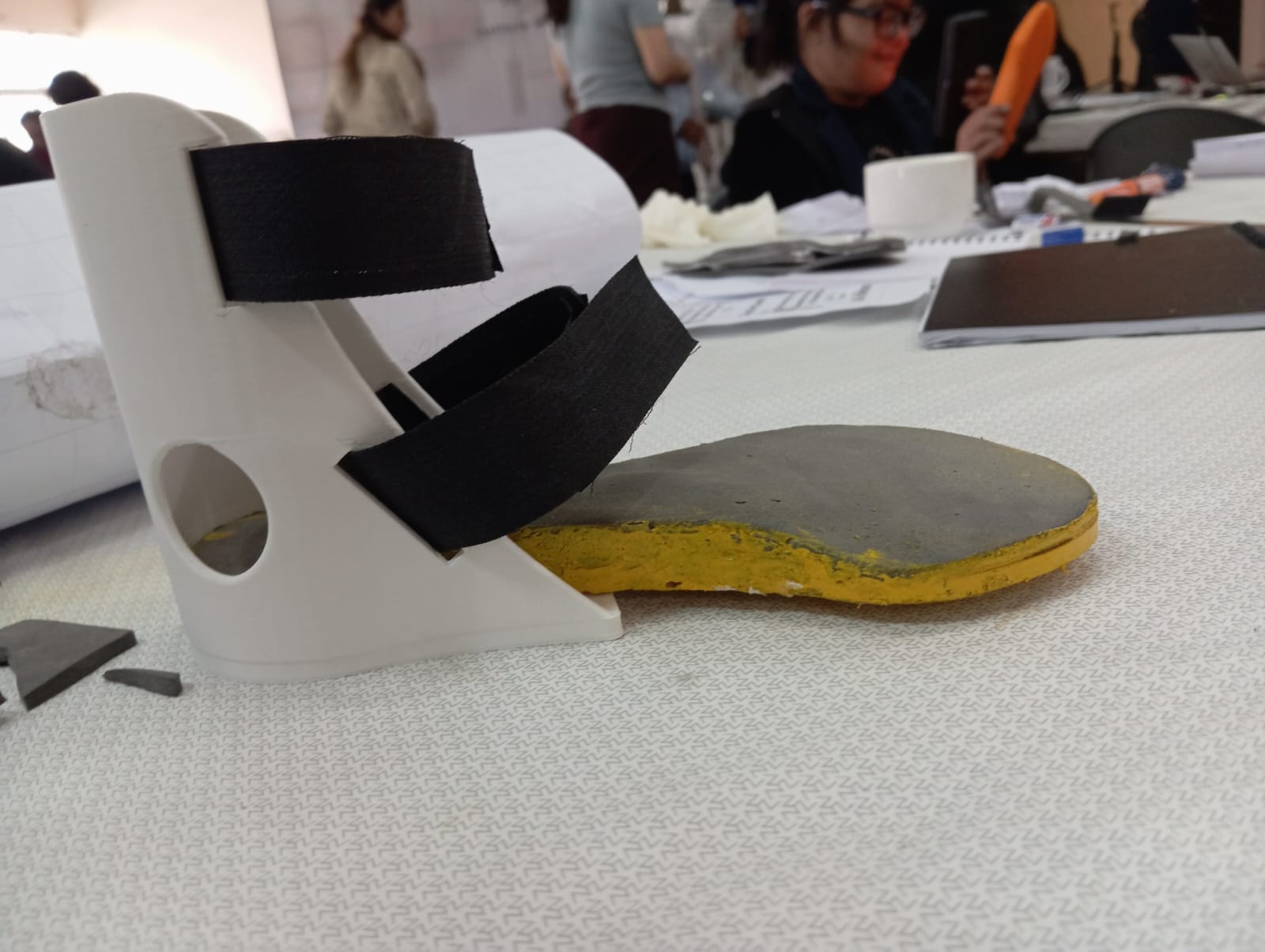

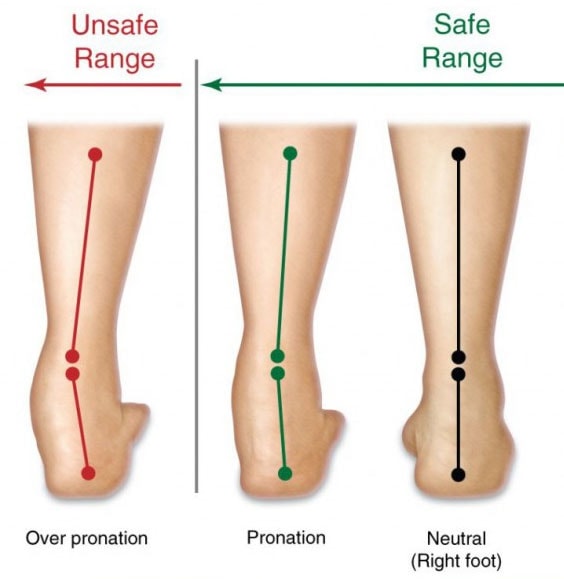

- Muscle weakness and ligamentous laxities

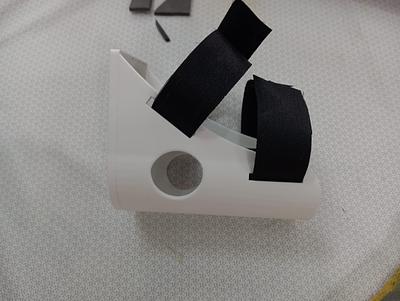

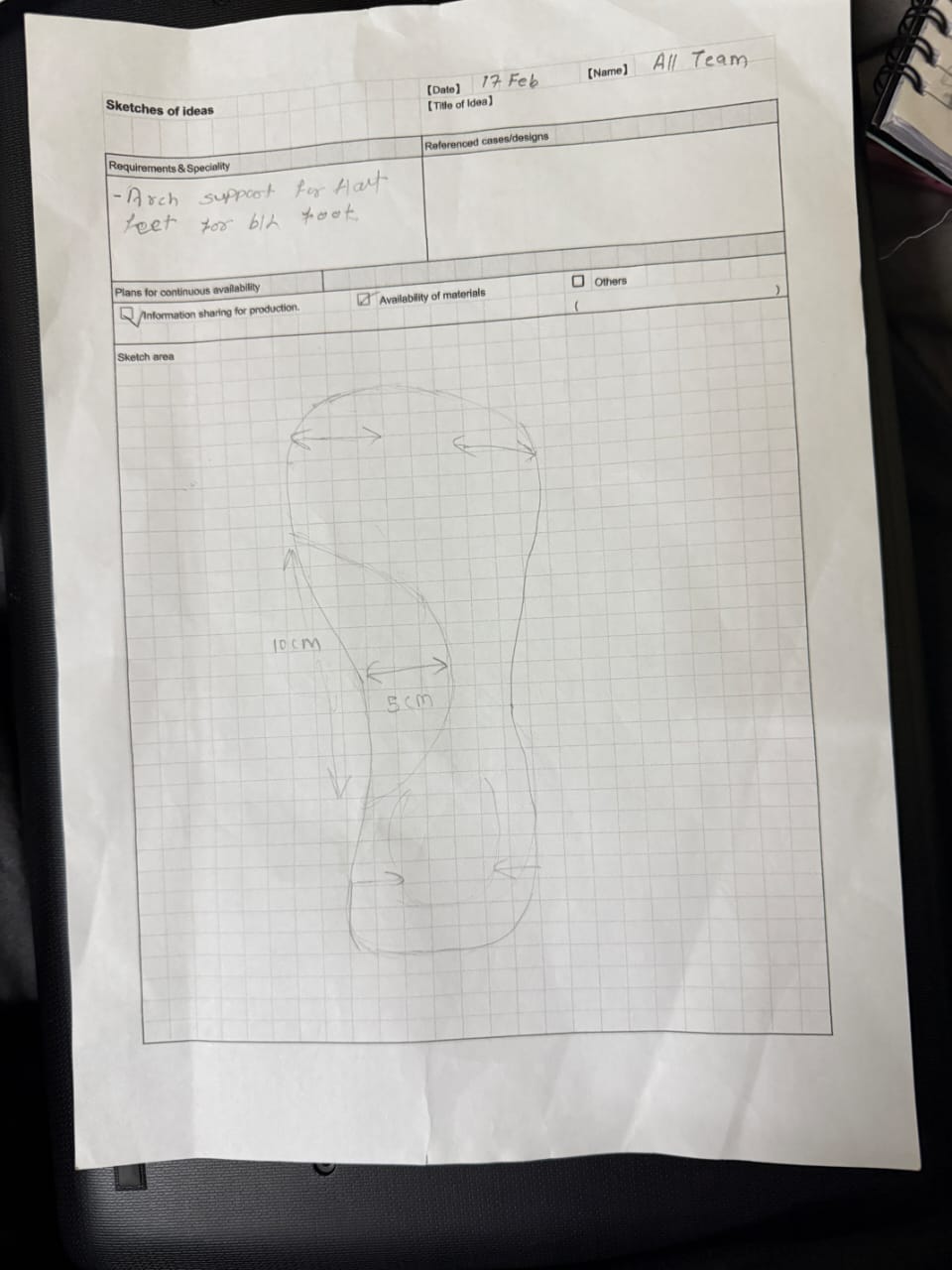

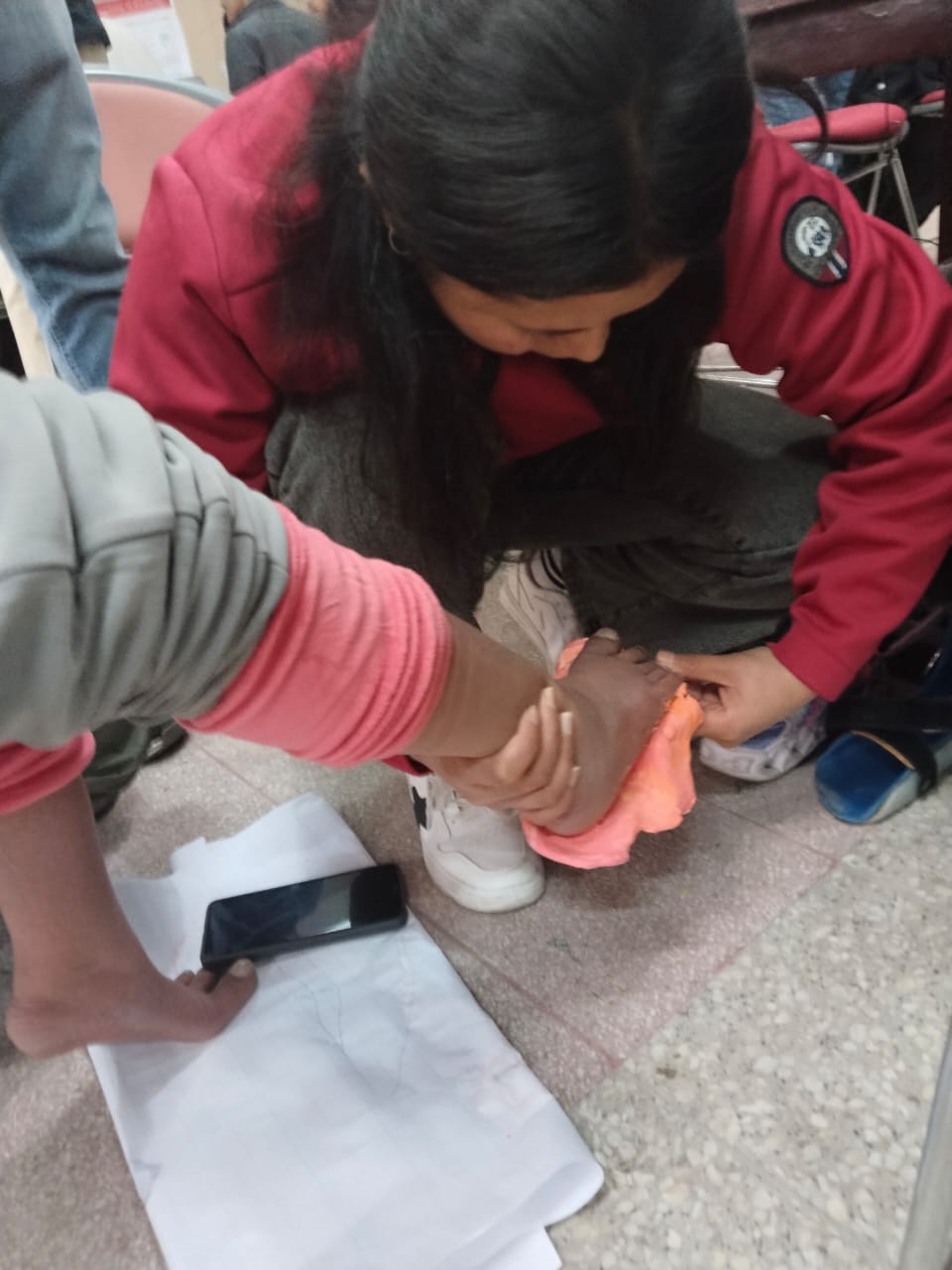

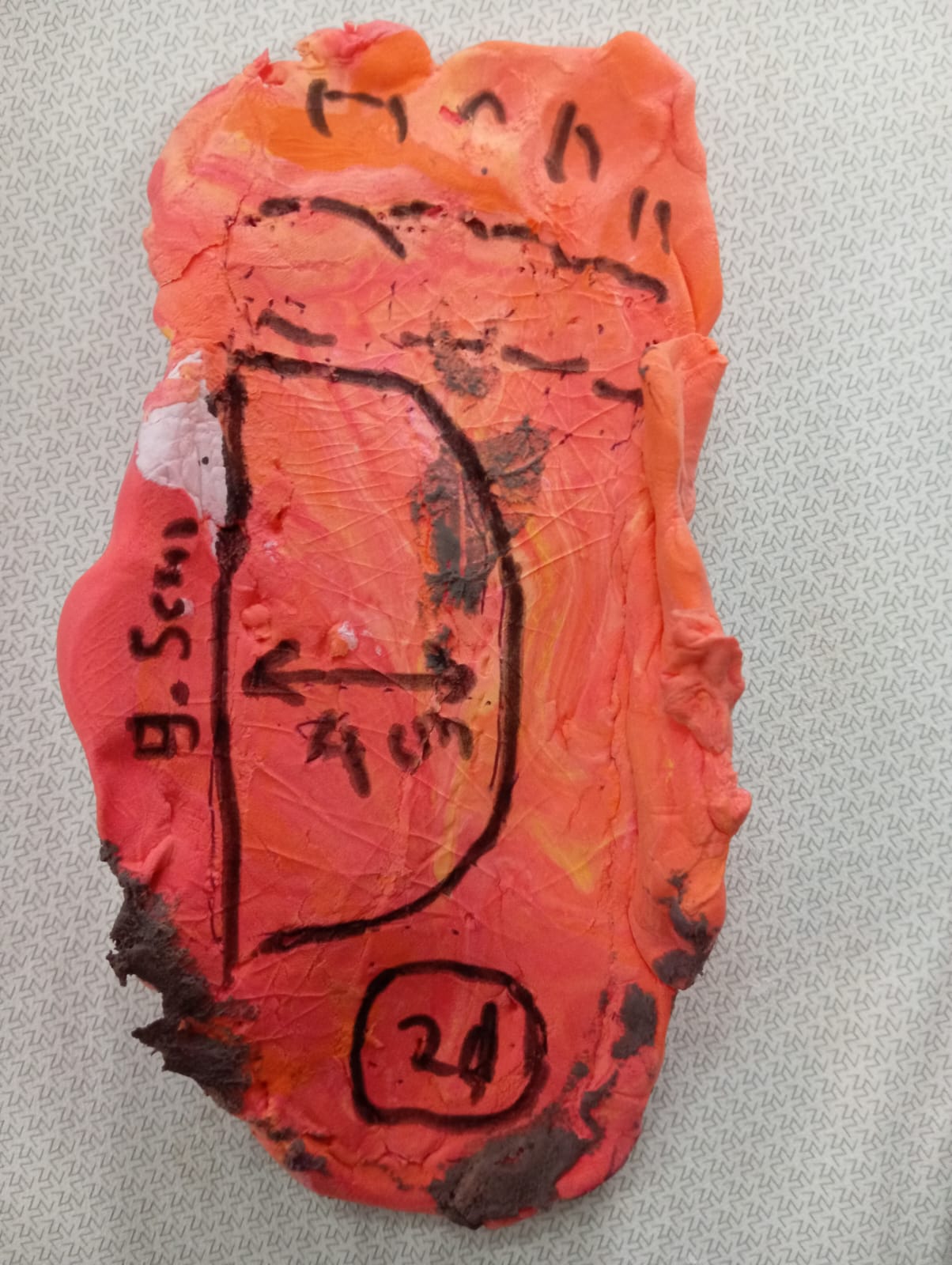

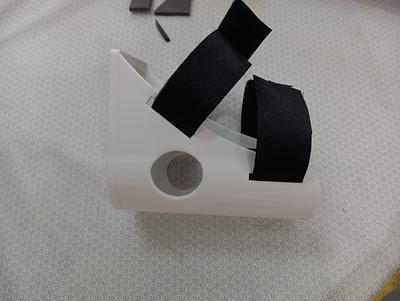

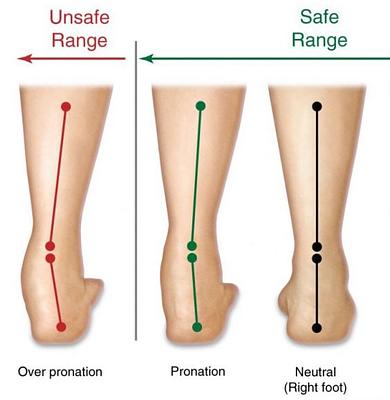

- Flat feet and everted foot, causing unequal weight distribution and knee pain.

- Poor posture and joint instabilities

- Limited walking endurance due to cardiac condition.

- Shortness of breath and high energy conservation

- Difficulty walking for extended periods.

- Previously relied on a walker but has recently achieved limited independent walking for short durations.

- Physical fatigue restricting daily activities.

- Schools express reluctance to admit her due to her medical condition and the absence of supportive infrastructure.

- Dependence on others for mobility, restricting her engagement in educational and social activities.

- Lack of inclusive facilities in schools.

- Struggles to live a normal childhood due to physical limitations.

- Parents’ concern for her education and social inclusion.

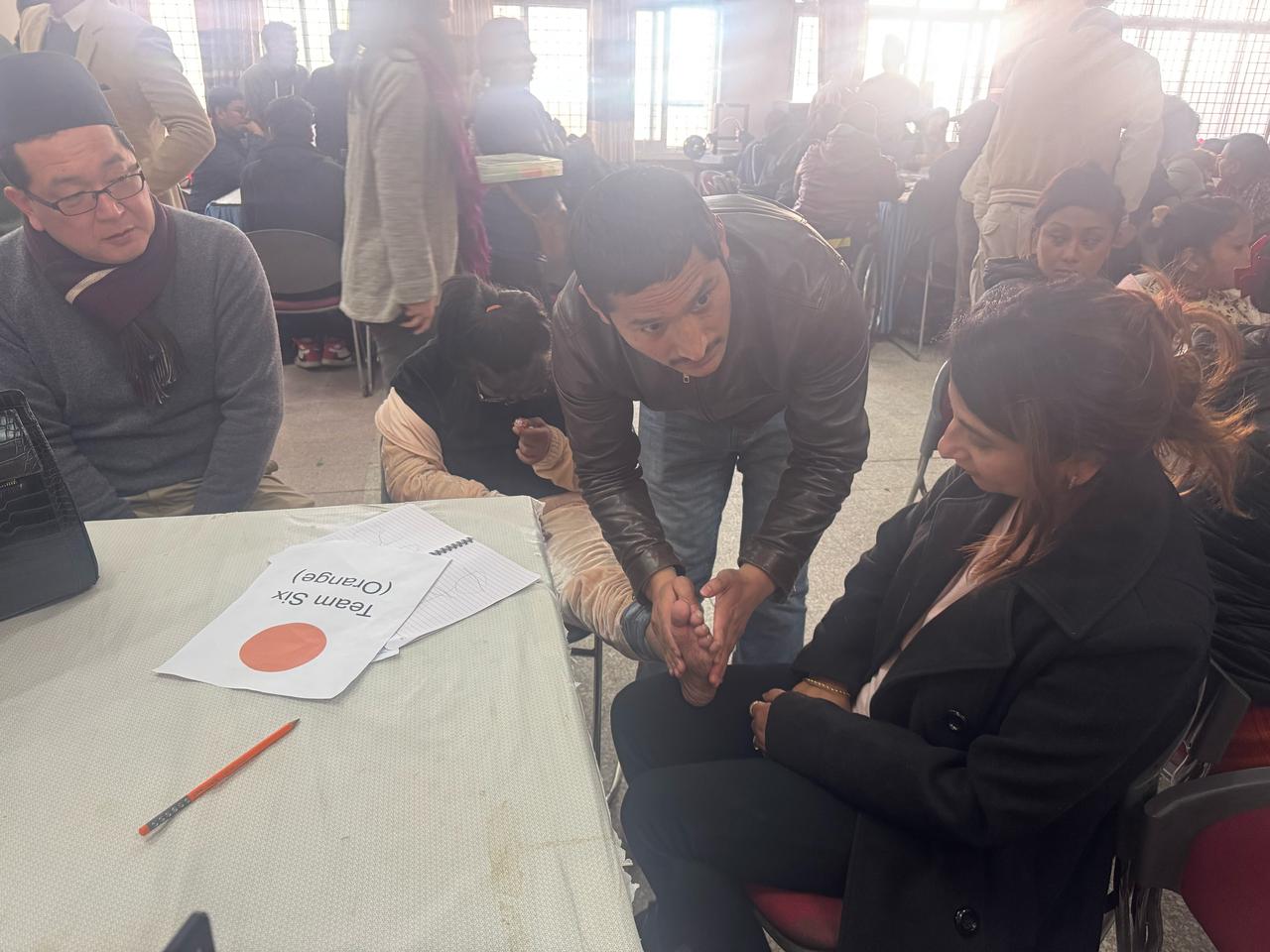

Comments